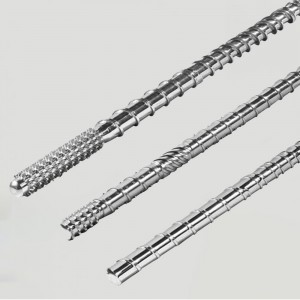

PVC Pipe screw barrel for extrusion

Screw structure: The screw usually consists of a threaded shaft and a helical groove. The threaded shaft is responsible for transmitting the rotational force, and the helical groove is responsible for extruding and mixing the plastic material. The design of the thread shape and pitch will vary according to the specific extrusion requirements.

High temperature resistance: The pipe extrusion process needs to withstand high temperature, and the screw and barrel must have high heat resistance. The selection of high-quality alloy steel materials and special heat treatment process can improve the thermal stability of the screw barrel.

High-pressure capability: Extrusion requires high pressure to be exerted on the plastic material, and the screw barrel must be able to withstand this high pressure and maintain structural stability.

High wear resistance: Due to the wear of plastics and other additives during extrusion, the screw barrel must have high wear resistance. The use of wear-resistant alloy steel materials and special surface treatment technology can enhance its wear resistance.

Feed Uniformity: During pipe extrusion, the design of the screw barrel requires uniform mixing and melting of the plastic material. Reasonable screw structure and optimized runner design can ensure the uniformity and consistency of materials.

Heating and Cooling Control: The screw barrel usually requires precise heating and cooling control to ensure the stability of the extrusion process and product quality. The design of the heating and cooling system takes into account the characteristics of the different pipe materials and the needs of the extrusion process.

In summary, the characteristics of the tube screw barrel include high temperature resistance, high pressure resistance, wear resistance, uniform feeding, heating and cooling control, etc. Choosing the right material and optimizing the design are the key factors to ensure the quality and production efficiency of pipe extrusion.

Material: High-quality alloy steel such as 38CrMoAlA or 42CrMo.

Hardness: Typically around HRC55-60.

Nitriding Treatment: Up to 0.5-0.7mm depth for enhanced surface hardness and wear resistance.

Screw Diameter: Determined by the specific panel thickness, width, and production requirements.

Screw Coating: Optional bimetallic or hard chromium plating for increased durability.

Barrel Heating: Electric heating or cast aluminum heating bands with PID temperature control.

Cooling System: Water cooling with temperature control to maintain proper operating temperature.

Screw Structure: Designed with a suitable pitch and compression ratio for efficient extrusion.