A Conical Twin Screw Barrel features a tapered design that enhances material mixing and conveying efficiency. In plastic extrusion, the Conical twin screw extruder PVC system ensures optimal melting and processing of PVC materials. Leading manufacturers, including the Conical Twin Screw Extruder Barrels Factory, utilize advanced modeling techniques and precise tapered twin screw barrel and screw parameters to maximize performance.

| Market Size 2024 | Projected 2033 | CAGR (2025-2033) |

|---|---|---|

| USD 1.2 billion | USD 2.5 billion | 8.9% |

Engineers depend on the right tapered twin screw barrel and screw to achieve consistent and high-quality extrusion results.

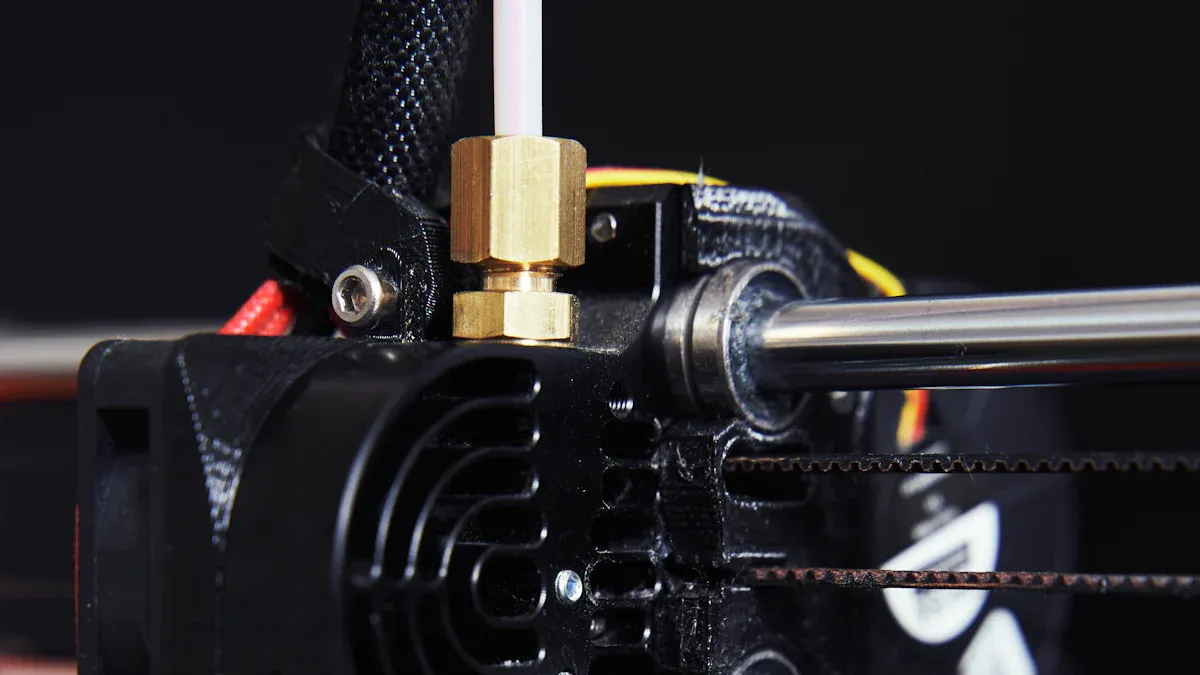

Conical Twin Screw Barrel Components and Design

Structure and Tapered Geometry

The structure of a Conical Twin Screw Barrel stands out because of its unique tapered geometry. This design features a gradual decrease in screw diameter from the feed zone to the discharge zone. The tapering creates a dynamic and uniform shear force distribution. This helps improve mixing and ensures that materials blend evenly. The geometry also reduces the volume inside the barrel as materials move forward. This change optimizes material conveying and minimizes the risk of blockages.

The tapered design lowers resistance and power consumption, which increases energy efficiency. It also promotes even heat distribution. This prevents hotspots and improves thermal management. The geometry induces complex flow patterns that enhance mixing efficiency. As a result, the process does not need excessive shear or extra energy input. The controlled reduction in diameter allows for precise control over how long materials stay in the barrel. This leads to efficient processing and better material properties.

Other important design features include:

- Increased length-to-diameter ratio, which extends the processing path and allows more time for material transformation.

- Multiple temperature zones, each independently controlled, for precise thermal management.

- Reduced shear stress, which protects heat-sensitive materials and improves process predictability.

- Versatility in processing different materials, thanks to the adaptable tapered design.

