You see the results of China’s drive for excellence every time you encounter plastic extrusion products. Factories in China use modern machines and smart systems to create high-quality goods at lower costs.

China’s skilled workers and strong support from the government help the country stay ahead in this industry. You notice innovation and adaptability in every stage of production.

Key Takeaways

- China’s strong domestic supply of petrochemicals ensures steady access to raw materials, helping you avoid delays and reduce costs.

- Efficient logistics networks in China allow for quick delivery of materials, keeping production lines running smoothly and reducing storage costs.

- A skilled workforce in China operates plastic extrusion machines efficiently, allowing for high productivity and lower labor costs.

- Large-scale production facilities in China enable economies of scale, reducing per-unit costs and allowing competitive pricing for products.

- Government support through research funding and tax incentives helps manufacturers innovate and improve production processes.

- Automation in factories enhances production speed and accuracy, leading to fewer errors and higher quality products.

- Collaboration among companies in manufacturing clusters fosters innovation and provides access to shared resources, lowering operational costs.

- Continuous education and training programs ensure workers stay updated on the latest technologies and practices in the plastic extrusion industry.

Cost Advantages in Plastic Extrusion

Abundant Raw Materials

Domestic supply of petrochemicals

You benefit from China’s strong domestic supply of petrochemicals when you work in plastic extrusion. Many large chemical companies in China produce the raw materials you need, such as polyethylene and polypropylene. This steady supply helps you avoid delays and keeps your costs low. You do not have to rely on imports, so you can plan your production with confidence.

Efficient logistics for material sourcing

You also gain from China’s efficient logistics network. Trains, trucks, and ships move raw materials quickly from factories to plastic extrusion plants. You can order what you need and receive it fast. This system reduces storage costs and helps you keep your production lines running smoothly.

Tip: When you have easy access to raw materials, you can respond faster to customer orders and market changes.

Competitive Labor Costs

Skilled workforce at lower wages

You find many skilled workers in China who know how to operate plastic extrusion machines. These workers train in vocational schools and learn on the job. Their wages are lower than in many other countries, so you can keep your labor costs down while still getting quality work.

High labor productivity

You notice that workers in China’s plastic extrusion industry work efficiently. They use modern tools and follow clear processes. This high productivity means you can produce more products in less time. You save money and meet customer demands quickly.

Economies of Scale in Plastic Extrusion

Large-scale production facilities

You see that many plastic extrusion factories in China are very large. These factories can produce huge amounts of plastic products every day. When you run a big operation, you can buy materials in bulk and use machines more efficiently.

Reduced per-unit costs

You benefit from lower costs for each product you make. When you produce more items, your fixed costs—like rent and equipment—spread out over more units. This means you can offer competitive prices to your customers and still make a profit.

- Here is a simple table to show how economies of scale work:

| Production Volume | Cost per Unit |

|---|---|

| 1,000 units | $2.00 |

| 10,000 units | $1.20 |

| 100,000 units | $0.80 |

You can see that as you increase your production, your cost per unit drops. This advantage helps you succeed in the global plastic extrusion market.

Technological Advancements in Plastic Extrusion

Investment in Research and Development

Government-funded research programs

You see strong support from the Chinese government for research in plastic extrusion. Many universities and research centers receive funding to study new materials and improve production methods. You benefit from these programs because they help factories develop better products and more efficient processes. When you work in this industry, you notice that government grants often lead to new discoveries and faster innovation.

Private sector innovation

You also find that private companies invest heavily in research and development. Many businesses set up their own labs to test new plastics and design advanced extrusion machines. You see engineers working together to solve problems and create new solutions. This teamwork helps you stay ahead of competitors and respond quickly to changes in the market.

Note: When you combine government support with private innovation, you get a powerful engine for progress in plastic extrusion.

