A plastic injection molding machine efficiently transforms raw plastic into precise, complex shapes. This process offers remarkable benefits:

- Producing intricate parts with high dimensional accuracy.

- Delivering consistent quality and repeatability.

- Reducing production costs in large-scale manufacturing.

Advanced designs, such as the Screw Type Injection Moulding Machine and Screw Type Injection Molding Machine, enhance material flow and optimize performance. Additionally, the Double Barrel Injection Moulding Machine and Screw Injection Molding Machine further improve efficiency and output in the manufacturing process.

Injection Unit in Screw Type Injection Moulding Machine

The injection unit in a Screw Type Injection Moulding Machine plays a pivotal role in transforming raw plastic pellets into a molten state and injecting them into the mold. This unit consists of three primary components: the hopper, barrel, and screw mechanism. Each part contributes to the efficiency and precision of the molding process.

Hopper

The hopper serves as the entry point for raw plastic materials. It holds the plastic pellets and feeds them into the barrel for further processing. Modern hoppers often include features like material drying systems to remove moisture from the pellets, ensuring optimal melt quality. By maintaining a consistent supply of material, the hopper supports uninterrupted production cycles in the Screw Type Injection Moulding Machine.

Barrel

The barrel is a cylindrical chamber that houses the screw mechanism. It heats the plastic pellets to their melting point using multiple heating zones. These zones—typically divided into feed, rear, middle, and front—allow precise temperature control, which is critical for achieving uniform melt quality. Correct temperature distribution within the barrel prevents issues like warpage, dimensional inaccuracies, and material degradation. This meticulous control ensures that the Screw Type Injection Moulding Machine delivers high-quality output consistently.

- Proper barrel zone temperatures are essential for efficient operation.

- Incorrect settings can lead to defects in the final product.

- Advanced designs improve energy efficiency and reduce operational costs.

Screw Mechanism

The screw mechanism is the heart of the injection unit. It rotates within the barrel, mixing and melting the plastic pellets while pushing the molten material forward. The design of the screw significantly impacts the melting and injection process. For instance, stationary screw designs enhance plastication by ensuring consistent shear exposure and shot volume. Additionally, features like poppet valves provide precise control by shutting off immediately when the screw stops.

In all-electric Screw Type Injection Moulding Machines, the screw mechanism offers unparalleled control over speed, pressure, and positioning. This precision minimizes variations between cycles, ensuring consistent fill rates and shot sizes. These advancements not only improve melt quality but also enhance the overall efficiency of the molding process.

- Automation and robotics integration further boost production output.

- Energy-efficient screw designs contribute to cost savings.

- Sustainable material usage aligns with modern manufacturing practices.

The injection unit in a Screw Type Injection Moulding Machine exemplifies the synergy of advanced engineering and precision control. Its components work together seamlessly to deliver high-quality, efficient, and reliable production.

Clamping and Mold Units

The clamping and mold units are critical components of a plastic injection molding machine. They ensure the mold remains securely closed during the injection process and facilitate the formation of precise, high-quality parts. These units consist of the mold, platens, and motor drive, each playing a distinct role in the molding process.

Mold

The mold serves as the cavity where molten plastic takes shape. Its design directly impacts the quality and consistency of the final product. Best practices in mold design emphasize uniform wall thickness to prevent defects like warping and sink marks during cooling. Smooth transitions between varying thicknesses, achieved through chamfers or fillets, further enhance structural integrity.

- Proper wall thickness avoids cosmetic flaws such as warping and sinking.

- Structural strength can be improved with ribs and gussets instead of increasing thickness.

- Design of Experiments (DOE) techniques help identify flaws early, ensuring optimal performance and reliability.

In a Screw Type Injection Moulding Machine, the mold’s precision ensures that intricate designs and tight tolerances are achievable. This capability makes it ideal for producing complex parts with consistent quality.

Platens

Platens are the large, flat plates that hold the mold in place and distribute clamping force evenly. Their design and structural integrity are vital for maintaining mold alignment and ensuring uniform pressure during the injection process. Key technical parameters that influence platen effectiveness include weight impact, load-bearing capacity, and structural optimization.

| Parameter | Impact on Mold Alignment |

|---|---|

| Weight Impact | Constitutes nearly 70% of the total weight of the machine, affecting stability and alignment. |

| Economic Significance | Optimizing design reduces raw material consumption, enhancing cost efficiency. |

| Performance Impact | Ensures proper mold alignment and uniform pressure distribution, critical for high-quality production. |

| Structural Optimization | Enhances size, shape, and material distribution for better alignment. |

| Load-Bearing Capacity | Improves durability and supports mold alignment under operational stresses. |

In a Screw Type Injection Moulding Machine, platens contribute to the machine’s ability to produce parts with high dimensional accuracy. Their robust design ensures durability and consistent performance, even under high clamping forces.