Key Materials Used

Manufacturers select materials for Conical Twin Screw Barrel components based on durability and performance. The barrel and screws often use high-strength alloy steels. These materials resist wear and corrosion, which is important for long-term operation. Some barrels receive special surface treatments or coatings. These treatments further increase resistance to abrasion and chemical attack.

Common materials include:

- Nitrided steel, which offers excellent surface hardness.

- Bimetallic alloys, which provide extra protection in high-wear environments.

- Stainless steel, which resists corrosion when processing aggressive or reactive compounds.

The choice of material depends on the type of polymer or compound being processed. For example, barrels used for PVC extrusion often require materials that can withstand the corrosive nature of chlorine-based compounds. This careful selection ensures that the Conical Twin Screw Barrel maintains high performance and a long service life.

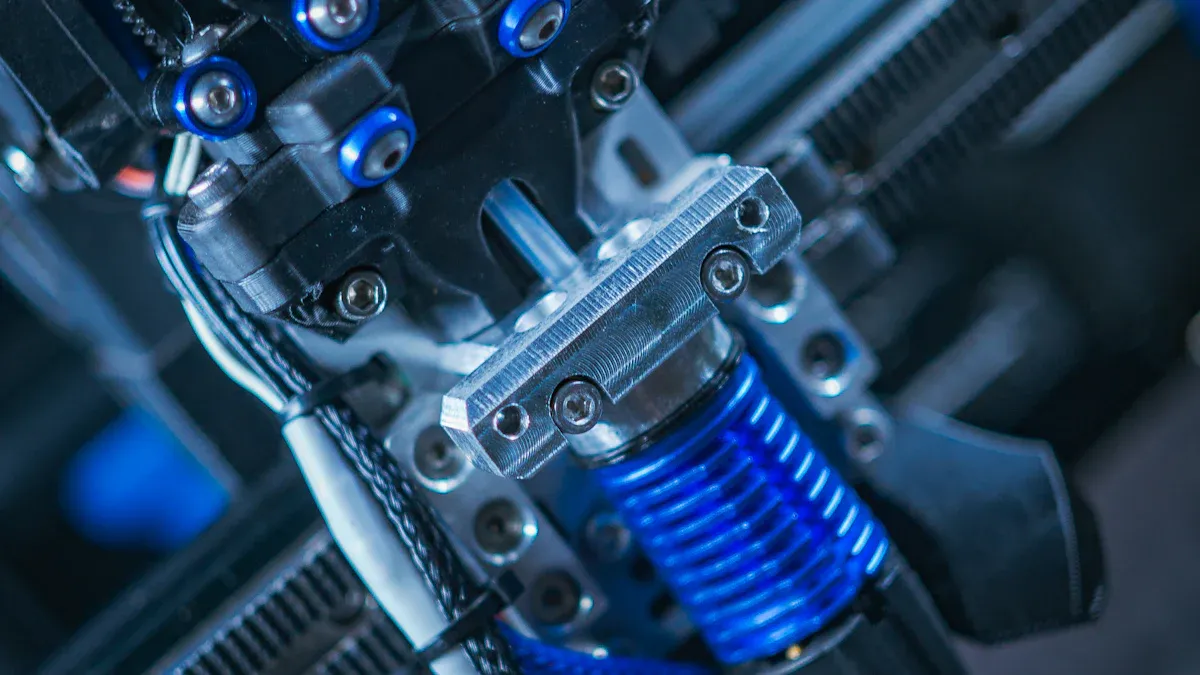

Screw Types and Their Roles

The screw is a critical part of the Conical Twin Screw Barrel. Different screw elements perform specific functions during the extrusion process. Engineers design these elements to optimize mixing, melting, and conveying.

| Screw Element Type | Quantitative Parameter Measured | Role in Mixing / Effect on Process |

|---|---|---|

| Single Lead Elements | Residence Time Distribution | Influence axial mixing and flow characteristics |

| Mixing Paddles | Viscous Dissipation, RTD | Enhance dispersive and distributive mixing by increasing shear and elongational forces |

| Reversed Pitch Elements | Curve Spread, Stagnancy | Modify flow patterns to reduce stagnancy and improve distributive mixing |

Single lead elements control how long materials stay in the barrel and help move them forward. Mixing paddles increase shear and stretching forces, which break up and blend materials more thoroughly. Reversed pitch elements change the direction of flow. This reduces areas where material might stagnate and improves overall mixing.

Engineers can adjust the configuration of these screw elements to match the needs of different materials and processes. This flexibility makes the Conical Twin Screw Barrel suitable for a wide range of extrusion applications.

How Conical Twin Screw Barrel Works in Plastic Extrusion

Operational Principles

A Conical Twin Screw Barrel operates with a focus on flexibility and efficiency. Engineers design these systems to handle a wide range of plastic extrusion requirements. The conical geometry produces high torque while maintaining gentle plasticization. This feature is essential for processing materials that are sensitive to heat and shear. The screws have a high surface area and low shear profile, which allows efficient heat transfer during extrusion.

