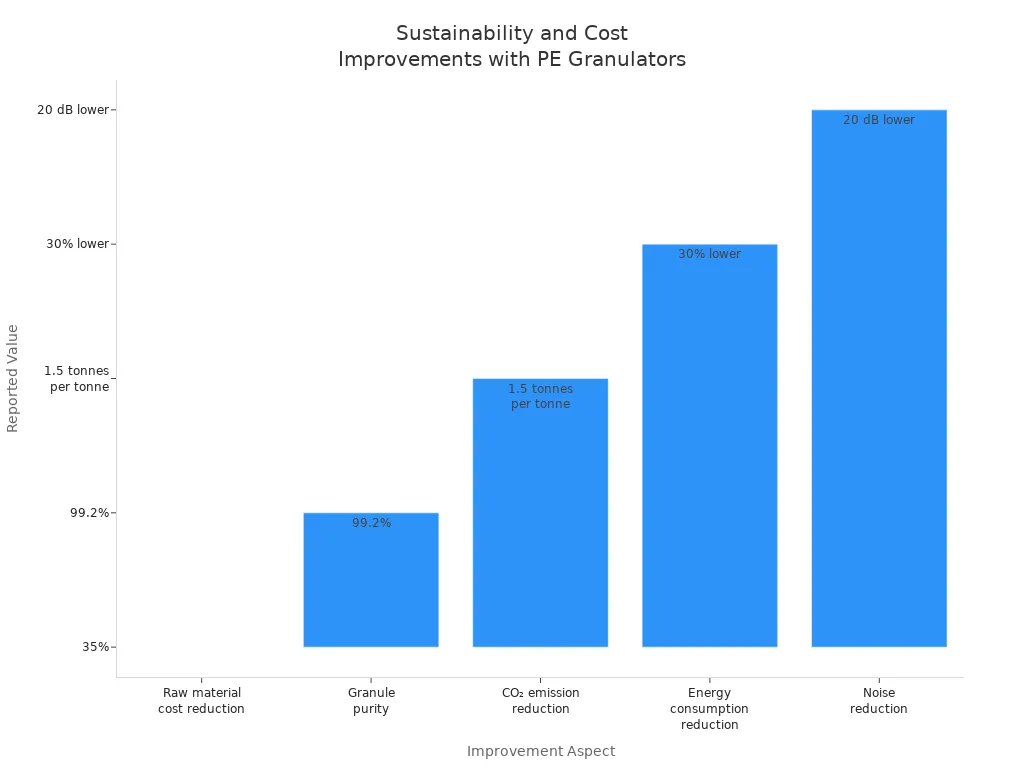

PE small environmentally granulators help manufacturers cut energy use with smart features and new technology. The latest models show impressive results:

| Metric | 2025 Reduction vs. Previous Years |

|---|---|

| Energy Consumption (kW-h/tonne) | 40% lower |

| Greenhouse Gas Emissions | 33% less |

| Fossil Fuel Usage | 45% less |

They use high-efficiency motors, waste heat recovery, and air-cooled systems. An Environment Mini-Pelletizer Machine and Waterless Granulator Machine can handle Pvc Pelletizing Extrusion efficiently.

Energy-Saving Features of PE Small Environmentally Granulators

High-Efficiency Motor Systems

PE small environmentally granulators in 2025 use advanced motor technology to save energy and boost performance. These machines rely on electric drive devices with motor power ranging from 22 kW to 110 kW, depending on the model size. The motors work with capacities from 200 to 1200 kg/h, making them perfect for small and medium recycling operations. The table below shows some key technical details:

| Specification | Details |

|---|---|

| Motor Power Range | 22 kW to 110 kW |

| Drive Type | Electric drive devices |

| Auxiliary Drive Power | 1.1 kW |

| Capacity Range | 200-1200 kg/h |

| Application | PE and other plastic granulation |

These high-efficiency motors use servo drives and intelligent controls. They help operators save up to 40% more energy compared to older motors. Real-time monitoring and automation keep the system running smoothly, reducing downtime and cutting electricity costs.

