A PVC pipe single screw barrel plays a vital role in the plastic extrusion process, efficiently melting and shaping PVC material into strong, durable pipes. In 2022, single screw extruders dominated the market, contributing to 63.2% of the global revenue share, showcasing their reliability and extensive application. Pvc pipe single screw barrel factories and single plastic screw barrel factories specialize in crafting these components with precision, ensuring consistent and high-quality performance.

Key Features of PVC Pipe Single Screw Barrels

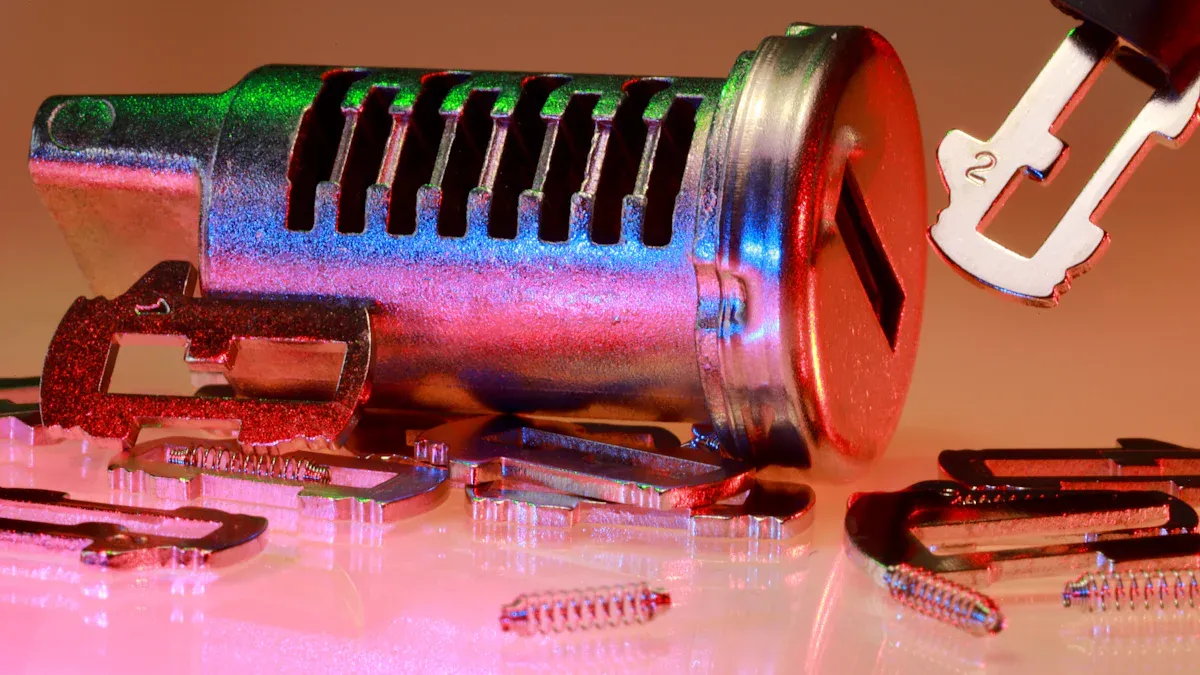

Components and Design

The design of a PVC pipe single screw barrel is both efficient and straightforward. Its structure includes a cylindrical barrel and a rotating screw, which work together to process PVC material. The screw’s helical grooves ensure proper mixing and melting of the material, while the barrel provides a controlled environment for extrusion.

Key technical specifications of these components include:

| Specification | Details |

|---|---|

| Diameter | Ф16-Ф300 |

| Aspect Ratio | L/D=15-40 |

| Structural Features | Simple structure, low cost, good mixing and plasticizing ability |

These specifications highlight the versatility of the design, making it suitable for various PVC applications. Additionally, industrial studies have shown that wall slip behavior in single-screw extruders significantly affects flow rates. Models developed for flow rate, pressure drop, and screw speed further optimize extrusion performance.

Material and Build Quality

The material used in manufacturing PVC pipe single screw barrels plays a critical role in their durability and performance. Most barrels are made from 38crMoAIA, a high-strength alloy steel known for its excellent wear resistance and toughness. The surface undergoes nitriding treatment to enhance hardness and extend the barrel’s lifespan.

