Manufacturers choose critical upgrades for Twin Screw Plastic Extruder bulk production to boost efficiency and durability. Common improvements include dryerless technology, new square barrels, and re-engineered components, as shown below:

| Upgrade Feature | Description | Benefits |

|---|---|---|

| Dryerless Technology | Removes drying steps | Saves energy and space |

| New Square Barrels | Faster heat-up times | Reduces downtime |

| Re-engineered Components | Designed for longer life | Increases efficiency |

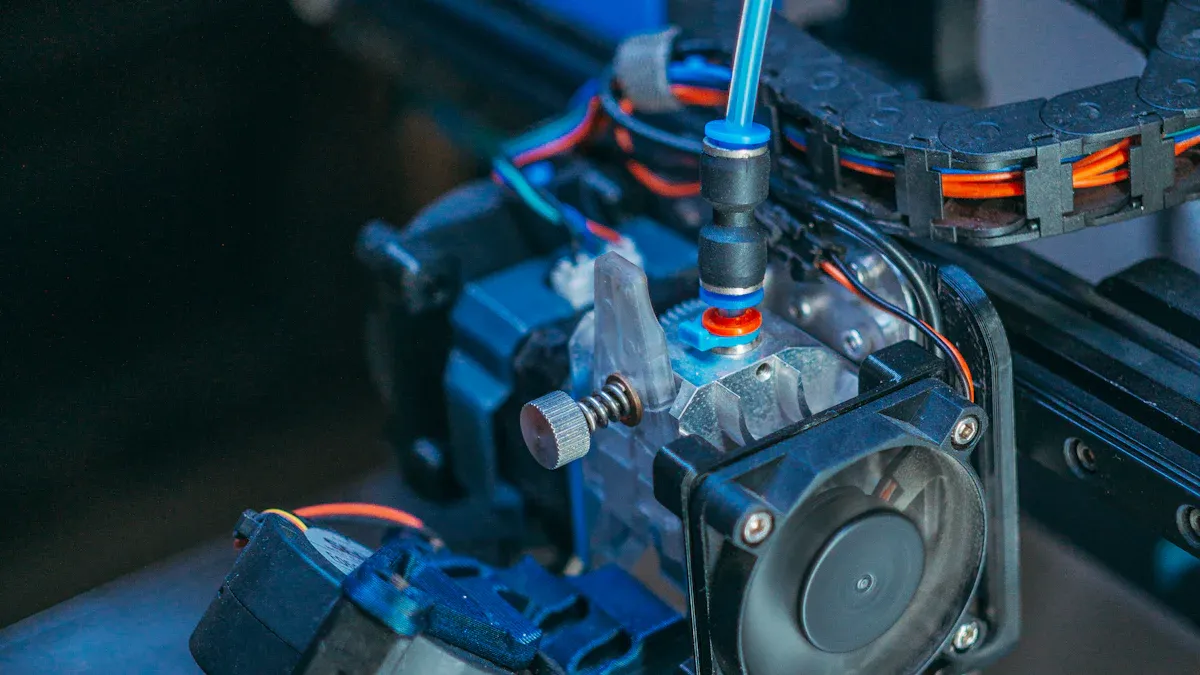

Advanced CNC technology in Twin Plastic Screw Barrel and Extrusion Machine Single Screw Barrel production increases precision, durability, and reduces maintenance. The plastic twin screw extruder benefits from these upgrades with enhanced mixing capabilities and improved resource management.

Essential Upgrades for Twin Screw Plastic Extruder Bulk Production

Performance Challenges in High-Volume Manufacturing

Manufacturers face several obstacles when operating Twin Screw Plastic Extruder systems for bulk production. Rising costs for materials and energy create pressure to improve efficiency. The price of high-grade stainless steel increased by 14% from 2022 to 2023. Electricity costs for industrial equipment rose by 11% in Europe. These changes force companies to seek better energy management and material usage.

Outdated extruder systems contribute to higher waste rates. For example, waste material in rigid PVC pipe applications usually measures around 1.5%. Worn screws can raise this rate to 10%, which leads to increased production costs. Not addressing screw wear results in expensive consequences for manufacturers.

Tip: Regular maintenance and timely upgrades help reduce waste and control costs in high-volume operations.

Manufacturers also encounter challenges with throughput and temperature control. Upgrades such as high-pressure cooling systems and insulation gaskets improve heat exchange and maintain stable processing conditions. Implementing side feeding increases filler loading levels, while long-pitch screw elements maximize material flow and prevent blockages.