Motor Drive

The motor drive powers the clamping mechanism, enabling the mold to open and close with precision. It plays a crucial role in maintaining the speed and accuracy of the clamping process. Modern motor drives, particularly in all-electric machines, offer enhanced control over clamping force and positioning. This precision minimizes wear on the mold and reduces cycle times, improving overall efficiency.

Energy-efficient motor drives also contribute to cost savings and sustainability. By optimizing power consumption, they align with modern manufacturing practices that prioritize environmental responsibility. In a Screw Type Injection Moulding Machine, the motor drive ensures seamless operation, supporting high-speed production without compromising quality.

Tip: Regular maintenance of the motor drive can extend its lifespan and prevent unexpected downtime, ensuring uninterrupted production.

The clamping and mold units exemplify the synergy of engineering and precision in plastic injection molding machines. Their design and functionality directly influence the machine’s ability to produce high-quality parts efficiently and reliably.

Heating and Temperature Control Systems

Efficient heating and temperature control systems are essential for maintaining the quality and consistency of plastic injection molding processes. These systems ensure that the plastic material reaches the correct melting point and that the mold temperature remains stable throughout the cycle.

Barrel Heaters

Barrel heaters play a critical role in melting plastic pellets to their optimal temperature. They use multiple heating zones to achieve precise temperature control, which is vital for uniform melt quality. Effective temperature management enhances energy efficiency and improves the surface finish of molded parts.

- Proper control of barrel temperatures prevents material degradation, especially during extended residence times.

- Maintaining a target melt temperature of approximately 490°F ensures consistent material flow and reduces defects.

- Fluctuations in barrel temperature can negatively impact product quality, making close monitoring essential.

Advanced barrel designs often incorporate energy-efficient heating elements, reducing operational costs while maintaining high performance. These features align with modern manufacturing practices that prioritize sustainability and efficiency.

Mold Heaters

Mold heaters regulate the temperature of the mold, ensuring consistent part quality and reducing cycle times. The thickness of the mold material significantly influences heat transfer rates. Thicker sections retain heat longer, while thinner sections cool more rapidly. Adjusting mold heater settings based on material thickness prevents issues like warping and ensures uniform temperature distribution.

Scientific Molding techniques further optimize mold heater performance. These methodologies minimize start-up times, reduce scrap rates, and enhance process consistency. By maintaining precise mold temperatures, manufacturers achieve higher profitability and efficiency.

Temperature Control Mechanism

The temperature control mechanism ensures stability and accuracy during the molding process. Advanced strategies, such as expert adjustable fuzzy control, combine traditional PID control with fuzzy logic to optimize barrel temperature. This approach minimizes overshoot and oscillation, improving overall system performance.

| Control Strategy | Description |

|---|---|

| Expert Adjustable Fuzzy Control | Combines expert, fuzzy, and PID control for enhanced stability and accuracy. |

| PID Control | Traditional method prone to overshoot and oscillation. |

| Model Predictive Control | Tracks injection speed, improving precision in molding processes. |

Machine learning models, such as random forest algorithms, also contribute to energy efficiency by identifying key factors affecting energy consumption. These innovations enable manufacturers to balance energy use with part quality, further enhancing the sustainability of injection molding operations.

Hydraulic and Control Units

The hydraulic and control units are essential components of a plastic injection molding machine. These systems work together to ensure precise operation, efficient performance, and consistent product quality.

Hydraulic System

The hydraulic system powers the movement of the injection and clamping mechanisms. It generates the force required to inject molten plastic into the mold and maintain the clamping pressure during the molding process. Hydraulic pumps, valves, and cylinders form the core of this system, delivering controlled and reliable performance.

Modern hydraulic systems incorporate advanced technologies to enhance efficiency. Variable displacement pumps adjust the flow rate based on the machine’s operational needs, reducing energy consumption. Additionally, proportional valves provide precise control over pressure and flow, ensuring smooth and accurate movements. These features contribute to the machine’s ability to produce high-quality parts with minimal waste.

Tip: Regular maintenance of hydraulic components, such as checking for leaks and monitoring oil quality, can extend the system’s lifespan and prevent downtime.

