The type of blowing screw barrel I choose significantly impacts blow molding processes, particularly when using a PC blowing bottle machine. A well-selected blow molding screw barrel enhances production efficiency while minimizing scrap rates. Aligning my choice with specific manufacturing needs ensures optimal performance, especially when operating machines like the Injection Stretch Blow Molding Machine.

Overview of Blowing Screw Barrels

Definition and Function

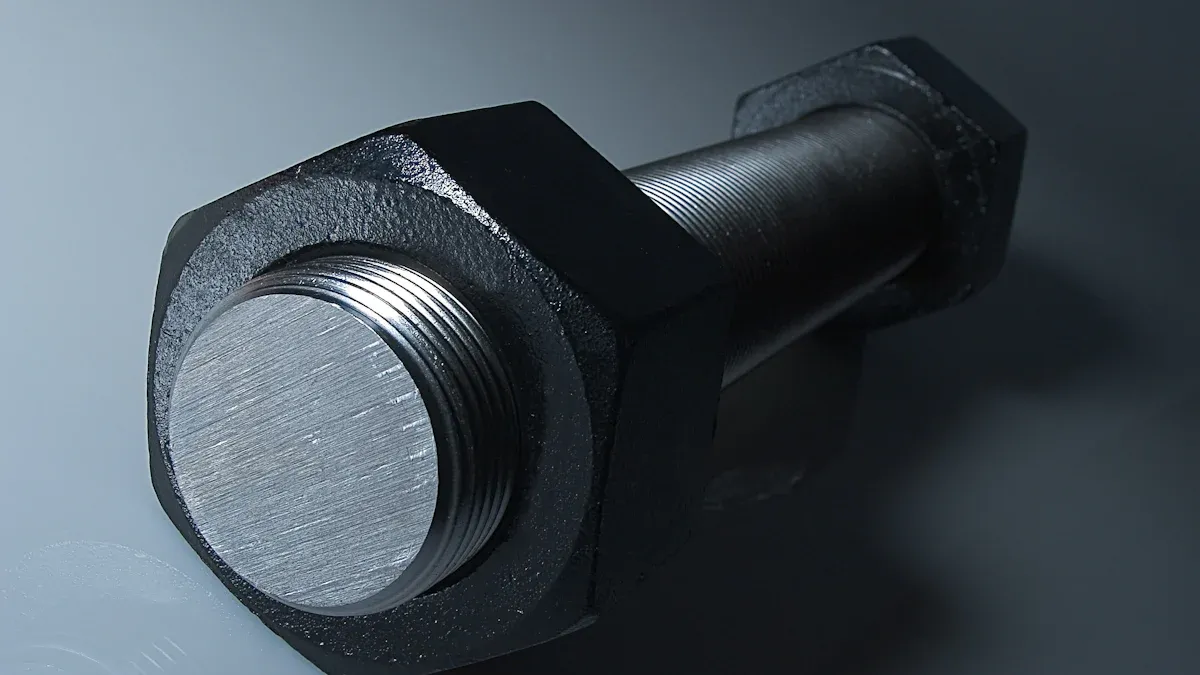

A blowing screw barrel is a critical component in the blow molding process. It serves as the conduit through which raw materials, typically thermoplastics, are transformed into usable products. The design of the screw barrel directly influences the shear on the material, which affects the melt temperature. This relationship is vital for achieving optimal parison formation and minimizing cycle times. I have found that using a screw specifically designed for the material, such as HDPE or PP, significantly enhances output and efficiency. A general-purpose screw may compromise performance, leading to inefficiencies.

Role in Blow Molding

In blow molding, the blowing screw barrel plays a pivotal role in ensuring material homogeneity. The following features contribute to this essential aspect:

| Feature | Contribution to Material Homogeneity |

|---|---|

| Consistent Material Flow | Essential for producing high-quality bottles with uniform parisons. |

| Improved Melt Homogeneity | Achieved through helical grooves and barrier screws, ensuring even melting. |

| Customization of Designs | Tailored to specific resins, reducing scrap and improving part quality. |

| Temperature Control | Maintains proper material flow, preventing uneven melting and degradation. |

Current trends in screw barrel technology, such as the development of bimetallic barrels, enhance durability and performance. These advancements, along with improved heating and cooling systems, contribute to better temperature control during processing. I have noticed that these innovations lead to reduced operational costs and improved product quality, making the right choice of blowing screw barrel even more crucial.

Types of Blowing Screw Barrels

Single-Screw Barrels

Single-screw barrels are among the most common types used in blow molding. I appreciate their simplicity and effectiveness in melting and mixing raw materials. These barrels ensure a steady movement of the plastic melt during production, which is crucial for maintaining pressure and flow. I have observed that they are particularly effective in various industries, including:

| Industry | Application Description |

|---|---|

| Plastics Industry | Extrusion and injection molding for pipes, sheets, and profiles. |

| Packaging Industry | Film, sheet, and blow molding applications. |

| Automotive Industry | Manufacturing of plastic components and interior parts. |

| Construction Industry | Extrusion of PVC pipes, window profiles, and insulation sheets. |

| Recycling Industry | Processing of plastic waste into reusable granules. |

The single-screw barrel’s design allows for efficient melting, which is essential for producing high-quality blow-molded products. I find that they are particularly effective when working with materials like HDPE and PP, as they provide the necessary control over the melt flow.

