The plastic injection molding screw barrel stands at the heart of every molding process. When they choose a high-quality Plastic Machine Screw Barrel or a Plastic Twin Screw Extruder Barrel, manufacturers see smoother material flow, fewer defects, and lower costs. Stainless Steel Twin Screw Extruder Barrel options also help extend equipment life and cut downtime.

Key Roles of the Plastic Injection Molding Screw Barrel

Melting and Homogenizing Plastic Material

The plastic injection molding screw barrel plays a huge part in turning solid plastic pellets into a smooth, molten material. Inside the barrel, the screw rotates and pushes the pellets forward. As the pellets move, friction and heater bands melt them. The barrel keeps the heat even, so the plastic melts at the right rate. This process helps avoid lumps or cold spots in the material.

Tip: The screw barrel has three main zones—feed, compression, and metering. Each zone has a special job. The feed zone moves and preheats the pellets. The compression zone melts the plastic and removes air. The metering zone makes sure the melt is smooth and ready for injection.

| Zone | Primary Functions |

|---|---|

| Feed Zone | Transports pellets, preheats them, and compacts to remove air pockets. |

| Compression Zone | Melts the plastic and removes air through pressure and shear. |

| Metering Zone | Homogenizes the melt, builds pressure, and stabilizes flow for injection. |

Temperature control matters a lot. For example, rigid UPVC needs careful heating between 180-190°C. The screw barrel uses both external heaters and the screw’s own movement to create the right amount of heat. This balance keeps the plastic from burning or sticking. The screw’s speed also affects how well the plastic melts. If the screw turns too slowly, the melt might not get hot enough. If it turns too fast, the plastic could overheat. The plastic injection molding screw barrel makes sure the melt is just right for every shot.

Mixing Additives and Ensuring Color Consistency

Manufacturers often add colorants or special additives to plastics. The plastic injection molding screw barrel mixes these ingredients into the melt. The screw’s design, with special mixing sections, helps blend everything evenly. This mixing stops streaks or spots from showing up in the final product.

Color consistency can be tricky. Sometimes, dry pigments stick inside the hopper or don’t mix well. Humidity can mess with resin and pigment quality. Precise dosing of colorants is important. Machines use gravimetric blenders to measure the right amount. Mold design also helps keep colors even across different parts.

Note: Advanced screw designs, like barrier or Maddock screws, break up lumps and spread colorants better. These designs can boost mixing efficiency by over 20% and cut scrap rates by up to 30%. Regular cleaning and maintenance keep the screw barrel working at its best, so colors stay true from batch to batch.

Conveying and Injecting Molten Plastic

Once the plastic is melted and mixed, the screw barrel moves the molten material toward the mold. The screw rotates inside the heated barrel, pushing the melt forward. When enough material builds up, the screw acts like a plunger. It injects the molten plastic into the mold at high pressure.

Here’s how the process works:

- Plastic pellets enter the feed section and move forward as the screw turns.

- Friction and heat melt the pellets.

- The screw compresses the melt, making sure it’s smooth and even.

- The screw advances and injects the molten plastic into the mold.

The plastic injection molding screw barrel keeps everything moving smoothly. It controls the pressure and flow, so each shot fills the mold perfectly. The barrel’s tough materials stand up to wear and tear, making sure the process stays reliable over time.

Optimizing Performance with the Right Plastic Injection Molding Screw Barrel

Impact of Screw Geometry and Barrel Design

Screw geometry shapes how plastic melts and mixes inside the barrel. The length, thread shape, pitch, and speed of the screw all play a role. When engineers adjust these parameters, they can control how much heat and shear the plastic receives. This helps create a uniform melt and reduces defects like streaks or bubbles.

The compression ratio, which compares the depth of the screw’s feed and metering zones, affects how tightly the plastic is packed. A higher ratio increases density and mixing but may not suit heat-sensitive plastics. Back pressure also matters. It pushes the molten resin harder, breaking up unmelted bits and improving mixing. However, too much back pressure can damage delicate materials.