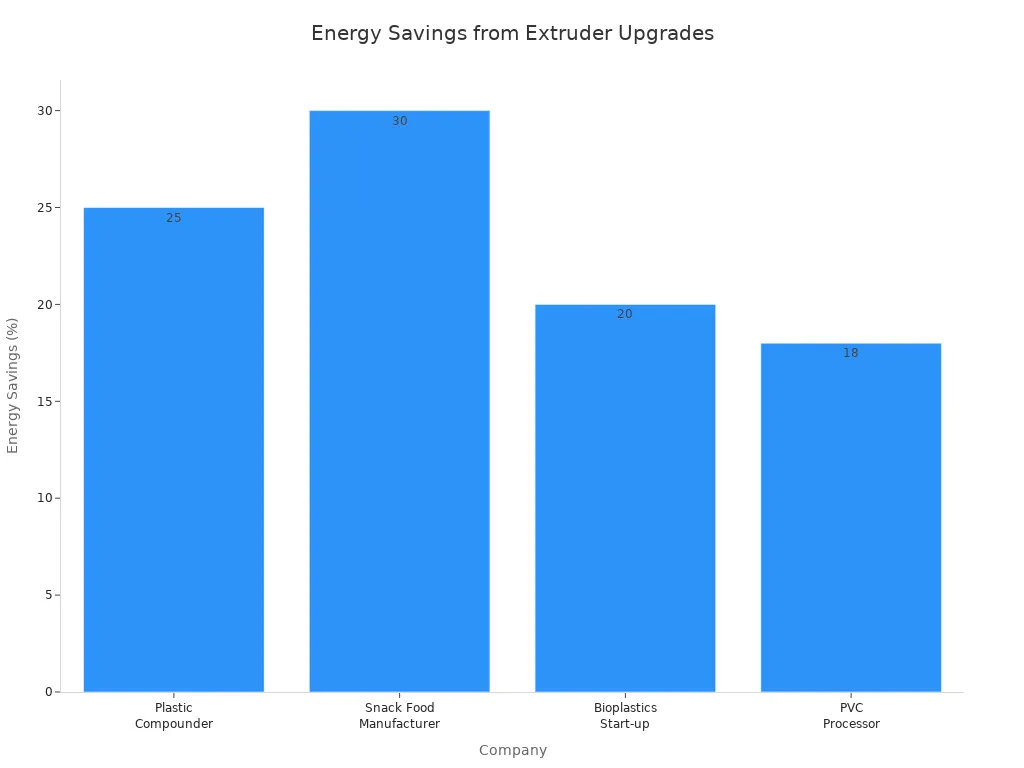

Energy consumption remains a critical concern. Optimizing screw design and using advanced temperature control systems lead to significant energy savings. Retrofitting with servo motor technology boosts operational efficiency. Adjustments in screw design and feeding configuration can directly impact mechanical energy usage.

Why Upgrades Are Urgent for Today’s Market

The market for Twin Screw Plastic Extruder technology continues to evolve rapidly. Manufacturers must respond to new trends and customer demands to remain competitive. The table below highlights key market trends driving the need for immediate upgrades:

| Trend Type | Description |

|---|---|

| Multi-functionality | Twin screw extruders now serve polymer, food, feed, and other industries. |

| Large-scale production | Large units lower costs and support petrochemical industry needs. |

| Precision | High-value products require precise extrusion, such as multi-layer co-extruded films. |

| Intelligent technologies | Real-time monitoring and control improve accuracy and stability. |

Customers expect higher product quality and consistency. Twin Screw Plastic Extruder systems deliver superior mixing and degassing, which reduces defects and improves output. These features prove essential for technical parts with strict quality requirements. Upgrades in extruder technology enhance accuracy and control, while intelligent systems allow real-time adjustments to critical parameters.

Manufacturers who invest in essential upgrades experience significant returns. Lower maintenance costs and reduced downtime result in long-term savings. Robust designs ensure durability and improved productivity, making upgraded Twin Screw Plastic Extruder systems a reliable choice for bulk production.

Advanced CNC and Nitriding Technology for Twin Screw Plastic Extruder

CNC Precision and Consistency in Extruder Manufacturing

Modern manufacturing demands high precision and repeatability. Advanced CNC technology delivers these qualities for Twin Screw Plastic Extruder components. CNC machines use computer control to shape screws and barrels with exact measurements. This process ensures each part fits perfectly and performs reliably in high-volume production.