Optimized Blade and Transmission Design

The blade and transmission system in PE small environmentally granulators plays a huge role in energy savings. Manufacturers use custom blades made from premium alloys like tungsten carbide or high-speed steel. These materials last longer and cut more efficiently. Here are some ways optimized blades help:

- Precision blade angles reduce motor load and power use.

- Advanced coatings, such as titanium nitride, lower friction by up to 40%.

- Regular ultrasonic cleaning keeps blades sharp and prevents residue buildup.

- Flat blades work best for soft plastics, lowering resistance and saving energy.

- High-hardness materials increase production capacity by up to 30%.

A German recycling plant saw a 22% jump in efficiency and a 14% drop in energy use per ton after switching to better blade materials. When blades stay sharp and clean, the whole machine runs better and uses less power.

Smart Automation and Process Control

Smart automation makes PE small environmentally granulators even more efficient. These machines use PLC control systems and touch screens for easy operation. Automation features include:

- Auto feeding control for steady material flow.

- Dual channel filter systems that let operators change screens without stopping.

- Back-flush filter systems for automatic waste discharge.

- Auto-adjustment of pelletizing knife speed and pressure for uniform pellets.

- Online troubleshooting and parameter optimization through cloud control.

Tip: Smart automation not only saves energy but also reduces the need for manual labor. Operators can focus on other tasks while the machine handles routine adjustments.

Integrated designs combine shredders, compactors, and extruders into one system. This setup keeps the process running without long breaks, which means less wasted energy and higher output.

Waste Heat Recovery and Utilization

PE small environmentally granulators do not let valuable heat go to waste. During operation, these machines generate heat. Instead of losing it, the system captures and recycles this heat for other production steps, such as pre-heating materials or warming the workspace. This approach lowers the need for extra heating equipment and cuts overall energy use.

- Waste heat recovery supports environmental goals by reducing greenhouse gas emissions.

- Reusing heat helps manufacturers meet strict energy and environmental standards.

- The process also keeps operating costs down, making the granulators a smart investment.

By combining these energy-saving features, PE small environmentally granulators set a new standard for efficiency and sustainability in plastic recycling.

