Twin-screw extruders have revolutionized polymer processing by enabling precise control and high efficiency. Advanced designs of the extruder double screw, such as those optimizing rotational speed, have reduced energy consumption by 45% while increasing pressure by 65%. Digitalization further enhances process monitoring, ensuring consistent quality. Energy-efficient systems minimize waste, supporting sustainable operations of the plastic profile extrusion machine. These innovations unlock new possibilities, from producing intricate components to refining materials for diverse industries, including the use of twin screw for extruder applications.

Understanding Twin-Screw Extruders

Defining Twin-Screw Extruders

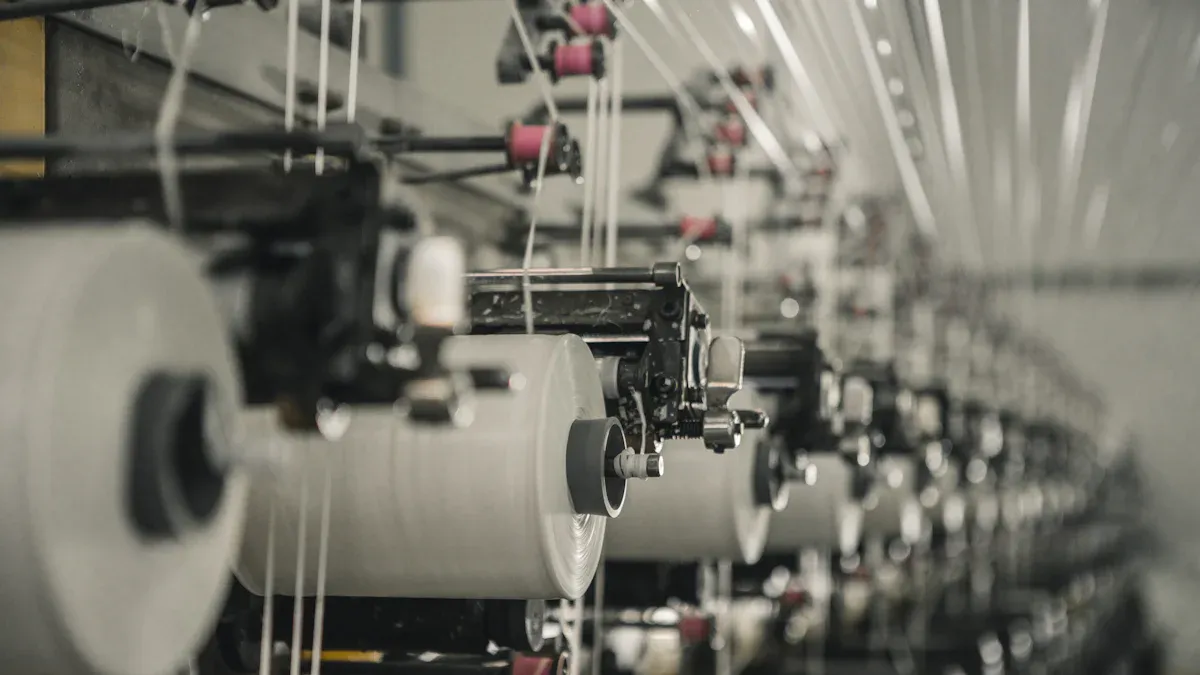

Twin-screw extruders are advanced machines used in polymer processing to melt, mix, and shape materials. Unlike single-screw extruders, they feature two intermeshing screws that rotate within a barrel, offering superior control over material flow and mixing. Their design allows for precise adjustments to shear, temperature, and pressure, making them ideal for complex applications.

The following table highlights key aspects that define twin-screw extruders:

| Aspect | Description |

|---|---|

| Geometry | Features two screws with intermeshing geometry, unlike single-screw machines. |

| Mechanism | Employs a unique mechanism for melting, mixing, and pumping materials. |

| Applications | Suitable for advanced processes like multi-phase blending and reactive extrusion. |

| Complexity | Requires specialized design and nomenclature due to its intricate structure. |

| Comparison | Outperforms single-screw extruders in mixing, temperature control, and process flexibility. |

These characteristics make twin-screw extruders indispensable in industries requiring high precision and efficiency.