Key material properties include:

- Surface Hardness: HV≥900

- Nitride Layer Depth: 0.5-0.8mm

These features ensure the barrel can withstand high temperatures and pressures during the extrusion process. The robust build quality minimizes wear and tear, reducing maintenance costs and downtime. Manufacturers like Zhejiang Jinteng Machinery Manufacturing Co., Ltd. utilize advanced CNC equipment and heat treatment technologies to achieve these high standards.

Heating and Cooling Systems

Efficient heating and cooling systems are essential for maintaining consistent temperatures during the extrusion process. The barrel’s heating system ensures that PVC material melts evenly, while the cooling system prevents overheating and maintains product quality.

Studies analyzing the effects of screw speed and temperature on extrusion performance have demonstrated the importance of precise temperature control. Temperature-pressure transducers installed before and after the breaker plate monitor conditions in real-time, ensuring optimal performance. Adjustments to screw speed, melt temperature, and flow rate directly impact the quality of the final product.

These systems not only improve efficiency but also enhance the consistency of the extrusion process, making PVC pipe single screw barrels a reliable choice for manufacturers.

How PVC Pipe Single Screw Barrels Work

The Role of the Screw in PVC Extrusion

The screw in a PVC pipe single screw barrel serves as the backbone of the extrusion process. It facilitates the movement, melting, and mixing of PVC material within the barrel. The helical design of the screw ensures uniform distribution of heat and pressure, which is critical for achieving consistent product quality.

- Optimized screw designs have demonstrated remarkable efficiency improvements. For instance:

- Production throughput doubled from 4.5 tons to 8.5 tons per shift in a real-world application.

- Enhanced flexibility in processing various materials and additives improved product quality.

- Tailored screw designs reduced material usage, increasing profitability.

Scholarly research further underscores the importance of screw design. Mathematical models and experimental studies confirm that barrier screws optimize melting performance and extrusion outcomes. These findings highlight the screw’s pivotal role in ensuring the efficiency and reliability of PVC pipe manufacturing.

Melting and Mixing Process

The melting and mixing process within a PVC pipe single screw barrel is a carefully engineered sequence. As PVC material enters the barrel, the screw’s rotation generates friction and heat, gradually melting the material. The helical grooves on the screw facilitate thorough mixing, ensuring additives and fillers are evenly distributed.

- Studies evaluating barrier-screw extruders reveal their effectiveness in improving polymer extrusion, including PVC.

- Research on plasticating sequences provides experimental data supporting the optimization of extrusion processes.

Temperature control plays a vital role in this process. Precise adjustments to screw speed and melt temperature ensure the material reaches the desired consistency. This meticulous approach minimizes defects and enhances the overall quality of the final product.

Ensuring Efficiency and Consistency

Efficiency and consistency are paramount in PVC pipe extrusion. Manufacturers employ advanced methodologies to maintain process stability and reduce variability. Statistical Process Control (SPC) identifies variations and stabilizes processes, while Six Sigma’s DMAIC approach further refines production capabilities.

- Real-world data illustrates the impact of process optimization:

- A data acquisition system reduced scrap rates from 15% to 5% within three months.

- Real-time monitoring prevented off-spec products, ensuring high-quality standards.

- The system’s cost-effectiveness was evident as it quickly paid for itself through reduced waste.

These strategies not only improve efficiency but also ensure consistent product quality, making PVC pipe single screw barrels indispensable in modern manufacturing.

Advantages of PVC Pipe Single Screw Barrels

Simplicity and Cost-Effectiveness

PVC pipe single screw barrels are widely recognized for their straightforward design and cost-efficient operation. Their simple structure minimizes mechanical failures, making them ideal for manufacturers seeking reliable and steady performance. Single screw extruders consistently deliver uniform pressure and output rates, which are essential for producing high-quality PVC pipes.

- Key benefits include:

- Reduced initial investment due to their uncomplicated design.

- Lower operational costs compared to more complex systems.

- High suitability for standard processing tasks, such as pipe and sheet production.

In 2024, single screw extruders accounted for 62.7% of market revenue, underscoring their dominance in small to medium-scale operations. Their affordability and reliability make them a preferred choice for many manufacturers.