Key features of advanced CNC systems include artificial intelligence, advanced sensors, and servo-driven extruders. These features work together to optimize the extrusion process. For example, artificial intelligence analyzes data and predicts outcomes, allowing real-time adjustments to temperature and pressure. Advanced sensors monitor critical parameters, providing immediate feedback for corrections. Servo-driven extruders regulate screw speed and pressure, which ensures uniformity in the final product. High-efficiency heaters and automated control systems further improve energy use and product quality.

| Feature | Description |

|---|---|

| Artificial Intelligence (AI) | Optimizes extrusion processes by analyzing data, predicting outcomes, and enabling real-time adjustments to parameters like temperature and pressure. |

| Advanced Sensors | Monitors temperature, pressure, and material flow rates with high precision, providing real-time feedback for immediate corrections. |

| Servo-driven Extruders | Offers accuracy in regulating screw speed and pressure, ensuring uniformity in extruded products. |

| Energy Efficiency | High-efficiency heaters minimize energy loss and provide rapid, uniform heating for process consistency. |

| Automated Control Systems | Dynamically adjust process parameters in real-time to enhance efficiency and product quality. |

These advancements help manufacturers achieve consistent results, reduce waste, and maintain high standards in every batch.

Nitriding for Enhanced Durability and Wear Resistance

Nitriding technology plays a vital role in extending the lifespan of screws and barrels in Twin Screw Plastic Extruder systems. This process treats the metal surface in a high-nitrogen atmosphere at about 950°F (510°C). The result is a hard outer layer with a case hardness between 55 and 65 Rc. This hard layer resists wear from abrasive materials and maintains its strength over time.

Nitriding offers several advantages over other surface treatments. It provides better wear resistance than carburizing, with a nitrided layer showing 50% lower wear intensity under similar loads. Tribological studies confirm that nitriding outperforms carburizing, even when the carburized layer is thicker. The process creates a thin, hard case that gradually decreases in hardness, which helps protect against surface damage.

- Nitriding technology provides superior wear resistance compared to carburizing for extruder screws and barrels.

- The nitrided layer shows a 50% lower wear intensity under similar load conditions.

- Tribological studies indicate that nitriding is more beneficial than carburizing due to better wear properties despite a thicker carburized layer.

- Nitriding involves treating screws or barrels in a high nitrogen atmosphere at around 950°F (510°C), resulting in high case hardness (55 – 65 Rc).

- The nitriding process creates a thin case that diminishes in hardness, which helps maintain wear resistance against abrasive materials.

- Proper nitriding steels, such as Crucible Nitriding 135, enhance the hardness achieved through the process.

Nitriding also helps prevent common failure modes in extruder components. These include low-cycle bending fatigue, brittle fracture, and contact fatigue. The table below outlines these failure modes and how nitriding addresses them.

| Failure Mode | Description |

|---|---|

| Low-cycle bending fatigue | Primary failure mechanism leading to brittle fracture of the pinion gear. |

| Brittle fracture | Resulting from low-cycle bending fatigue, indicating a critical failure point. |

| Carburization and surface finish | Excess case carburization and poor surface finish lower the fatigue limit, contributing to breakage. |

| Contact fatigue | Common in gear failures, leading to significant operational issues. |

| Tooth bending fatigue | Another prevalent mode of failure in gears, often exacerbated by poor material treatment. |

By choosing nitriding, manufacturers increase the durability of their Twin Screw Plastic Extruder equipment and reduce the risk of costly breakdowns.