Importance in Polymer Processing and Compounding

Twin-screw extruders play a pivotal role in polymer processing by enabling efficient compounding, blending, and devolatilization. Their ability to handle diverse materials, including thermoplastics, elastomers, and fillers, makes them versatile tools in manufacturing.

Research shows that twin-screw extruders can double throughput in high-speed operations without excessive heat generation. This efficiency stems from their advanced screw design, which optimizes material flow and mixing. Additionally, their superior temperature control ensures consistent product quality, even in demanding applications.

The table below compares their capabilities with single-screw extruders:

| Feature | Twin-Screw Extruder | Single-Screw Extruder |

|---|---|---|

| Mixing | Superior mixing capabilities due to co-rotation | Limited mixing ability |

| Shear Control | Enhanced shear control for various materials | Less precise shear control |

| Process Flexibility | High flexibility in processing different materials | Less adaptable |

| Temperature Control | Better control of temperature profiles | Less effective control |

| Application | Suitable for complex processes like multi-phase blending | Basic processing tasks |

These advantages have made twin-screw extruders the preferred choice for polymer compounding, enabling manufacturers to produce high-quality materials efficiently.

Innovations in Twin-Screw Extruders

Advanced Screw Designs

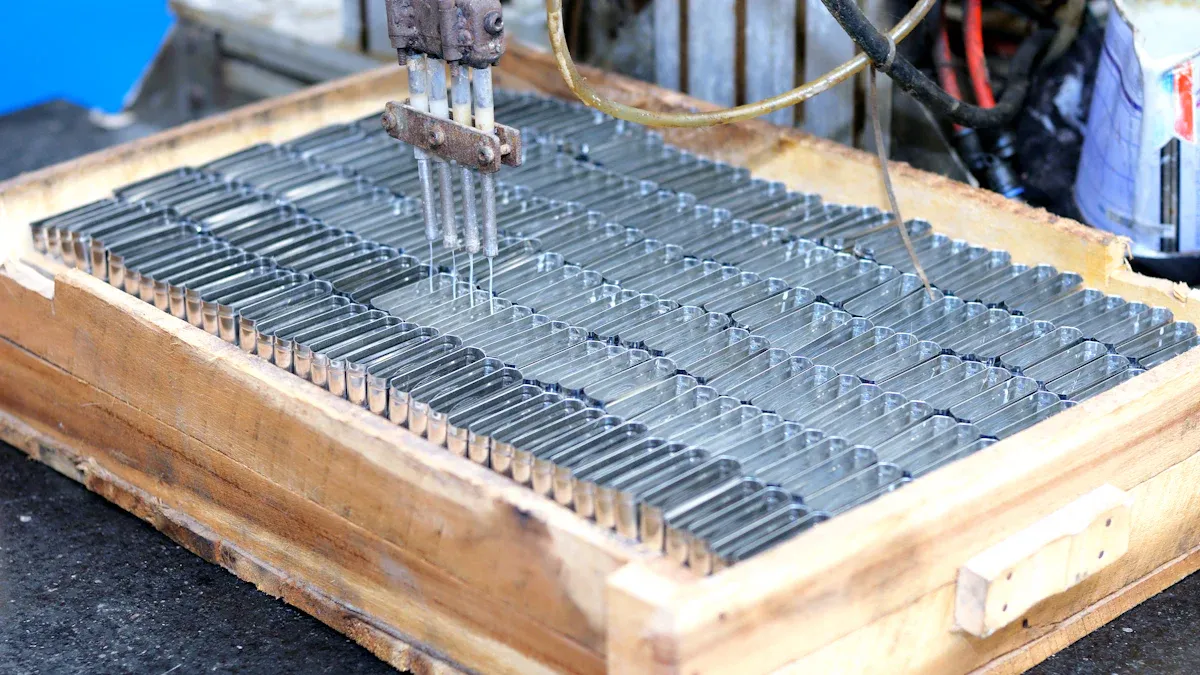

Recent advancements in screw designs have significantly enhanced the performance of twin-screw extruders. These innovations focus on improving efficiency, durability, and precision. Key developments include:

- Improved Ball Circuit Designs: Optimized systems reduce noise and vibration, ensuring smoother operation and less wear.