Twin-Screw Barrels

Twin-screw barrels offer significant advantages over single-screw designs, especially in terms of mixing and material processing. I have experienced firsthand how their intermeshing screws create a self-wiping action, which enhances mixing efficiency. This feature ensures thorough dispersion of additives and colors, leading to uniform product quality.

| Feature | Twin-Screw Extruder | Single-Screw Extruder |

|---|---|---|

| Mixing Efficiency | Superior mixing ability due to meshing and rotation | Inferior mixing ability |

| Material Stability | Maintains stability and uniformity during processing | Less stable during processing |

| Extrusion Speed | Faster extrusion speed | Slower extrusion speed |

| Energy Consumption | Lower energy consumption per unit output | Higher energy consumption |

In high-output blow molding operations, twin-screw barrels excel due to their enhanced mixing capabilities and higher throughput. I have found that they can handle diverse materials, including high-viscosity polymers and heat-sensitive compounds, making them versatile for various applications.

Barrier-Screw Barrels

Barrier-screw barrels play a crucial role in controlling melt flow and pressure during blow molding. Their design features parallel channels that facilitate the gradual conversion of solid pellets into melt. This design improves energy efficiency and ensures better control over melt flow, which is vital for producing high-quality products.

The benefits of using barrier-screw barrels include:

- Enhanced melting and mixing efficiency.

- Improved temperature control, which prevents degradation of sensitive materials.

- Reduced drag flow, leading to better melt quality.

I have noticed that these barrels significantly impact the quality of finished blow-molded products. They help maintain consistent melt viscosity, which is essential for achieving uniform wall thickness and overall product integrity.

Mixing-Screw Barrels

Mixing-screw barrels are designed to enhance color and additive dispersion in blow molding. I often use barrier and Maddock designs, as they ensure better melt uniformity and prevent unmelted bits from clogging the system. This capability leads to fewer defects and improved color consistency in the final products.

The advantages of mixing-screw barrels include:

- Improved melting efficiency, reducing thermal degradation.

- Enhanced mixing quality, leading to better homogenization of polymer blends.

- Better control over pressure and flow, ensuring dimensional accuracy.

I find that these barrels are particularly beneficial when working with complex polymer blends, as they provide the necessary versatility and efficiency for high-quality production.

Choosing the Right Blowing Screw Barrel

Factors to Consider

When selecting a blowing screw barrel, I consider several critical factors to ensure optimal performance. Each polymer type has unique requirements that influence my choice. Here are some key considerations:

- Material Compatibility: Different polymers require specific screw designs. For instance, when working with PMMA, I opt for a gradual screw with a length-to-diameter ratio of 20-22 and a compression ratio of 2.3 to 2.6. For PET, I prefer a low shear screw with a compression ratio of 1.8-2, avoiding a mixing zone at the front end. PVC demands a low shear design with corrosion-proof materials and a length-to-diameter ratio of 16-20.

- Screw Geometry: The geometry of the screw barrel significantly affects processing. I often refer to the following table to guide my decisions:

| Screw Type | L/D Ratio | Application Description |

|---|---|---|

| General Purpose | ~20:1 | Suitable for common plastics but may show color variation. |

| Barrier Screws | ~24:1 | Improves mixing for reinforced plastics. |

| Separation Screws | ~18:1 | Helps heat-sensitive materials avoid degradation. |

| Mixing Screws | ~22:1 | Provides uniform melt for specialty plastics. |

- Environmental Conditions: I also pay attention to the temperature and humidity of the machine room. Maintaining a stable environment helps prevent equipment malfunctions. I ensure the temperature stays between 25℃ – 30℃ and humidity at 40% – 60%.

Impact on Production Efficiency

The right blowing screw barrel can significantly enhance production efficiency. I have observed that a well-designed screw optimizes cycle time by aligning with the processor’s goals. Here are some factors that influence efficiency:

- Screw Geometry: This is the most significant parameter affecting throughput and pressure development. A proper design can lead to faster production rates.

- Heat Profiles: I find that proper heat profiles based on screw design enhance energy efficiency, indirectly affecting cycle time. Improved screw design contributes to sustainability while addressing cycle time targets.

- Compression Zone: The compression zone plays a crucial role in throughput, especially at higher screw rotation frequencies. I ensure that the design aligns with my production needs to maximize output.

Influence on Product Quality

The choice of blowing screw barrel directly impacts the quality of the final product. I focus on several aspects to ensure high-quality outcomes:

- Melt Quality: A well-designed screw barrel maintains consistent melt viscosity, which is essential for achieving uniform wall thickness. This consistency leads to better product integrity.

- Energy Consumption: The efficiency of the screw and barrel system is crucial for energy consumption. I have learned that wear and tear can lead to inefficiencies, increasing energy consumption as the gap between the screw and barrel widens. This affects melt quality and requires more energy to maintain production.

- Testing Procedures: I regularly conduct inspections and monitor critical process parameters such as pressure, temperature, and screw speed. This proactive approach helps me identify issues early and maintain product quality.

By carefully considering these factors, I can select the right blowing screw barrel that aligns with my production goals and ensures high-quality output.

Selecting the right screw barrel type is crucial for optimizing blow molding processes. I encourage you to assess your specific production needs before making a decision.

The price paid for this component is just the beginning. The working life of a barrel can be disastrously short, depending on how it was manufactured and used.

Informed selection leads to reduced maintenance and downtime, ensuring long-term cost benefits for your operations.

FAQ

What factors influence the choice of a blowing screw barrel?

I consider material compatibility, screw geometry, and environmental conditions when selecting a blowing screw barrel.

How does the screw barrel affect production efficiency?

A well-designed screw barrel optimizes cycle time, enhances throughput, and improves energy efficiency, leading to increased production rates.

Can the type of screw barrel impact product quality?

Yes, the right screw barrel maintains consistent melt viscosity, ensuring uniform wall thickness and overall product integrity.

Post time: Sep-17-2025