Manufacturers often apply proprietary coatings, such as nitride or tungsten, to the screws and barrels. These coatings increase wear resistance and improve heat transfer. The modular design and customizable screw configurations help optimize the extrusion process for different applications. High-quality DIN steel forms the base material, with options for chrome plating or carbide encapsulation for demanding uses.

Operators monitor several parameters during extrusion:

- Temperature

- Melt pressure

- Torque

- Screw speed

- Feed rate

These measurements reflect how the material behaves inside the barrel and confirm the system’s operational effectiveness.

Melting, Mixing, and Conveying Process

The melting, mixing, and conveying mechanisms rely on precise control of process parameters and screw design. The following table shows how each parameter or design element validates these mechanisms:

| Process Parameter / Design Element | Role in Validating Mechanism |

|---|---|

| Screw Speed (rpm) | Controls shear rate, influences melting and mixing intensity |

| Feed Rate | Affects residence time and melting efficiency |

| Torque | Indicates mechanical load and energy input for melting and conveying |

| Pressure | Reflects material flow resistance and conveying efficiency |

| Temperature | Monitors melting state and thermal conditions |

| Residence Time Distribution (RTD) | Validates mixing uniformity and exposure time to shear and heat |

| Screw Geometry | Determines conveying speed, shear intensity, and mixing type |

| Mixing Elements | Facilitate distributive and dispersive mixing, affecting melt homogeneity |

Operators adjust these parameters to achieve uniform melting, thorough mixing, and efficient material transport. The design of the Conical Twin Screw Barrel ensures that each stage of the process supports high-quality extrusion results.

Conical Twin Screw Barrel vs. Other Types

Conical vs. Parallel Twin Screw Barrels

Conical and parallel twin screw barrels serve similar roles in plastic extrusion, but their designs create different processing advantages. The conical design uses tapered screws, which create a smaller gap as material moves forward. This feature increases material compression and improves degassing. It also allows for higher torque transmission, making it ideal for materials with low bulk density or those that trap gas. Parallel twin screw barrels, on the other hand, use screws with a constant diameter. These systems excel in mixing and compounding, especially when the screws rotate in the same direction. Parallel designs promote self-cleaning and uniform dispersion. Mathematical models show that conical twin screw barrels improve intake volume and pressure generation, which leads to better extrusion efficiency compared to parallel designs.

- Conical barrels: Better for compression, degassing, and torque.

- Parallel barrels: Better for mixing, compounding, and self-cleaning.

Unique Benefits of Conical Design

The conical design offers several unique benefits. It enhances output and productivity, especially in PVC pipe manufacturing. The gradual reduction in screw channel volume increases pressure and improves compounding. This design also supports gentle shearing, which protects heat-sensitive materials. Operators can adjust screw speed and diameter to optimize output rates and melt quality. The conical twin screw barrel improves mixing, resulting in uniform color and better mechanical properties in finished products. Advanced control systems further boost process efficiency and product consistency.

The conical design also helps reduce energy consumption and waste, supporting cost-effective and sustainable production.

Typical Applications

The Conical Twin Screw Barrel finds use in many industries. It processes PVC pipes, profiles, and sheets with high efficiency. Manufacturers use it for hard-to-recycle plastics and medical-grade polymers. The design supports high output rates, with profiles reaching up to 550 lb/hr and pipes up to 1000 lb/hr. It also improves product quality by reducing pinholes and ensuring uniform moisture content. Industries such as pharmaceuticals, plastics, and composites benefit from its modular design and adaptability.

| Application Area | Benefit Provided |

|---|---|

| PVC Pipe Manufacturing | High output, uniform melt, stable quality |

| Profile Extrusion | Enhanced mixing, precise dimensions |

| Medical Polymers | Gentle processing, consistent properties |

| Recycled Plastics | Versatile material handling, cost savings |

Selecting a Conical Twin Screw Barrel

Material Compatibility

Selecting the right Conical Twin Screw Barrel starts with understanding material compatibility. Engineers must match the barrel and screw design to the specific properties of the material being processed. For example, PVC compounds require a different screw configuration than polyolefins or engineering plastics. Numerical studies help engineers simulate how different screw designs and barrel setups affect material flow, melting, and mixing. These simulations show how screw geometry and process parameters—such as temperature, screw speed, and feed rate—impact the material’s behavior inside the barrel.