- High-Efficiency Lead Shapes: Enhanced lead shapes increase load capacity and operational efficiency.

- Advanced Materials: High-grade materials improve durability and resistance to corrosion.

- Precision Manufacturing Techniques: Tighter tolerances and better surface finishes reduce friction and enhance accuracy.

- Sealing and Lubrication Innovations: New technologies extend the lifespan of components while maintaining efficiency.

- Nut Designs: Innovative configurations minimize axial play and improve precision.

- Integration with Electronics: Smart ball screws enable predictive maintenance by monitoring performance.

- Miniaturization: Smaller screw designs cater to precision applications.

- Customization: Tailored solutions address specific application needs.

- Energy Efficiency: Design improvements reduce energy consumption during operation.

Research highlights that many processors still rely on outdated screw designs, which limits their productivity. By adopting advanced screw designs, manufacturers can achieve better melt uniformity and higher throughput, leading to improved overall performance.

Digitalization and Smart Controls

Digitalization has transformed twin-screw extruders by integrating smart controls and advanced monitoring systems. These technologies enhance efficiency, reduce downtime, and improve product quality.

| Year | Company | Technology Description | Efficiency Gains |

|---|---|---|---|

| 2023 | Coperion GmbH | Launched a new series of twin-screw extruders with enhanced energy efficiency | Improved energy efficiency |

| Improved control systems for processing recycled plastics | Enhanced operational efficiency | ||

| Integration of Industry 4.0 technologies (IoT, AI, ML) into extruders | Predictive maintenance capabilities |

Case studies demonstrate the effectiveness of these innovations. For instance:

- A PE pipe manufacturer implemented a smart PLC system with IoT monitoring. This reduced equipment failure rates by 20%, improved product consistency, and decreased energy consumption by 15%.

- A PVC profile producer adopted a digital twin system, reducing defect rates from 4% to 1.2% and shortening the production debugging period by 30%.

These examples highlight how digitalization enables manufacturers to optimize operations and achieve superior results.

Energy Efficiency and Sustainability

Energy efficiency has become a cornerstone of modern twin-screw extruder design. Manufacturers now prioritize reducing energy consumption while maintaining high output rates.

| Extruder Size | Power Usage Range | Consumption Rate (kWh/kg) |

|---|---|---|

| Small-Scale (10–50 mm) | 5–50 kW | Low-Intensity: 0.10–0.30 |

| Mid-Sized (50–120 mm) | 50–300 kW | Moderate-Intensity: 0.30–0.60 |

| Large Industrial (120+ mm) | >500 kW | High-Intensity: 0.60–1.00 or higher |

Optimization strategies such as energy-efficient motors, advanced screw designs, and process control systems further enhance sustainability. Twin-screw extruders also minimize waste and maximize productivity, contributing to eco-friendly manufacturing practices. Their ability to provide better mixing and material distribution reduces the energy required for processing, improving volumetric throughput and overall efficiency.

Empirical data supports these claims, showing that optimizing production amounts and minimizing idle operation time can significantly lower environmental impact. These advancements align with the industry’s growing focus on sustainable manufacturing.

Impacts on Polymer Industries

Improved Product Quality

Innovations in twin-screw extruders have significantly enhanced product quality across polymer industries. Advanced screw designs and real-time monitoring tools ensure precise control over critical parameters, resulting in consistent and superior output. For instance, modern extruders utilize technologies like near-infrared (NIR) and Raman spectroscopy to monitor quality attributes in real time. These tools provide immediate feedback, enabling manufacturers to maintain optimal conditions throughout the process.

