News

-

Zhejiang Xinteng Intelligent Technology Co., Ltd moves to new factory

Where is the confidence in extending the industrial chain? Is it the right way to go? Check out the report: This is the new building of Zhejiang Xinteng Intelligent Technology Co., Ltd. Steel structure of the building has been completed. Under the aerial camera, we can s...Read more -

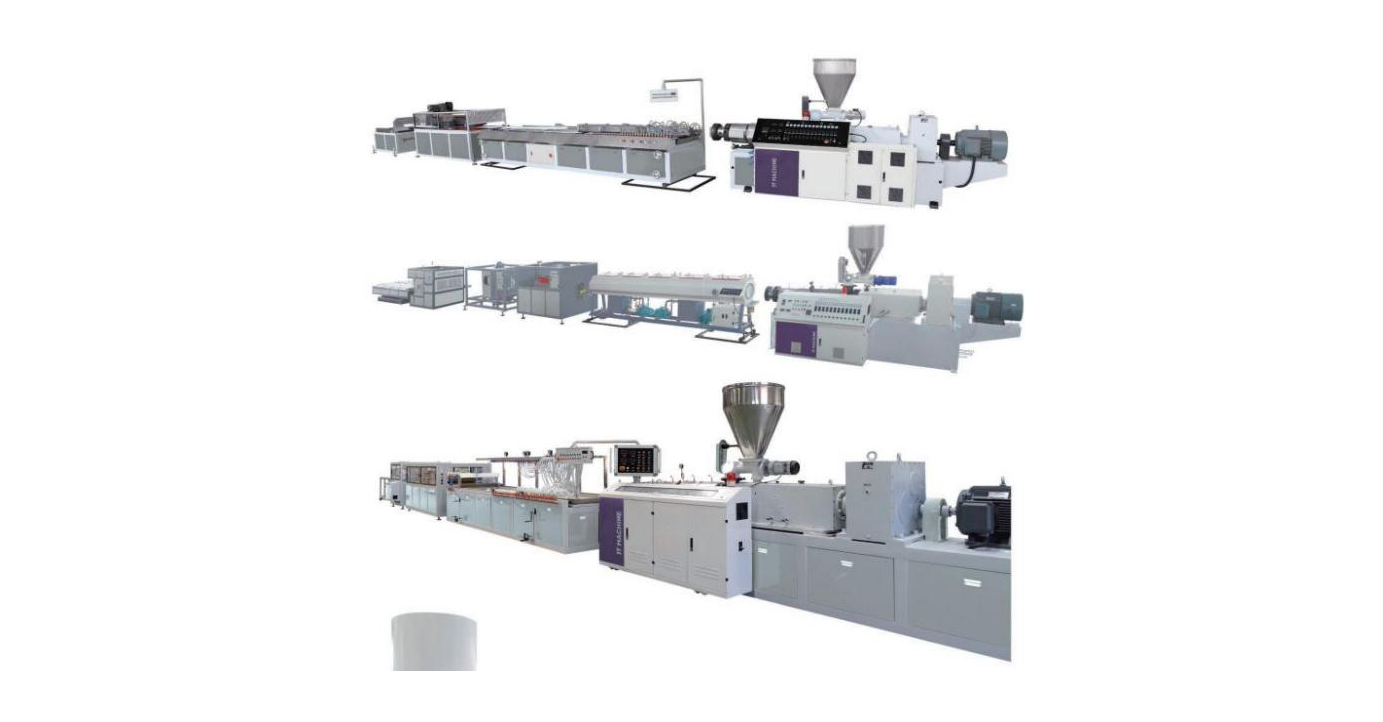

Types of extruders

Extruders can be divided into single screw, twin screw and multi screw extruder according to the number of screws. At present, the single screw extruder is the most widely used, suitable for extrusion processing of general materials. Twin screw extruder has less generate...Read more -

Hollow blow molding machine’s industry development

Blow molding machine is a very common mechanical equipment in the plastic machinery industry, and blow molding technology has been widely used all over the world. According to the parison production method, blow molding can be divided into extrusion blow molding, injecti...Read more