Rapid Adoption of New Extrusion Technologies

Automation in extrusion processes

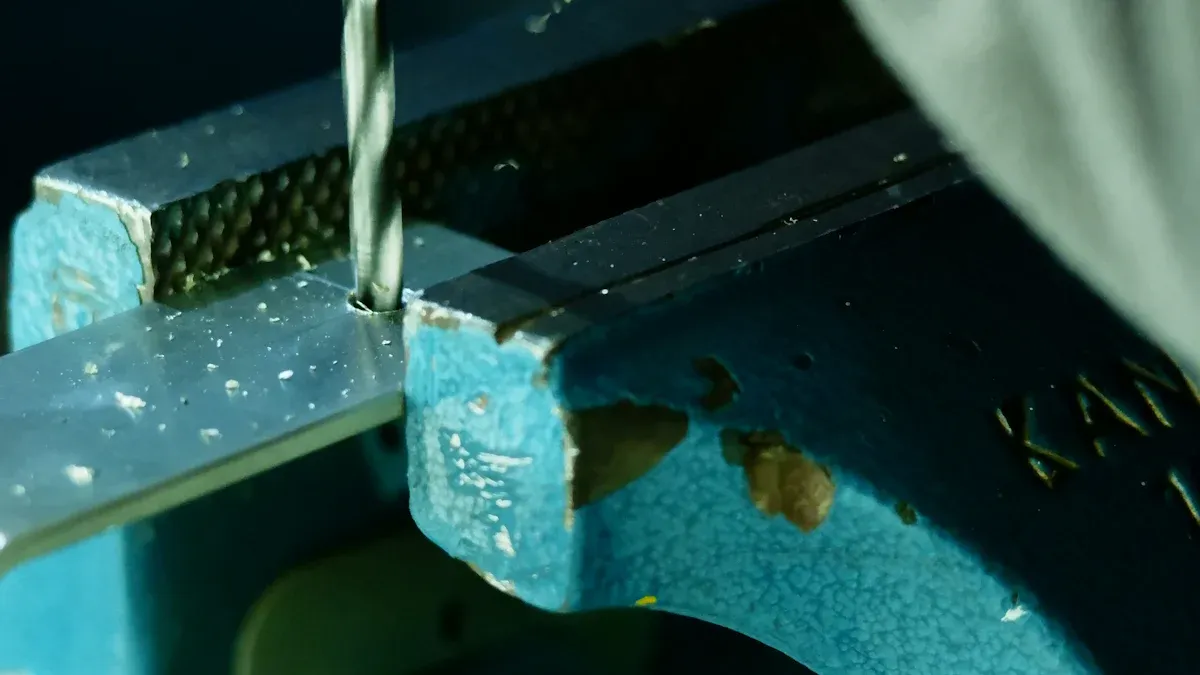

You notice that factories in China use automation to make plastic extrusion faster and more reliable. Robots and computer systems control many steps in production. You see machines that measure, cut, and shape plastic with high accuracy. Automation helps you reduce mistakes and save time. You can produce more products with fewer workers and keep quality high.

Advanced machinery and equipment

You find that Chinese manufacturers invest in the latest extrusion machines. These machines use new designs and better materials to work longer and more efficiently. You see equipment that can handle different types of plastics and create complex shapes. When you use advanced machinery, you can offer more choices to your customers and meet special requests.

- Here is a simple list of benefits you get from new technologies:

- Faster production speeds

- Lower error rates

- More product options

- Easier maintenance

Focus on High Efficiency and Energy Saving

Development of energy-efficient extruder products

You see a strong push for energy-saving solutions in plastic extrusion. Many companies design extruders that use less electricity and produce less waste. You notice that these machines help you lower your operating costs and reduce your impact on the environment. When you choose energy-efficient equipment, you save money and support green manufacturing.

Integration with strategic new industries

You find that plastic extrusion connects with other growing industries in China. Many factories work with companies in electronics, construction, and automotive sectors. You see new uses for extruded plastics in smart devices, building materials, and car parts. This integration helps you discover new markets and expand your business.