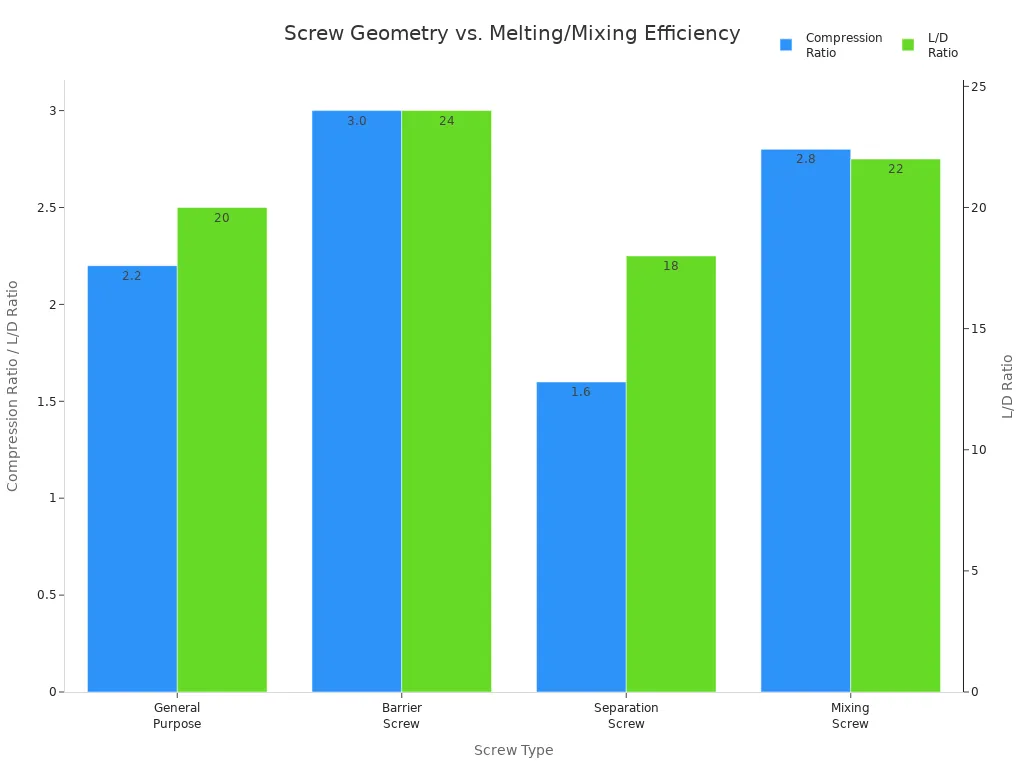

Here’s a table showing how different screw types and their geometry affect melting and mixing efficiency:

| Screw Type | Suitable Materials | Compression Ratio | L/D Ratio | Typical Use | Effect on Melting and Mixing Efficiency |

|---|---|---|---|---|---|

| General Purpose | ABS, PP, PE | 2.2:1 | 20:1 | Appliance Housings | Versatile melting and mixing with moderate shear and uniformity. |

| Barrier Screw | PA+GF, PC | 3.0:1 | 24:1 | Structural Parts | High shear and mixing, better melt homogeneity and product quality. |

| Separation Screw | PVC, POM | 1.6:1 | 18:1 | Pipes, Components | Controls shear, reduces degradation, ensures consistent melting. |

| Mixing Screw | PMMA, PC+GF | 2.8:1 | 22:1 | Light Covers | Enhanced mixing, uniform melt, improved optical properties. |

Engineers often use charts to compare screw geometry. The chart below shows how compression ratio and L/D ratio vary for different screw types:

A well-designed Plastic Injection molding screw barrel with the right geometry ensures stable plasticization, consistent melt temperature, and smooth material flow. This leads to better surface gloss, fewer defects, and stronger molded parts.

Material Selection for Durability and Wear Resistance

Choosing the right materials for the screw barrel makes a big difference in how long it lasts and how well it performs. Manufacturers use tough steels and advanced coatings to fight wear and corrosion. For example, 38CrMoAlA nitrided steel works well for standard jobs, while SKD61 (H13) tool steel handles tough engineering resins. Bimetallic barrels with tungsten carbide or nickel-based alloys offer the highest resistance to abrasion and chemicals.

| Material Type | Wear Resistance | Corrosion Resistance | Typical Hardness | Application Highlights |

|---|---|---|---|---|

| 38CrMoAlA Nitrided Steel | ★★★☆☆ | ★★☆☆☆ | ~1000 HV (Nitrided) | Reliable for standard applications |

| SKD61 (H13) Tool Steel | ★★★★☆ | ★★★☆☆ | 48–52 HRC | Tough engineering resins, thermal stress |

| Bimetallic Barrels | ★★★★★ | ★★★★☆ | 60–68 HRC | Abrasive, fiberglass, flame retardant, recycled plastics |

Other popular choices include AISI 4140 and 4340 alloy steels for general use, D2 and CPM tool steels for abrasive plastics, and Hastelloy or Inconel for corrosive environments. Surface treatments like nitriding and chromium plating boost hardness and lifespan. When manufacturers select the right material, they reduce downtime and maintenance costs, keeping production running smoothly.