Control Panel

The control panel acts as the brain of the injection molding machine. It monitors and regulates all machine functions, ensuring optimal performance. Equipped with sensors, the control panel collects real-time data on critical parameters such as temperature, pressure, and position. For instance:

- Sensors measure and provide feedback on temperature and pressure.

- Ring membrane sensors ensure precise position measurements using strain gauge cells.

Machine learning models integrated into the control panel further enhance its capabilities. These models predict part quality parameters like yield stress and modulus, optimizing process settings for consistent results. Experimental findings validate these models by comparing predicted values with actual outcomes, confirming their effectiveness in improving production efficiency.

The hydraulic and control units exemplify the synergy of mechanical and digital technologies, ensuring precision and reliability in plastic injection molding machines.

Feeding and Ejection Mechanisms

Feeding Unit

The feeding unit ensures a consistent supply of raw plastic material to the injection molding machine. It typically consists of a hopper and a feeding screw. The hopper stores plastic pellets and directs them into the barrel, where the material undergoes melting. Gravity and controlled vibrations facilitate the smooth flow of pellets, preventing blockages or interruptions during production.

Modern feeding units often include advanced features like material drying systems. These systems remove moisture from the pellets, which is critical for maintaining melt quality and preventing defects in the final product. Additionally, automated feeding mechanisms enhance efficiency by synchronizing material supply with the machine’s operational speed. This synchronization minimizes material wastage and ensures uninterrupted production cycles.

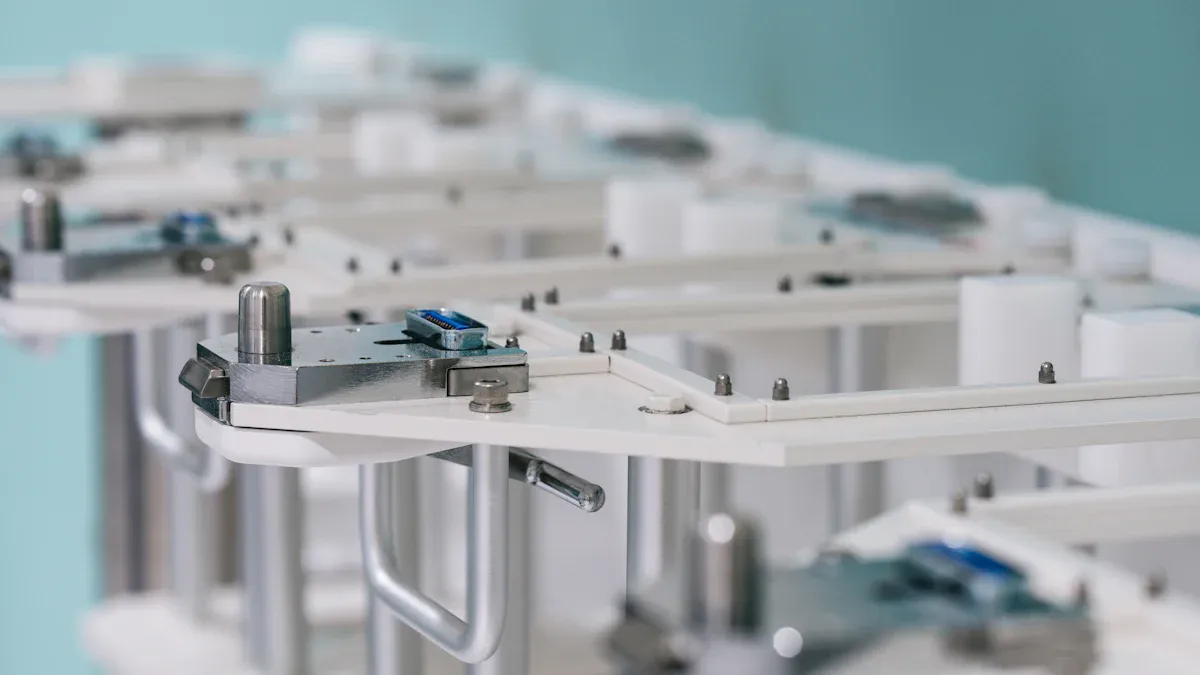

Ejection Unit

The ejection unit plays a vital role in removing the molded part from the mold cavity after cooling. It uses ejector pins, plates, or air blasts to release the finished product without causing damage. Precision in ejection timing and force is essential to maintain the integrity of the molded part and prevent defects like warping or cracking.