Tip: When you focus on efficiency and connect with new industries, you keep your company strong and ready for future growth.

Industrial Ecosystem Supporting Plastic Extrusion

Dense Supplier Networks

Proximity of raw material suppliers

You benefit from having raw material suppliers close to your factory. Many suppliers set up their businesses near major production areas. This means you can get the materials you need quickly. You do not have to wait long for deliveries. When you need more plastic pellets or additives, you can place an order and receive it fast. This setup helps you keep your production on schedule.

Specialized component manufacturers

You also find many companies that make special parts for your machines. These manufacturers focus on items like screws, barrels, and dies. You can choose from many options and find the right parts for your needs. If your machine breaks, you can get a replacement part quickly. This support helps you avoid long downtimes and keeps your factory running smoothly.

Integrated Manufacturing Clusters

Collaboration among related industries

You work in areas where many factories and businesses group together. These clusters include companies that make machines, supply materials, and offer services. You can share ideas and learn from others. When you face a problem, you can ask nearby experts for help. This teamwork makes your business stronger.

Shared infrastructure and services

You use shared roads, power supplies, and water systems in these clusters. Many factories use the same warehouses and shipping centers. This shared infrastructure lowers your costs. You do not have to build everything yourself. You can focus on making quality products and growing your business.

Tip: When you join a manufacturing cluster, you gain access to better resources and support.

Supportive Service Providers

Technical consulting firms

You can ask technical consulting firms for advice. These experts help you solve problems with your machines or improve your production process. They offer training and suggest new ways to save energy. You can trust their knowledge to help you stay ahead in the plastic extrusion industry.

Logistics and distribution companies

You also rely on logistics and distribution companies. These businesses move your finished products to customers across China and around the world. They plan the best routes and handle customs paperwork. You can focus on production while they take care of shipping. This support helps you reach more customers and grow your market.

Government Support for Plastic Extrusion

You see strong government support when you work in plastic extrusion in China. This support helps you grow your business and reach new markets. You benefit from policies, infrastructure, and regulations that make your work easier and more efficient.

Favorable Policies and Incentives

Tax incentives for manufacturers

You enjoy tax incentives that lower your costs. The government gives you tax breaks when you invest in new equipment or expand your factory. You save money and can use these funds to improve your production lines. Many manufacturers use these incentives to buy better machines and train workers.

Export subsidies

You also receive export subsidies when you sell products overseas. The government helps you pay for shipping and marketing. You can offer competitive prices to buyers in other countries. These subsidies make it easier for you to enter global markets and grow your business.

Tip: Use government incentives to upgrade your technology and reach more customers.

Infrastructure Development

Modern transportation networks

You rely on modern transportation networks to move your goods quickly. High-speed trains, highways, and ports connect your factory to suppliers and customers. You ship raw materials and finished products without delays. This network helps you keep your promises to buyers and avoid costly setbacks.

Industrial parks and zones

You may set up your factory in an industrial park or zone. These areas offer shared services, reliable utilities, and easy access to suppliers. You find it easier to start your business and expand operations. Many parks provide security and maintenance, so you can focus on production.

- Here is a table showing the benefits of industrial parks:

| Benefit | How You Gain |

|---|---|

| Shared utilities | Lower costs |

| Easy supplier access | Faster production |

| Security services | Safer work environment |

Regulatory Environment

Streamlined business registration

You register your business faster because the government has simplified the process. You fill out fewer forms and wait less time for approval. This streamlined system helps you start production quickly. You spend less time on paperwork and more time making products.

Environmental standards enforcement

You follow strict environmental standards in your factory. The government checks your operations to make sure you protect the environment. You use cleaner machines and recycle waste. These rules help you build a responsible business and earn trust from customers.

Note: Meeting environmental standards can help you win contracts with buyers who care about sustainability.

You see that government support gives you many advantages in plastic extrusion. You use incentives, infrastructure, and regulations to grow your business and compete globally.