Practical Benefits and Environmental Impact

Lower Operational Energy Consumption

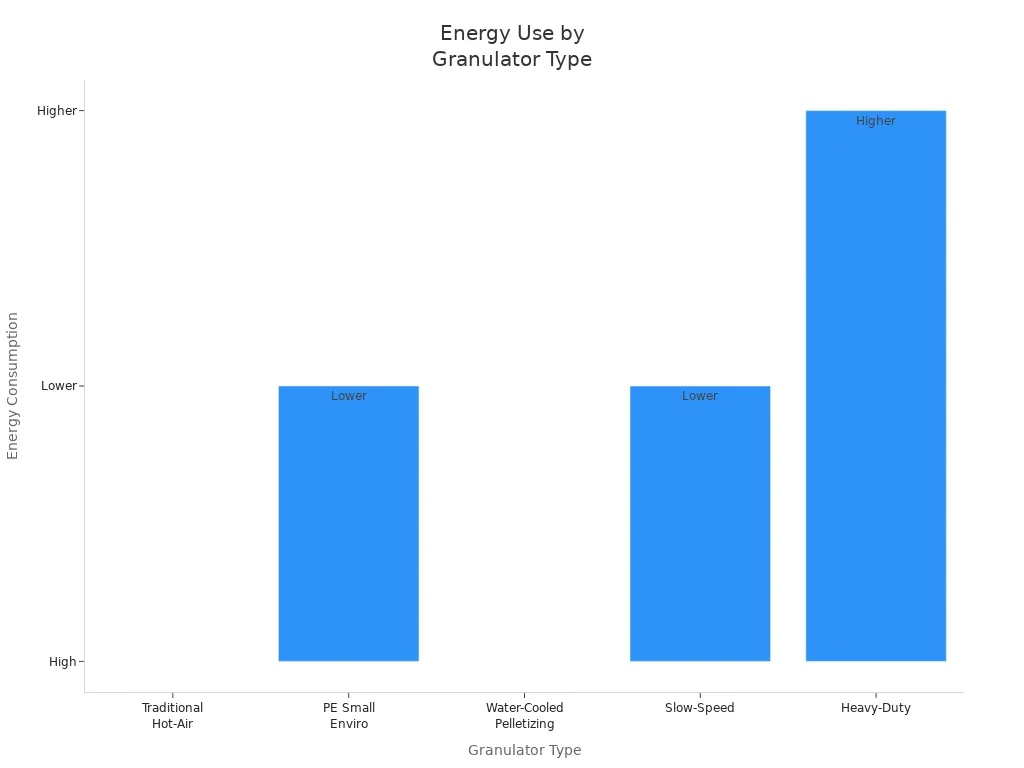

PE small environmentally granulators stand out for their low energy use. Many traditional granulators, like hot-air or water-cooled systems, consume more electricity and create more pollution. The table below shows how different granulator types compare:

| Granulator Type | Energy Consumption | Environmental Impact | Operational Notes |

|---|---|---|---|

| Traditional Hot-Air Plastic Granulators | High | Significant pollution | Over 75% of equipment; needs upgrades |

| PE Small Environmentally Friendly Granulators | Lower due to air cooling and low-temp operation | Reduced emissions due to energy savings | Uses renewable resources and waste heat recovery |

| Water-Cooled Pelletizing Systems | High (water and electricity) | Environmental burden from water use | Large footprint, complex operation |

| Slow-Speed Granulators | Lower | Lower noise and wear | Good for small parts, beside-the-press use |

| Heavy-Duty Granulators | Higher | Higher due to throughput | For tough materials; less energy efficient |

Air-cooled, low-temperature operation helps these granulators use less energy. They also skip the drying step, which saves even more power.

Reduced Carbon Footprint and Compliance

These machines help companies shrink their carbon footprint. They use less power and recycle plastic waste on-site, which means fewer trucks on the road and less pollution. Small plastic recycling machines also keep waste out of landfills. By turning old plastic into new pellets, they cut down on the need for new raw materials. Many companies now meet strict environmental rules thanks to these upgrades.

Note: A German car maker saved 300 tonnes of new plastic each year by recycling bumper waste with small granulators.

Cost Savings and Production Efficiency

Manufacturers see real savings with these granulators. High-efficiency motors and smart automation lower electricity bills. Less manual work means fewer mistakes and less downtime. The table below shows how a structured approach boosts efficiency and profits:

| Stage | Description | Key Actions |

|---|---|---|

| Planning | Define objectives and KPIs | Set SMART goals, allocate resources |

| Execution | Implement changes in controlled env | Pilot projects, standardize training |

| Evaluation | Monitor progress and gather feedback | Use data analytics, adjust as needed |

| Expansion | Scale successful practices | Integrate lessons learned, train |

A 20% drop in cycle time can lead to more revenue. Waste heat recovery and lower energy use also cut costs.

Compact Size and Space Efficiency

The compact design of these granulators saves valuable floor space. Smaller workshops and recycling centers can fit them in without changing their layout. Operators find them easy to maintain and clean, which means less downtime. The modular setup supports closed-loop recycling, making the whole process more efficient and sustainable.

Tip: A smaller footprint means more room for other equipment or future expansion.

PE small environmentally granulators set a new standard for energy efficiency in 2025. Manufacturers see real benefits:

- Lower costs and less waste

- Higher recycling rates

- Support for sustainability goals

- Fast payback and strong compliance

FAQ

How does the PE small environmentally granulator help save energy?

The granulator uses high-efficiency motors and smart automation. These features cut electricity use and keep production steady.

Tip: Smart controls let operators adjust settings quickly for even more savings.

Can small workshops use this granulator?

Yes, they can. The compact size fits tight spaces. Operators find it easy to install and maintain.

- Fits small production lines

- Simple to operate

What materials can the PE small environmentally granulator process?

It handles PE and other plastics. The machine works well for recycling plastic waste into new pellets.

| Material Type | Suitable for Granulation? |

|---|---|

| PE | ✅ |

| PP | ✅ |

| PVC | ✅ |

Post time: Aug-14-2025