When processing sensitive materials, engineers must control shear and heat to prevent degradation. They adjust screw element placement and barrel length to ensure even mixing and melting. Abrasive or corrosive materials need specialized barrel linings or screw coatings to avoid damage. By carefully selecting the right combination of screw and barrel, operators maintain material integrity and achieve consistent product quality.

Tip: Always review the material’s melting point, viscosity, and chemical reactivity before choosing a barrel and screw configuration.

Wear Resistance and Durability

Durability plays a key role in the performance and lifespan of a twin screw barrel. Manufacturers use high-strength alloy steels, nitrided surfaces, and bimetallic linings to resist wear and corrosion. These materials protect the barrel and screws from abrasion caused by fillers, glass fibers, or mineral additives. For highly abrasive or corrosive applications, engineers may specify additional surface treatments or coatings.

A table below summarizes common material choices and their benefits:

| Material Type | Benefit Provided | Typical Application |

|---|---|---|

| Nitrided Steel | High surface hardness | Standard polymer processing |

| Bimetallic Alloy | Superior abrasion resistance | Filled or reinforced plastics |

| Stainless Steel | Corrosion resistance | Reactive or aggressive compounds |

Regular inspection and timely replacement of worn parts help maintain consistent extrusion quality. Choosing the right materials for the barrel and screws reduces downtime and extends equipment life.

Maintenance and Installation Considerations

Proper maintenance and installation ensure reliable operation and long service life for a conical twin screw barrel. Modern extruders, such as the Gemini® Conical Twin Screw Extruders, feature low rpm screws with internal water-cooling systems, robust gearboxes, and efficient air-cooled barrel heaters. These features require careful planning during installation. Operators must provide effective cooling infrastructure, sturdy gearbox support, and adequate feed mechanisms to achieve optimal performance.

Maintenance programs, like those offered by Milacron, include stocking and rebuilding barrels and screws. These services allow operators to extend the life of their equipment and maintain installation integrity. Gearbox rebuilds and upgrades also play a vital role in keeping the extruder stable and reliable.

Note: Schedule regular inspections and keep detailed maintenance records. Quick access to rebuild services and spare parts helps minimize downtime and ensures continuous production.

Impact of Conical Twin Screw Barrel on Extrusion Performance

Efficiency and Output Quality

A Conical Twin Screw Barrel improves extrusion efficiency by optimizing material flow and mixing. The intermeshing screw design and conical shape increase the surface area in the plasticizing section. This design helps distribute heat evenly and reduces energy waste. Operators notice more uniform melt distribution and better temperature control. These features lower the risk of material degradation and improve product consistency.

Production lines using this barrel type often see faster extrusion speeds and higher-quality outputs. Energy consumption can drop by up to 30% compared to traditional barrels. The improved durability of the screws and barrels also means less downtime for maintenance. The table below highlights key performance metrics:

| Metric / Feature | Value / Description |

|---|---|

| Production Efficiency | Greatly improved |

| Energy Consumption | Significant reduction |

| Scrap Rates | Significant reduction |

| Screw Wear Reduction | Up to 60% reduction |

| Throughput Increase | Up to 25% increase |

| Waste Rate | ~1.5% |

| Startup Time for New Dimensions | 1 to 2 hours |

These results show that the Conical Twin Screw Barrel supports stable production, reduces waste, and increases output quality.

Cost-Effectiveness

Manufacturers benefit from the cost-effectiveness of this barrel design. Lower energy use directly reduces operating costs. The strong materials and advanced coatings extend the lifespan of both the barrel and screws. This durability means fewer replacements and less frequent maintenance.

Reduced scrap rates and faster startup times also help save money. Operators spend less time cleaning and adjusting the equipment. The table above shows that waste rates drop to about 1.5%, and startup times for new product dimensions shorten to just 1 to 2 hours. These improvements allow companies to produce more with fewer resources.

Tip: Investing in a Conical Twin Screw Barrel can lead to long-term savings and more reliable production.

A Conical Twin Screw Barrel delivers precise control and high efficiency in plastic extrusion. Studies show optimized extrusion parameters lead to consistent results and improved yields. Users should match barrel design to material needs and monitor process variables. Informed selection ensures reliable performance and superior product quality.

FAQ

What industries use conical twin screw barrels?

Manufacturers in plastics, construction, and medical device industries use conical twin screw barrels for producing pipes, profiles, and specialty polymer products.

How often should operators inspect a conical twin screw barrel?

Operators should inspect the barrel regularly. Most experts recommend monthly checks to ensure optimal performance and prevent unexpected downtime.

Can a conical twin screw barrel process materials other than PVC?

Yes. Conical twin screw barrels handle a variety of polymers, including polyolefins and engineering plastics, by adjusting screw design and process parameters.

Post time: Jul-02-2025