Global Market Reach of China’s Plastic Extrusion

Export-Oriented Production

Competitive pricing for international buyers

You can offer products at prices that attract buyers from around the world. Chinese factories use large-scale production and efficient systems to keep costs low. This advantage lets you compete with companies from other countries. Many international customers choose your products because they get good value for their money.

Compliance with global standards

You meet strict quality and safety standards set by different countries. Your factory follows rules for materials, testing, and labeling. This attention to detail helps you sell products in Europe, North America, and many other regions. When you follow these standards, you build trust with your customers.

Tip: Always check the latest requirements for each market before shipping your products.

International Partnerships and Joint Ventures

Collaboration with foreign companies

You work with companies from other countries to share knowledge and technology. These partnerships help you learn new skills and improve your products. Sometimes, you join with foreign firms to create new types of plastic goods. This teamwork makes your business stronger and more creative.

Participation in global supply chains

You play an important role in supply chains that reach across the world. Many large brands rely on your factory to make parts or finished products. You ship your goods to different countries, where they become part of cars, electronics, or packaging. Your ability to deliver on time helps you keep these important business relationships.

- Here are some benefits of joining global supply chains:

- Access to more customers

- Learning about new markets

- Building a strong reputation

Brand Reputation in Plastic Extrusion

Recognition for quality and reliability

You earn respect from buyers because your products work well and last a long time. Many customers return to you for repeat orders. They know you care about quality and always try to improve. Your reputation grows as more people hear about your reliable service.

Strong presence at international trade shows

You attend trade shows in cities around the world. At these events, you show your latest products and meet new customers. You also see what other companies are doing and learn about new trends. Trade shows help you connect with buyers and partners from many countries.

Note: A strong presence at trade shows can help you find new business opportunities.

You see that your global market reach comes from competitive pricing, strong partnerships, and a trusted brand. These strengths help you succeed in the plastic extrusion industry.

Workforce and Education in Plastic Extrusion

Technical Training Programs

Vocational schools specializing in plastics

You find many vocational schools in China that focus on plastics and extrusion technology. These schools teach you the basics of plastic materials, machine operation, and safety rules. You learn how to use extrusion machines and solve common problems. Teachers show you real-life examples and let you practice with modern equipment. When you finish your training, you feel ready to work in a factory or start your own business.

Tip: If you want to join the plastic extrusion industry, look for a school that offers hands-on training with real machines.

Industry-led certification courses

You can also join certification courses run by industry groups or companies. These courses help you learn new skills or improve what you already know. You study topics like quality control, machine maintenance, and new extrusion methods. After you pass the tests, you get a certificate that shows you have special skills. Many employers look for workers with these certificates because they know you can do the job well.

- Benefits of certification courses:

- You gain up-to-date knowledge.

- You increase your chances of getting a good job.

- You show employers you care about learning.

Talent Development and Collaboration

University-industry partnerships

You see many universities in China working with plastic extrusion companies. These partnerships help you learn about the latest research and technology. Professors and engineers work together to solve real problems in factories. Sometimes, you can join special projects or internships. You get to use new machines and test new materials. This experience helps you understand how science and industry connect.

| University Role | Industry Role |

|---|---|

| Teach new theories | Share real problems |

| Offer lab resources | Provide equipment |

| Guide student projects | Hire skilled graduates |

Continuous professional development

You need to keep learning if you want to stay ahead in plastic extrusion. Many companies offer training classes for workers. You can attend workshops, watch online videos, or join study groups. You learn about new machines, better ways to save energy, and how to make safer products. When you keep learning, you help your company grow and improve your own skills.

Note: Lifelong learning helps you adapt to changes in the industry and keeps your job skills strong.

You see that strong education and training programs help you succeed in China’s plastic extrusion industry. When you learn new skills and work with others, you build a bright future for yourself and your company.