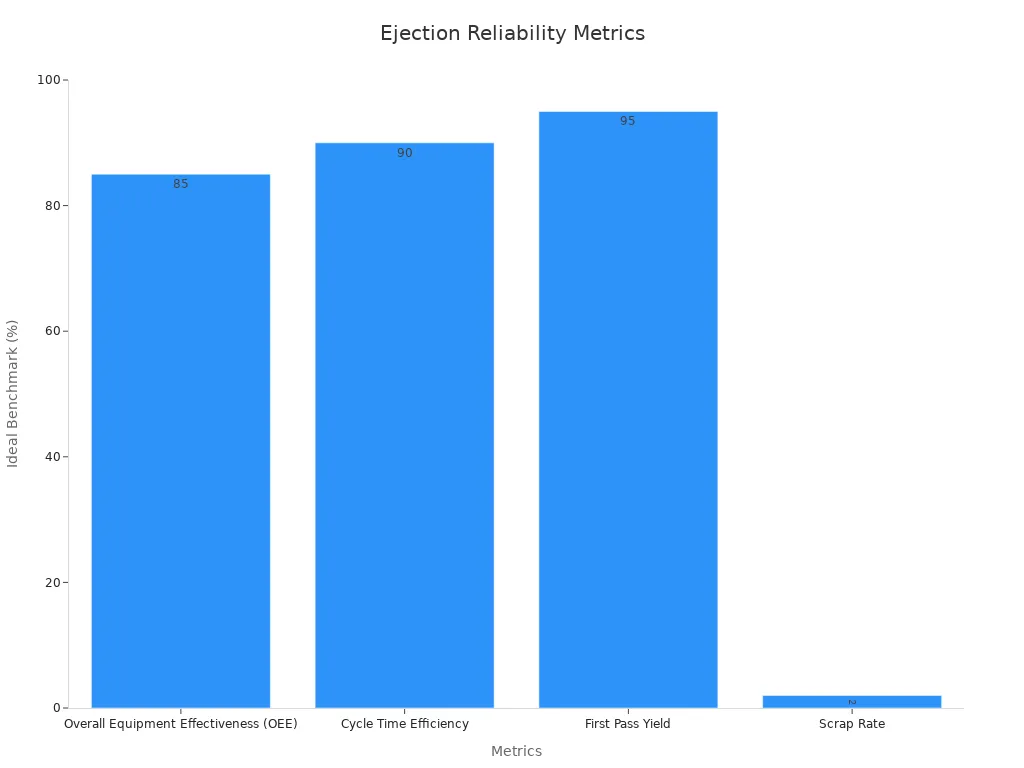

Reliable ejection units significantly reduce production cycle downtimes. Metrics such as Overall Equipment Effectiveness (OEE), Cycle Time Efficiency, and First Pass Yield (FPY) validate their performance. For instance:

| Metric | Description | Ideal Benchmark |

|---|---|---|

| Overall Equipment Effectiveness (OEE) | Measures manufacturing efficiency; calculated from availability, performance, and quality. | ~85% |

| Cycle Time Efficiency | Tracks time to complete one production cycle; lower times enhance throughput. | 90% or higher |

| First Pass Yield (FPY) | Percentage of products made correctly the first time; high values indicate effective processes. | >95% |

| Scrap Rate | Percentage of materials discarded; lower rates enhance profitability. | <2% |

Advanced ejection systems integrate sensors to monitor and adjust ejection force dynamically. These innovations ensure consistent part quality while minimizing wear on the mold and machine components. Regular maintenance of the ejection unit further enhances its reliability and extends its operational lifespan.

A plastic injection molding machine integrates advanced components to deliver exceptional performance. Each part contributes to production efficiency, quality, and reliability. Mastering these systems ensures optimal results.

| Metric | Description |

|---|---|

| Production Efficiency | Reflects how effectively raw materials are transformed into finished products. |

| Scrap Rate | Indicates the percentage of production that does not meet quality standards. |

| Machine Downtime | Impacts production efficiency and operational costs, essential for profitability. |

Understanding these metrics highlights the machine’s role in achieving consistent, high-quality output.

FAQ

1. What materials can be used in plastic injection molding machines?

Plastic injection molding machines process thermoplastics like ABS, polypropylene, and nylon. They also handle engineering plastics such as polycarbonate and PEEK.

2. How does temperature control impact product quality?

Precise temperature control ensures uniform melt quality, reduces defects, and enhances dimensional accuracy. It prevents material degradation during extended processing cycles.

3. What maintenance practices improve machine performance?

Regular lubrication, hydraulic system checks, and cleaning of feeding units prevent wear and downtime. Monitoring sensors ensures consistent operation and extends machine lifespan.

Post time: May-28-2025