Maintenance and Durability

The durability of PVC pipe single screw barrels stems from their robust construction and advanced materials. High-strength alloys, combined with hardened coatings, enhance resistance to wear and corrosion caused by PVC’s abrasive nature.

| Factor | Description |

|---|---|

| Type of Plastic | Corrosive nature of PVC affects wear. |

| Hardened Coating | Coatings improve resistance and longevity. |

| Process Settings | Proper temperature and pressure reduce wear. |

Implementing preventive maintenance programs further extends the lifespan of these barrels. Regular alignment checks and employee training on wear measurement ensure consistent performance over time.

Comparison to Twin Screw Barrels

Single screw barrels differ significantly from twin screw systems in design, cost, and maintenance. While twin screw barrels excel in specialized applications, single screw barrels offer simplicity and reliability for standard processes.

| Feature | Single Screw Barrels | Twin Screw Barrels |

|---|---|---|

| Design | Simple, reduces mechanical failure | Complex, higher failure risk |

| Maintenance | Easy, less technical expertise required | More complex repairs |

| Operational Costs | Minimal due to efficient design | Higher due to complexity |

Single screw barrels also provide easier temperature control and are more suitable for changing coating varieties. These advantages make them a practical choice for manufacturers prioritizing cost-effectiveness and operational efficiency.

Applications of PVC Pipe Single Screw Barrels

Construction and Plumbing

PVC pipe single screw barrels play a crucial role in the construction and plumbing industries. These barrels enable the production of high-quality PVC pipes, which are widely used for water supply, drainage, and sewage systems. Their ability to produce pipes with consistent wall thickness and smooth surfaces ensures reliable performance in demanding applications.

Builders and contractors prefer PVC pipes for their lightweight nature, corrosion resistance, and ease of installation. The precision offered by single screw barrels ensures that pipes meet stringent industry standards, making them a trusted choice for residential, commercial, and industrial projects.

Electrical Conduits and Industrial Piping

Electrical conduits and industrial piping systems rely heavily on PVC pipes manufactured using single screw barrels. These barrels ensure uniformity in pipe dimensions, which is critical for applications requiring precise fittings and connections.

Performance studies highlight the impact of various parameters on extrudate properties during the extrusion process. The table below summarizes key findings:

| Parameter | Effect on Extrudate Properties |

|---|---|

| DDGS Levels | Significant decrease in die pressure with higher levels |

| Moisture Content | Significant differences in color and expansion ratio |

| Die Dimensions (L/D ratios) | Affects die pressure and expansion ratio |

| Screw Compression Ratios | Higher compression leads to significant changes in properties |

| Processing Conditions | Influences extruder torque, die pressure, and mass flow rate |

These insights demonstrate how optimized processing conditions and screw designs enhance the quality of PVC pipes for electrical and industrial applications. The resulting pipes exhibit excellent durability, chemical resistance, and thermal stability, making them ideal for protecting electrical wiring and transporting industrial fluids.

Other Industry-Specific Uses

Beyond construction and electrical applications, PVC pipe single screw barrels support a variety of specialized industries. Agricultural irrigation systems benefit from the lightweight and weather-resistant properties of PVC pipes. In the automotive sector, these pipes are used for fluid transfer systems due to their chemical resistance and flexibility.

The food and beverage industry also utilizes PVC pipes for non-toxic and hygienic fluid transport. The versatility of single screw barrels allows manufacturers to tailor pipe properties to meet the unique requirements of each industry, ensuring optimal performance and reliability.

PVC pipe single screw barrels exemplify precision engineering, combining optimized screw geometry and functional zones to enhance extrusion efficiency. Their robust design ensures consistent melt temperature profiles, improving product quality and reducing waste. These barrels play a pivotal role in PVC pipe manufacturing, supporting diverse applications across construction, plumbing, and industrial sectors, while driving cost-effective and reliable production processes.

FAQ

What is the lifespan of a PVC pipe single screw barrel?

The lifespan depends on usage and maintenance. High-quality barrels, like those made from 38crMoAIA alloy steel, typically last several years with proper care.

How does temperature control impact extrusion quality?

Precise temperature control ensures uniform melting and mixing of PVC material. This reduces defects and enhances the consistency of the final product.

Can single screw barrels handle different PVC formulations?

Yes, single screw barrels adapt to various PVC formulations. Their design supports efficient processing of additives and fillers, ensuring optimal extrusion performance.

Post time: Jun-05-2025