Adaptability and Innovation in Plastic Extrusion

Fast Response to Market Changes

Flexible production lines

You see that factories in China change their production lines quickly. Managers use machines that adjust to different shapes and sizes of plastic products. You can switch from making pipes to sheets in a short time. This flexibility helps you meet new orders without long delays. When a customer asks for a special product, you do not need to build a new line. You just change the settings on your machines.

- Benefits of flexible production lines:

- You save time when switching products.

- You reduce waste because you use machines more efficiently.

- You respond faster to market trends.

Tip: If you want to stay ahead, learn how to operate machines that handle many types of plastics.

Customization for client needs

You notice that customers often want products with special features. Factories in China offer many choices for color, size, and shape. You work with engineers to design products that fit each client’s needs. When a buyer requests a new type of packaging, you test different materials and shapes. You use computer software to create samples before starting full production.

| Customization Option | How You Benefit |

|---|---|

| Color | Match client branding |

| Size | Fit specific uses |

| Shape | Unique product design |

You help your clients stand out in their markets. Customization builds strong relationships and brings repeat business.

Entrepreneurial Culture

Support for startups and SMEs

You see many new companies starting in the plastic extrusion industry. The government and local groups offer help to small businesses. You can get advice, training, and even funding. If you have a new idea, you find support to test it. Startups often work with larger factories to share resources. You learn from others and grow your business step by step.

- Ways you get support:

- Attend workshops for new entrepreneurs.

- Join business incubators that offer space and tools.

- Apply for grants to develop new products.

Note: Small businesses often bring fresh ideas to the industry.

Encouragement of new business models

You notice that companies in China try new ways to sell and deliver plastic products. Some use online platforms to reach more customers. Others offer subscription services for regular orders. You see businesses that focus on eco-friendly plastics or smart packaging. When you try a new business model, you test what works best for your market.

| Business Model | Example |

|---|---|

| Online sales | Sell products on e-shops |

| Subscription service | Monthly deliveries |

| Eco-friendly products | Use recycled plastics |

You find that innovation helps you grow and compete. When you explore new ideas, you discover better ways to serve your clients.

Tip: Stay curious and open to change. New business models can help you reach more customers and improve your products.

You see China’s success in plastic extrusion because many strengths work together. You benefit from low costs, advanced technology, and strong support from the government. Skilled workers and a rich industrial ecosystem help you grow your business. You reach global markets and adapt quickly to new trends. These factors make China a leader and help you set the pace in the industry.

FAQ

What is plastic extrusion?

Plastic extrusion is a process where you melt plastic and push it through a shaped die. You create products like pipes, sheets, and films. Factories use special machines to control the shape and size.

Why does China lead in plastic extrusion?

You see China lead because factories use advanced machines and skilled workers. The country has strong support from the government and easy access to raw materials. You benefit from low costs and fast production.

How do Chinese factories keep costs low?

Factories buy materials in bulk and use efficient machines. You find skilled workers who work quickly. Large production volumes help you lower the cost for each product.

Tip: High productivity and smart logistics also help you save money.

What products can you make with plastic extrusion?

You can make pipes, window frames, packaging films, cables, and building materials. Factories also produce custom shapes for electronics and automotive parts.

| Product Type | Example Use |

|---|---|

| Pipe | Water supply |

| Film | Food packaging |

| Cable insulation | Electronics |

How do you ensure quality in plastic extrusion?

You test materials before production. You use machines that measure and control temperature and pressure. Workers check finished products for defects. You follow strict standards for safety and quality.

Can you customize plastic extrusion products?

Yes, you can choose color, size, and shape. Factories use flexible machines and computer software to design products for your needs. You work with engineers to create samples and test new ideas.

What skills do you need to work in plastic extrusion?

You need to understand machine operation and safety rules. You learn about plastic materials and quality control. Training programs and certification courses help you gain these skills.

Note: Continuous learning helps you keep up with new technology.

Post time: Sep-01-2025