I trust the PVC Pipe screw barrel for extrusion because it uses premium alloy steel and advanced coatings. I see how these features help it resist heat, pressure, and wear. Compared to standard options, a premium PVC pipe single screw barrel lasts up to six times longer. I also rely on a single screw barrel for blowing molding and a PE pipe extruder single screw barrel for tough jobs.

Material and Construction of PVC Pipe Screw Barrel for Extrusion

Premium Alloy Steel Selection

When I choose a PVC Pipe screw barrel for extrusion, I focus on the alloy steel. The right steel makes all the difference in durability and performance. I rely on materials like 38CrMoAlA and 42CrMo because they offer high strength and excellent wear resistance. These steels handle the tough conditions of extrusion, including high temperatures and pressure. I also look for barrels with bimetallic liners or stainless steel cladding when I need extra protection against corrosion from PVC’s chlorine compounds.

Here are some of the most common alloy steels and their uses:

| Alloy Steel / Material | Key Characteristics | Application in PVC Screw Barrels |

|---|---|---|

| AISI 4140 | Good strength, heat treatable, widely available | Standard for most PVC screw barrels |

| AISI 4340 | Higher strength, better heat treatment penetration | Used for deep flights or small diameter screws |

| Nitralloy 135-M | Aluminum for nitriding, improved wear resistance | Nitrided surfaces for longer life |

| 17-4 PH Stainless Steel | Strong, corrosion resistant | Smaller screws needing corrosion resistance |

| D2 and H13 Tool Steels | High wear resistance, heat treatable, corrosion resistant | High abrasion areas, sleeves, plasticizing screws |

| CPM Tool Steels (CPM 10V, etc.) | Superior abrasion and corrosion resistance | Filled compounds, long-lasting wear resistance |

I always select the steel grade based on the demands of the extrusion process. High-strength alloy steels and bimetallic alloys give me confidence that the PVC Pipe screw barrel for extrusion will last through years of heavy use.

Advanced Surface Treatments and Hardness

Surface treatments play a huge role in how long my screw barrels last. I use nitriding to create a hard layer on the steel, which can reach up to 70 HRC. This layer resists wear and stress, even when the barrel faces high pressure and temperature. Chrome plating adds a smooth surface and reduces friction, making cleaning easier and improving melt flow. Sometimes, I choose bimetallic alloys or tungsten carbide coatings for even greater abrasion resistance.

Tip: Nitriding forms a nitride layer about 0.5-0.8mm deep, which protects the barrel from wear and corrosion. Chrome plating, usually 10-50 microns thick, keeps the surface slick and helps prevent material buildup.

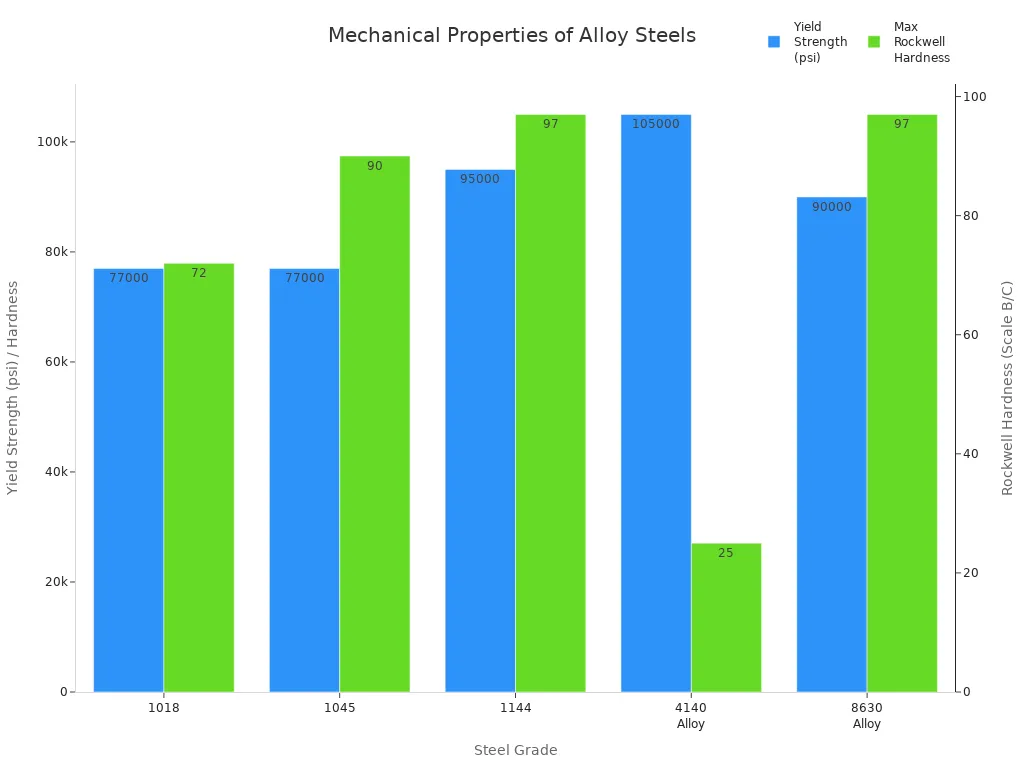

Here’s a quick look at the mechanical properties of the steels I use:

