Shear force plays a pivotal role in the operation of the plastic twin screw extruder. It refers to the force that causes layers of material to slide against each other, significantly impacting material properties. For example, higher shear forces enhance mixing and heat distribution. In a Twin Plastic Screw Barrel, the melting zone design ensures efficient material flow while minimizing temperature spikes, as a pressure of 40 bar can elevate temperatures by 20°C. Additionally, a Conical Twin Screw Extruder Screw Barrel further optimizes these processes by balancing shear force and throughput, while the Twin Screw Barrel design contributes to overall efficiency in the extrusion process.

Basics of Plastic Twin Screw Extruder

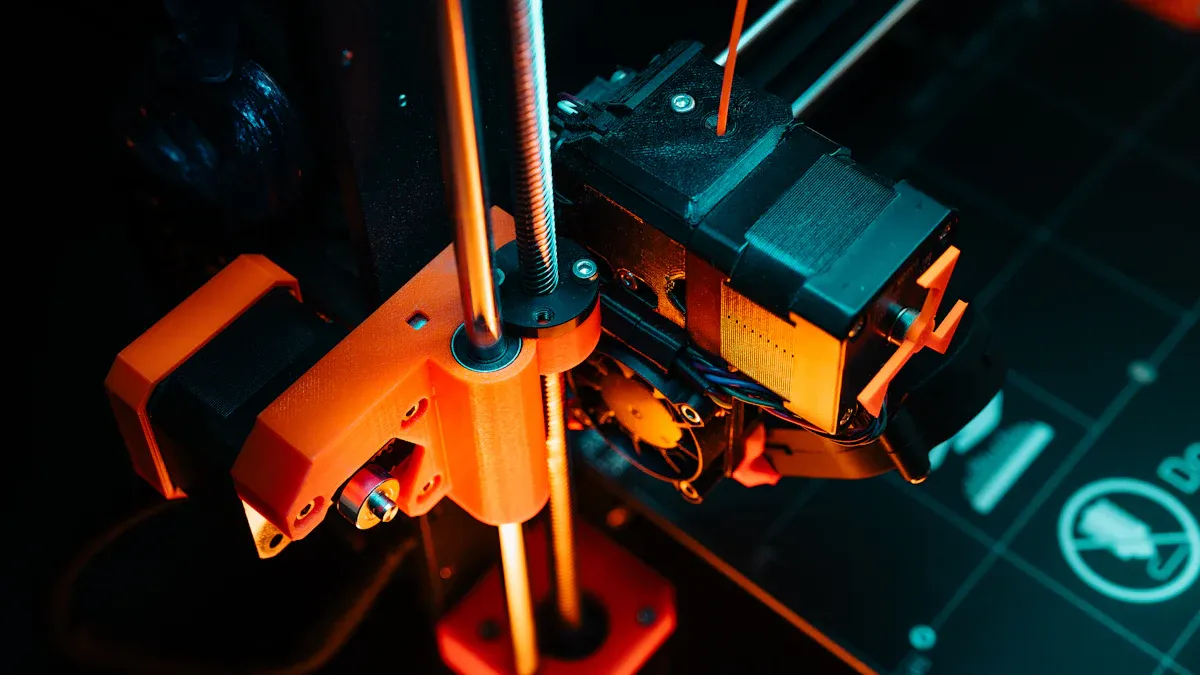

Key Components of the Extruder

A plastic twin screw extruder consists of several critical components that work together to process materials efficiently. These include:

- Hopper: The entry point where raw materials are fed into the system.

- Barrel: The main chamber where materials are melted and mixed.

- Screw Conveyor: Responsible for transporting materials through the extruder.

- Heating System: Provides the necessary heat for melting plastic compounds.

- Temperature Control: Ensures consistent processing conditions.

- Extrusion Head: Shapes the material into the desired form as it exits the extruder.

Each component plays a vital role in ensuring the extruder operates smoothly and delivers high-quality output. For instance, the variable screw speed allows precise control over the extrusion process, while replaceable dies enable the production of various shapes and sizes.