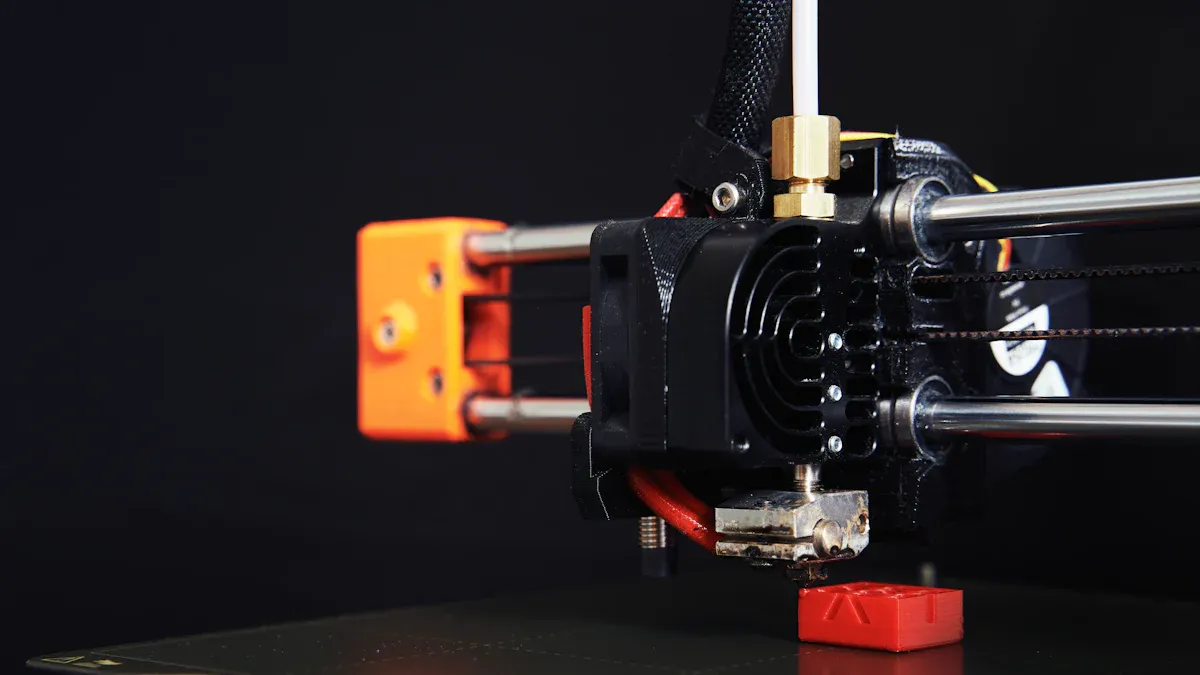

Practical Steps to Upgrade Existing Twin Screw Plastic Extruders

Upgrading existing Twin Screw Plastic Extruder systems requires careful planning. Manufacturers should first assess the current condition of their equipment. They need to identify which components would benefit most from CNC machining or nitriding treatment.

Cost considerations play a major role in upgrade decisions. The size of the extruder, material costs, and manufacturing complexity all affect the total investment. Small extruders have lower material costs and simpler manufacturing needs. Medium and large extruders require more resources and advanced technology, which increases costs.

| Extruder Size | Material Costs | Manufacturing Complexity |

|---|---|---|

| Small | Low | Simple |

| Medium | Moderate | Moderate |

| Large | High | Complex |

Manufacturers should also consider material compatibility and production capacity. Different extruders handle various materials, which can affect upgrade costs. High-capacity operations may need advanced features, such as automation and energy-efficient systems. While these features increase initial costs, they often lead to long-term savings through reduced maintenance and energy use.

- Material compatibility affects upgrade costs.

- Production capacity determines the need for high-capacity extruders.

- Technological features, such as automation and energy efficiency, require higher initial investments but offer long-term savings.

Tip: Partnering with experienced manufacturers, such as Zhejiang Jinteng Machinery Manufacturing Co., Ltd., ensures access to advanced CNC and nitriding technology. Their expertise helps streamline the upgrade process and maximize equipment performance.

By following these steps, manufacturers can modernize their Twin Screw Plastic Extruder systems, improve efficiency, and extend equipment life.

Manufacturers achieve higher efficiency and sustainability by upgrading extruders with CNC and nitriding technology. The table below highlights long-term benefits:

| Benefit | Description |

|---|---|

| High Production Efficiency | Enhances efficiency, extends service life, and increases continuous working time of machines. |

| Consistency and Precision | Produces parts with tight tolerances and high dimensional accuracy for consistent production. |

| Cost-Effectiveness | Minimizes material waste, reduces scrap, and increases material utilization. |

Next steps: Invest in advanced technologies, focus on eco-friendly materials, and train operators for optimal system performance.

FAQ

What benefits does CNC technology bring to twin screw extruder upgrades?

CNC technology ensures precise manufacturing. It improves part consistency and reduces waste. Manufacturers achieve higher efficiency and better product quality with CNC upgrades.

How does nitriding extend the life of extruder screws and barrels?

Nitriding creates a hard surface layer. This layer resists wear and abrasion. Equipment lasts longer and requires less frequent replacement.

Can existing extruders be upgraded with CNC and nitriding technology?

Yes. Manufacturers can retrofit current systems. Upgrades improve performance, increase durability, and reduce maintenance costs.

Tip: Consult with experienced manufacturers for the best upgrade solutions tailored to specific production needs.

Post time: Sep-02-2025