| Steel Grade | Yield Strength (psi) | Max Rockwell Hardness (Scale) | Notes on Properties and Use |

|---|---|---|---|

| 4140 Alloy | 60,000 – 105,000 | C20 – C25 | Tough, ductile, wear resistant |

| 17-4 PH Stainless | 110,000 | C40 | Strong, corrosion resistant |

| D2 Tool Steel | 90,000 | C55 | High wear resistance, corrosion resistant |

I always match the surface treatment to the type of plastic and additives I use. This way, my PVC Pipe screw barrel for extrusion stays reliable and efficient.

Precision Manufacturing and Structural Integrity

Precision manufacturing is the backbone of a durable screw barrel. I trust CNC machining to keep tolerances tight, sometimes as precise as ±0.01 mm. This accuracy ensures the screw and barrel mesh perfectly, which is critical for efficient PVC conveyance and mixing. I pay close attention to screw geometry—flights, channel depth, pitch, and compression ratio. These features help me control pressure and temperature, preventing material degradation.

- I use vacuum vent sections and mixing elements to remove trapped gases and blend additives thoroughly.

- Heating elements and cooling channels in the barrel let me control temperature zones, keeping the melt stable.

- Integrated control systems allow me to monitor and adjust the process in real time, maintaining dimensional accuracy and preventing defects.

If I notice any wear or dimensional deviation, I act fast. Even small changes can reduce conveying capacity and plasticizing efficiency, leading to uneven pipe walls or unmelted particles. By maintaining precision, I ensure my PVC Pipe screw barrel for extrusion delivers consistent quality and long service life.

Design and Operational Benefits of PVC Pipe Screw Barrel for Extrusion

Optimized Screw Geometry and Uniform Feeding

When I select a PVC Pipe screw barrel for extrusion, I pay close attention to the screw geometry. The right design helps me achieve smooth and uniform feeding of PVC material. I look for features that support efficient transport and mixing. Here are some key design elements I consider:

- Deeper flights and channels in the conveying section move material quickly without causing too much shear.

- The channel depth decreases from the conveying zone to the metering zone, which balances melting and mixing.

- A larger flight pitch moves more material with less force, while reverse elements help control flow and improve mixing.

- The feed section keeps material flowing and prevents blockages.

- The compression section melts and mixes the PVC, using heat from friction.

- The metering section ensures a steady output of molten material.

I always make sure the screw geometry matches the properties of the PVC and the needs of the extrusion process. This careful design helps me avoid defects and keeps the material flow steady.

If I notice any wear on the screw, I act quickly. Even small changes in geometry can cause uneven flow and defects in the final pipe. By keeping the screw in top shape, I maintain high-quality extrusion and reduce waste.

Integrated Heating and Cooling Systems

Precise temperature control is essential for producing strong and consistent PVC pipes. I rely on advanced heating and cooling systems built into the screw barrel. These systems help me keep the temperature just right during every stage of extrusion.

| System Type | Description | Application Context |

|---|---|---|

| Heating System | Electric heating methods, such as induction and resistance heating, applied outside the barrel | Provides the heat needed to melt PVC |

| Cooling System | Water or air cooling systems; air cooling for small extruders, water for larger ones | Prevents overheating and keeps temperature stable |

I use temperature sensors to monitor the process in real time. Automated controls adjust the heating and cooling as needed. This setup keeps the melt temperature steady, which is important for pipe quality and dimensional accuracy.

- Temperature control in each zone ensures the PVC melts completely and evenly.

- Proper die temperature prevents the pipe from sagging or solidifying too soon.

- Cooling systems help the pipe keep its shape and reduce internal stress.

With these systems, I can quickly adjust to changes and avoid defects like uneven walls or rough surfaces.

Resistance to Wear, Corrosion, and High Pressure

The PVC Pipe screw barrel for extrusion faces tough conditions. I choose barrels made from special alloys and with advanced coatings to resist wear and corrosion. PVC processing can release hydrochloric acid, which attacks regular steel. To prevent this, I use bimetallic barrels with nickel-rich liners and hard coatings like tungsten carbide.

- Adhesive wear happens when metal parts rub together.

- Abrasive wear comes from fillers like glass fibers or minerals in the PVC.

- Corrosive wear is caused by chemicals released during processing.

I also make sure the screw and barrel materials match. This prevents problems from different rates of expansion when heated. Regular checks and maintenance help me spot wear early and avoid major repairs.