Role of Screws and Barrel in Shear Force Generation

The screws and barrel are central to generating shear force in a plastic twin screw extruder. The screws rotate within the barrel, creating friction and pressure that melt and mix the material. Factors such as screw speed, die diameter, and material behavior significantly influence shear force. For example:

| Parameter | Influence on Shear Force Generation |

|---|---|

| Screw Speed | Higher speeds increase throughput and dissipated power, enhancing shear force. |

| Die Diameter | Larger diameters reduce pressure and power, affecting shear force. |

| Material Behavior | Shear-thinning materials exhibit lower pressure and power compared to Newtonian fluids. |

These interactions ensure efficient material processing and uniform mixing.

Material Flow Dynamics in the Extruder

Material flow dynamics in a plastic twin screw extruder determine the quality of mixing and the final product. Advanced computational methods, such as CFD, have enhanced the understanding of these dynamics. Techniques like the volume-of-fluid (VOF) and level-set methods track fluid interfaces during mixing, ensuring precise control over the process. Twin screw extruders are widely used in industries like pharmaceuticals due to their superior mixing capabilities. Under standard conditions (30 kg/hr, 200 rpm), the pressure in one C-shaped chamber reaches approximately 2.2 MPa, with pressure drops of 0.3 MPa in the intermeshing zone and 0.5 MPa in the reverse screw element. These metrics highlight the efficiency of the extruder in handling diverse materials.

Shear Force Mechanism in Twin Screw Extrusion

Generation of Shear Force in the Extrusion Process

Shear force in a twin screw extrusion process arises from the interaction between the rotating screws and the stationary barrel. As the screws rotate, they create friction and pressure, causing the material to deform and flow. This deformation generates shear forces that play a critical role in melting, mixing, and homogenizing the material. The screws’ intermeshing design ensures that the material experiences consistent shearing throughout the process.

Numerical analysis using the volume-of-fluid (VOF) method has revealed the hydrodynamic mechanisms involved in this process. It highlights how shearing forces, viscosity ratios, and turbulence influence the microstructure of immiscible alloys during mixing. These findings underscore the importance of shear forces in determining the rheological behavior and overall performance of the extrusion process.

Experimental studies further support this mechanism. For instance, research on polypropylene-clay nanocomposites demonstrated that twin screw extruders achieve superior dispersion compared to single screw extruders. This is attributed to the higher shear forces generated in twin screw systems, which enhance the exfoliation of materials and improve their mechanical and thermal properties.

Factors Affecting Shear Force

Several factors influence the generation and magnitude of shear force in a plastic twin screw extruder. These include screw speed, screw geometry, and material viscosity.

- Screw Speed: Increasing the screw speed raises the shear rate, leading to higher shear forces. However, excessive speeds can cause material degradation or overheating.

- Screw Geometry: The design of the screws, including their pitch, flight depth, and intermeshing angle, directly impacts the shearing action. For example, screws with deeper flights generate lower shear forces, while tighter intermeshing angles increase shearing intensity.

- Material Viscosity: High-viscosity materials require greater shear forces to achieve proper mixing and melting. Conversely, low-viscosity materials may flow too easily, reducing the effectiveness of the shearing action.

Statistical studies have analyzed these factors in detail. For instance, research revealed that cumulated strain increases linearly with screw speed but decreases with feed rate. Optimal processing conditions, such as a feed rate of 3.6 kg/h at a screw speed of 95 rpm, maximize temperature while minimizing fiber breakage. These findings highlight the need to balance these factors to achieve efficient extrusion.

Methods for Controlling Shear Force

Controlling shear force is essential for optimizing the extrusion process and ensuring consistent product quality. Several methods can be employed to regulate shear force in a twin screw extruder:

- Adjusting Screw Speed: Operators can increase or decrease the screw speed to modify the shear rate and achieve the desired material properties.