Tip: Bimetallic barrels with high tungsten carbide content last much longer, especially when processing abrasive or filled polymers.

Matching Screw Barrel to Different Plastics

Not all plastics behave the same way during molding. Each type needs a specific screw barrel design to get the best results. Engineers look at the plastic’s melting temperature, viscosity, and stability. They match screw geometry, groove depth, and barrel coatings to the material’s needs.

For example, polycarbonate (PC) requires a long screw with a gradual compression ratio and a mixing section to prevent degradation. Nylon (PA) needs a mutant screw with a high compression ratio and a small gap between screw and barrel to control shear. PVC demands a corrosion-resistant barrel and a low-shear screw to avoid overheating and material buildup.

| Plastic Type | Screw Design Parameters | Impact on Quality |

|---|---|---|

| Polycarbonate (PC) | Large L/D ratio (~26), gradual screw, compression ratio ~2.6, mixing section | Good plasticizing, prevents degradation, improves homogeneity |

| Nylon (PA) | Mutant screw, L/D 18-20, compression ratio 3-3.5, small gap | Prevents overheating, controls shear, maintains melt quality |

| PMMA | Gradual screw, L/D 20-22, compression ratio 2.3-2.6, mixing ring | Accurate melting, prevents moisture issues, maintains precision |

| PET | L/D ~20, low shear screw, compression ratio 1.8-2, no mixing zone | Prevents overheating, controls shear, suitable for recycled materials |

| PVC | Low shear screw, corrosion-resistant barrel, L/D 16-20, no check ring | Prevents overheating and corrosion, stable temperature control |

Matching the Plastic Injection molding screw barrel to the plastic type helps avoid defects like discoloration, incomplete melting, or warping. It also improves cycle times and energy efficiency.

Note: Upgrading screw barrels for specific plastics can boost throughput by up to 25% and reduce defects, saving time and money.

Maintenance Tips for Longevity and Reliability

Regular maintenance keeps the screw barrel working at its best. Operators should inspect the barrel for wear, scratches, or pitting whenever the screw is removed. Cleaning with commercial purging compounds removes residue and prevents carbon buildup. Monitoring pressure, temperature, and screw speed helps spot problems early.

Here are some practical maintenance tips:

- Inspect the screw barrel visually and with gauges every time the screw is removed.

- Clean the barrel weekly for continuous runs, or every 2-3 days if changing plastics often.

- Lubricate moving parts daily and grease them weekly with high-quality grease.

- Use pure raw materials and store them properly to avoid contamination.

- Train operators to recognize wear signs and keep detailed maintenance logs.

- Stock spare parts to minimize downtime.

- After shutdown, run the screw at low speed to distribute residual plastic, clean with special detergents, and apply protective oil.

Callout: Bimetallic barrels with iron-based liners can last three times longer than standard screws. Proper alignment and lubrication extend lifespan and reduce maintenance frequency.

A well-maintained Plastic Injection molding screw barrel delivers consistent quality, reduces downtime, and supports efficient production.

The Plastic Injection molding screw barrel plays a key role in delivering consistent product quality and efficient production.

- High-quality screw barrels improve melt consistency, reduce scrap, and boost efficiency.

- Regular maintenance prevents downtime and extends equipment life.

- Material and energy savings add up quickly.

- Faster changeovers increase capacity and profits.

FAQ

What signs show a screw barrel needs replacement?

Operators notice uneven melt, increased defects, or slow cycles. They also see visible wear, scratches, or pitting inside the barrel.

How often should someone clean a screw barrel?

Most manufacturers clean the barrel weekly. If they switch plastics often, they clean it every two to three days.

Can one screw barrel work for all plastics?

No, each plastic type needs a specific screw barrel design. Using the right match improves product quality and reduces waste.

Post time: Aug-15-2025