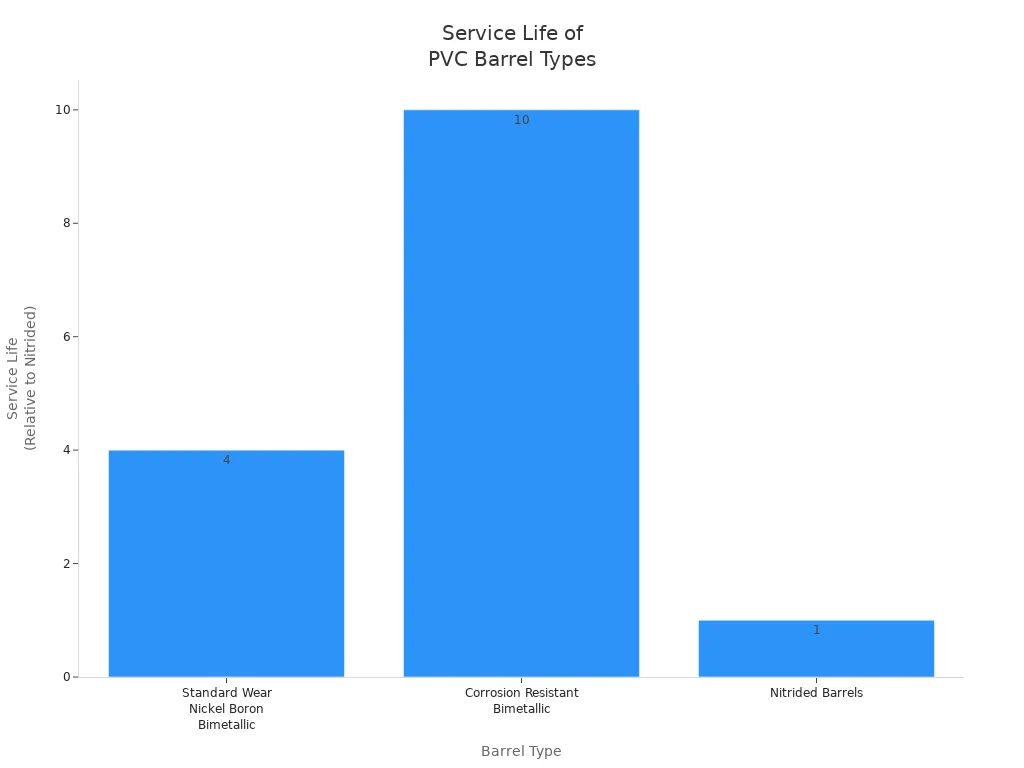

| Barrel Type | Wear Resistance | Corrosion Resistance | Service Life Compared to Nitrided Barrels |

|---|---|---|---|

| Standard Wear Nickel Boron Bimetallic | Excellent abrasion resistance | Moderate corrosion resistance | At least 4 times longer |

| Corrosion Resistant Bimetallic | Excellent wear resistance | Excellent against HCl and acids | Over 10 times longer in corrosive atmospheres |

| Nitrided Barrels | High surface hardness | Poor corrosion resistance | Baseline (1x) |

By using these materials and designs, I extend the life of my equipment and keep production running smoothly, even under high pressure and with abrasive materials.

Consistent Extrusion Quality and Extended Service Life

I know that consistent quality is key in PVC pipe production. I monitor important parameters like temperature, pressure, and speed to keep the process stable. I use precision tools to check the pipe’s dimensions and look for surface defects. Automated systems help me catch problems early and keep the process on track.

- I track output volume, defect rates, and energy use to measure performance.

- Regular maintenance and alignment checks help me avoid downtime.

- Durable screw barrels with bimetallic coatings reduce how often I need to stop for repairs.

When I invest in a high-quality PVC Pipe screw barrel for extrusion, I see fewer breakdowns and less waste. My maintenance costs go down, and I can process recycled materials more easily. I also notice lower energy use because the equipment runs more efficiently.

In my experience, these benefits add up to significant cost savings and higher productivity. I can meet delivery deadlines and keep my customers happy.

I invest in a PVC Pipe screw barrel for extrusion because it delivers long-lasting performance and consistent pipe quality.

- Modular barrel designs and advanced materials reduce downtime and maintenance costs.

- Regular inspections and proper coatings help me meet industry standards.

| Benefit | Result |

|---|---|

| High durability | Lower operational costs |

| Advanced technology | Improved customer satisfaction |

FAQ

How do I maintain my PVC Pipe screw barrel for extrusion?

I clean the barrel regularly. I inspect for wear and corrosion. I replace worn parts quickly. I use recommended lubricants and monitor temperature settings.

Tip: Schedule monthly inspections to catch early signs of wear.

What surface treatment works best for high-abrasion PVC extrusion?

I prefer nitriding for most jobs. I use bimetallic or tungsten carbide coatings when I process abrasive compounds. These treatments extend service life and resist wear.

Can I customize the screw geometry for different PVC pipe sizes?

I work with manufacturers to adjust screw diameter, pitch, and flight depth. Custom geometry helps me achieve optimal melt flow and consistent pipe quality for any size.

| Customization Option | Benefit |

|---|---|

| Diameter | Matches pipe thickness |

| Pitch | Controls material flow |

| Flight Depth | Improves mixing quality |

Post time: Aug-27-2025