- Customizing Screw Design: Tailoring the screw geometry, such as altering the pitch or flight depth, allows for precise control over the shearing action.

- Using Shear-Thinning Models: These models help predict material behavior under varying shear conditions, enabling better process control. However, relying solely on these models can lead to underestimations of key parameters like pressure and viscosity.

- Implementing Advanced Monitoring Systems: Real-time monitoring of parameters such as temperature, pressure, and torque provides valuable insights into the extrusion process. This data can be used to make adjustments and maintain optimal shear force levels.

Research has shown that the screw’s role in heat transfer is critical for controlling shear force. A recirculation circuit forms within the extruder, which helps distribute heat evenly and prevents localized overheating. This ensures that the polymer melts uniformly, enhancing the overall efficiency of the extrusion process.

Impact of Shear Force on Material Properties

Effects on Mixing and Homogeneity

Shear force plays a critical role in achieving uniform mixing and homogeneity in materials processed by a plastic twin screw extruder. The interaction between screws and the barrel generates friction, which facilitates the blending of polymers and additives. This process ensures that the final product exhibits consistent properties across its structure.

Empirical studies highlight several aspects of shear force impact:

| Aspect of Shear Force Impact | Description |

|---|---|

| Fiber Breakage | Shear forces in the molten matrix lead to fiber breakage, affecting structural properties of the final product. |

| Heat Generation | Approximately 80% of the heat required for melting is generated by friction due to shear between screws and the barrel. |

| Mixing Efficiency | The design of mixing zones with forward- and reverse-conveying elements influences pressure dynamics and overall mixing efficiency. |

| Residence Time Distribution | RTD significantly affects product characteristics by determining exposure time to temperature, pressure, and shear. |

Additionally, increasing rotor speed during polypropylene-sisal melt-mixing results in more fiber breakage, producing smaller fiber lengths. This phenomenon, observed in natural fibers, occurs because shear separates bundled fibers, reducing their diameter. These findings underscore the importance of optimizing shear force to balance mixing efficiency and material integrity.

Influence on Thermal Properties and Heat Distribution

Shear force significantly influences thermal properties and heat distribution during extrusion. Friction generated by the screws accounts for approximately 80% of the heat required to melt plastic compounds. This heat distribution ensures uniform melting and prevents localized overheating, which could degrade material quality.

The design of the extruder’s mixing zones further enhances heat transfer. Forward- and reverse-conveying elements create pressure dynamics that improve thermal conductivity. Residence time distribution (RTD) also plays a vital role. Materials exposed to consistent shear forces experience uniform heating, resulting in better thermal stability.

For example, numerical simulations reveal that shear forces impact the microstructure of immiscible alloys during mixing. These forces influence viscosity ratios and turbulence, ensuring even heat distribution across the material. Such findings highlight the importance of shear force in maintaining thermal equilibrium during extrusion.

Changes in Mechanical Properties and Material Strength

Shear force directly affects the mechanical properties and strength of extruded materials. Variations in shear intensity can alter the molecular structure, leading to changes in tensile strength, elasticity, and durability.

Numerical research illustrates these effects:

- The peak shear strength of variable angle joint specimens increases nonlinearly with normal stress, while residual shear strength shows less correlation with joint morphology.

- At lower normal stress, specimens exhibit shear dilatancy, which diminishes at higher stress levels. This behavior demonstrates a negative correlation between normal and tangential displacements.

- Failure characteristics vary with joint angles. High-angle zones show vertical and shear cracks, while low-angle zones exhibit shear failure along the shear direction.

These findings emphasize the need to control shear force to achieve desired mechanical properties. For instance, excessive shear can cause fiber breakage, reducing material strength. Conversely, insufficient shear may result in incomplete mixing, compromising product quality.

Case Studies: Material Behavior Under Varying Shear Conditions

Case studies provide valuable insights into how shear force affects material behavior. Research on polypropylene-clay nanocomposites demonstrates that twin screw extruders achieve superior dispersion compared to single screw systems. Higher shear forces enhance exfoliation, improving mechanical and thermal properties.