The following table highlights key measures of quality improvement facilitated by twin-screw extruder innovations:

| Measure | Description |

|---|---|

| Moisture Content | Monitored to ensure optimal granulation conditions. |

| API Content Uniformity | Assessed to maintain consistent active pharmaceutical ingredient distribution. |

| Blend Uniformity | Evaluated to ensure homogeneity in the mixture before granulation. |

| Granule Size Distribution | D10, D50, and D90 fractions monitored to assess particle size variations in real-time. |

| Solid State of Active Ingredient | Ensured to maintain the efficacy of the active ingredient throughout the process. |

| Real-time Monitoring Tools | Utilized tools like NIR and Raman spectroscopy for immediate feedback on quality attributes. |

Industry reports confirm these advancements. For example, the “Twin Screw Extruders Market Size, Growth, Trends, Report 2034″ highlights how technological improvements in screw designs and cooling mechanisms optimize production processes and enhance product quality. These innovations have made twin-screw extruders indispensable for manufacturers aiming to meet stringent quality standards.

Cost and Time Efficiency

Twin-screw extruders have redefined cost and time efficiency in polymer processing. Their ability to handle complex operations with minimal energy consumption reduces operational expenses. Companies leveraging optimized screw designs report up to a 20% improvement in energy efficiency, enhancing mixing performance and product homogeneity. Additionally, the integration of Model Predictive Control (MPC) systems has increased throughput by 15% while reducing off-spec material by 10%.

Other notable advancements include the use of heat exchangers for thermal energy recovery, which has led to a 12% reduction in energy consumption. These innovations not only lower production costs but also minimize environmental impact.

Key economic benefits include:

- Enhanced energy efficiency through advanced screw designs.

- Increased throughput with predictive control systems.

- Reduced waste via automated extrusion systems.

The North America Plastic Extrusion Machinery Market underscores the economic significance of twin-screw extruders. Their role in manufacturing flexible packaging, medical tubing, and other high-demand products demonstrates their value in achieving cost-effective and efficient production.

Enabling New Applications

Recent advancements in twin-screw extruder technology have opened doors to innovative applications across industries. In precision medicine, these machines enable the creation of customized pharmaceutical formulations, ensuring tailored treatments for individual patients. The integration of artificial intelligence further enhances operational efficiency by enabling predictive maintenance and process optimization.

Sustainability-focused innovations have also expanded the scope of twin-screw extruders. These machines now process eco-friendly materials like biodegradable polymers and recycled plastics, aligning with global efforts to reduce environmental impact. Additionally, their versatility supports the production of high-performance materials for automotive, aerospace, and consumer goods industries.

Market research reports highlight these developments. For instance, the “Rubber Twin-Screw Extrusion Equipment Market” emphasizes advances in materials science and automation, which drive the adoption of twin-screw configurations for higher throughput and superior product quality. These innovations continue to push the boundaries of what twin-screw extruders can achieve, enabling manufacturers to explore new frontiers in polymer processing.

Twin-screw extruders continue to redefine polymer processing by enhancing efficiency, sustainability, and versatility. Recent innovations, such as modular designs and advanced screw configurations, enable manufacturers to adapt quickly to evolving demands.

- These machines now support sustainable practices, including waste-to-product applications and the production of bio-based plastics.

- Automation and smart technologies are projected to boost productivity by up to 20%, ensuring consistent quality and operational efficiency.

Staying informed about these advancements will help industries leverage cutting-edge solutions for future growth.

FAQ

What are the main advantages of twin-screw extruders over single-screw extruders?

Twin-screw extruders offer superior mixing, better temperature control, and higher process flexibility. These features make them ideal for complex polymer processing applications.

How do advanced screw designs improve extrusion performance?

Advanced screw designs enhance material flow, reduce energy consumption, and improve mixing precision. These innovations ensure consistent product quality and higher operational efficiency.

Can twin-screw extruders support sustainable manufacturing?

Yes, twin-screw extruders minimize waste and process biodegradable or recycled materials. Their energy-efficient systems align with eco-friendly manufacturing practices. ♻️

Tip: Regular maintenance ensures optimal performance and extends the lifespan of twin-screw extruders.

Post time: May-30-2025