Another study on natural fibers reveals that shear applied during compounding separates bundled fibers, reducing their diameter. This process enhances the material’s homogeneity but may compromise its structural integrity.

In industrial applications, optimizing shear force has proven essential for producing high-quality products. For example, adjusting screw speed and geometry in a plastic twin screw extruder ensures uniform mixing and consistent material properties. These case studies highlight the importance of tailoring shear force to specific applications.

Optimization Strategies for Plastic Twin Screw Extruder

Screw Design and Configuration Adjustments

Optimizing screw design is essential for improving the performance of a plastic twin screw extruder. Adjustments to screw geometry, such as pitch, flight depth, and intermeshing angle, directly influence shear force generation and material flow. For example, screws with deeper flights reduce shear intensity, while tighter intermeshing angles enhance mixing efficiency.

Operators often customize screw configurations to match specific material properties. High-viscosity plastics benefit from screws designed with larger flight depths to facilitate smoother flow. Conversely, low-viscosity materials require tighter intermeshing angles to ensure adequate shearing. These adjustments improve material homogeneity and reduce energy consumption during extrusion.

Balancing Shear Force and Temperature

Maintaining a balance between shear force and temperature is critical for achieving consistent extrusion quality. Excessive shear force can lead to overheating, while insufficient shear may result in incomplete mixing. Managing pressure within the extruder plays a pivotal role in controlling these variables.

For instance, a formula illustrates the relationship between pressure and temperature: ∆T (°C) = ∆P (bar) ÷ 2. Processing 500 kg/hr at a die pressure of 40 bar can increase melt temperature by approximately 20°C. Integrating a gear pump reduces discharge pressure, minimizing temperature spikes and wear on discharge screws. Closed-loop pressure control further enhances extrusion stability, ensuring uniform heat distribution and optimal material properties.

Tailoring Shear Force for Specific Plastic Applications

Tailoring shear force to specific applications enhances the performance of plastic materials. For example, adding plasticizers to PLA composites improves flexibility, impact resistance, and mechanical properties. Scanning electron microscopy (SEM) images reveal that plasticized PLA exhibits greater ductility compared to unplasticized composites, which display brittle behavior.

Flexural tests demonstrate that plasticized composites have lower flexural modulus values, indicating increased flexibility. Additionally, the addition of plasticizers reduces the glass transition temperature (Tg), facilitating easier processing. These adjustments highlight the importance of customizing shear force to meet the unique requirements of different plastic applications.

Real-Time Monitoring and Measurement Techniques

Real-time monitoring systems provide valuable insights into the extrusion process, enabling operators to optimize shear force effectively. Sensors measure key parameters such as temperature, pressure, and torque, offering precise control over extrusion conditions.

Advanced monitoring techniques, such as closed-loop systems, maintain consistent pressure settings and prevent fluctuations that could compromise product quality. These systems also detect anomalies in material flow, allowing operators to make immediate adjustments. By leveraging real-time data, manufacturers ensure that the plastic twin screw extruder operates at peak efficiency, delivering high-quality output.

Shear force remains a cornerstone of plastic twin screw extrusion, shaping material properties like mixing, thermal stability, and mechanical strength. Optimizing this force enhances product quality and process efficiency.

Continued innovation in shear force control will unlock new possibilities in plastic processing. Researchers and engineers should explore advanced techniques to refine extrusion outcomes further.

FAQ

What is the primary function of shear force in twin screw extrusion?

Shear force facilitates material melting, mixing, and homogenization. It ensures consistent product quality by influencing thermal and mechanical properties during extrusion.

How can operators control shear force in a twin screw extruder?

Operators adjust screw speed, customize screw geometry, and monitor real-time parameters like pressure and torque to regulate shear force effectively.

Why is balancing shear force and temperature important?

Balancing shear force and temperature prevents material degradation, ensures uniform mixing, and maintains optimal extrusion conditions for high-quality output.

Post time: Jun-11-2025