Single screw barrels play a huge role in many industries today. Companies in plastics manufacturing, food processing, the rubber industry, chemical processing, pharmaceuticals, recycling, and cable and wire manufacturing use them every day. The market for screw barrel for single screw extruder products keeps growing. In 2023, the global market reached USD 1.5 billion, with a projected value of USD 2.1 billion by 2032.

Here’s a quick look at the numbers driving this growth:

| Metric | Value | Notes |

|---|---|---|

| Market Size (2023) | USD 1.5 billion | Global bimetallic barrel and screw market including single screw barrels |

| Projected Market Size (2032) | USD 2.1 billion | Forecasted market value |

| Compound Annual Growth Rate | 3.8% | CAGR during forecast period |

| Key Industries Driving Growth | Plastic processing, consumer goods, packaging, automotive | Industries heavily reliant on single screw barrels due to demand for plastic products |

| Regional Growth Focus | Asia Pacific | Driven by rapid industrialization and urbanization |

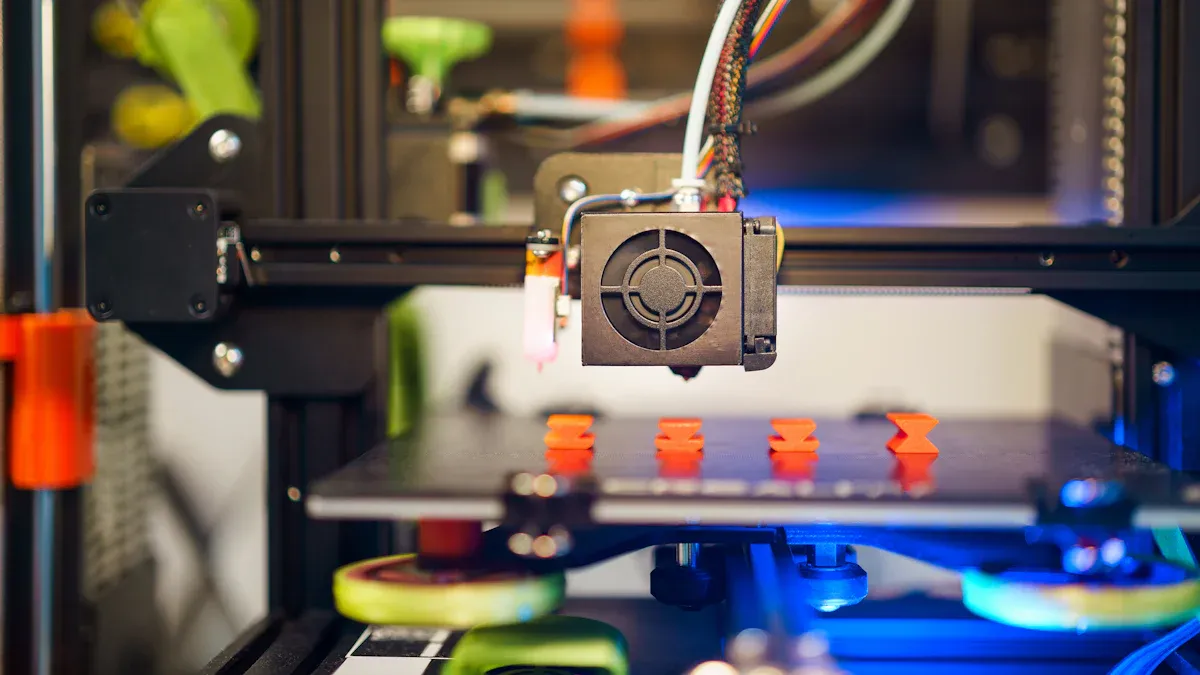

Single Plastic Screw Barrel Factory teams stay busy as single screw barrels remain popular for their reliability and efficiency.

Single Screw Barrel in Plastics Manufacturing

Key Applications

Single Screw Barrel technology stands at the heart of plastics manufacturing. Companies use these barrels for many tasks, such as:

- Melting and conveying different types of polymers, including PVC, PE, and ABS.

- Producing pipes, films, sheets, and profiles for construction, packaging, and automotive industries.

- Handling non-homogeneous blends and recycled plastics with steady pressure and heat.

- Supporting both basic extrusion and advanced processes like film blowing and profile shaping.

Barrels often use high-performance materials like 38CrMoAlA and bimetallic alloys. These materials help the barrels resist high temperatures, pressure, and wear. Surface treatments, such as nitriding and chromium-plating, extend the lifespan and improve performance.

Why Single Screw Barrels Are Essential

The Single Screw Barrel brings several advantages to plastics manufacturing. The table below highlights some important features and their impact:

| Aspect | Details and Benefits |

|---|---|

| Diameter | 16 mm to 300 mm, fits many production scales |

| Aspect Ratio (L/D) | 15 to 40, boosts melting and mixing efficiency |

| Material | Durable steel, resists wear and corrosion |

| Surface Hardness | High hardness, long-lasting with special surface treatments |

| Structure | Simple design, easy to maintain, cost-effective |

These barrels control temperature, flow, and pressure during extrusion. They help create products with consistent quality. Their simple structure means fewer breakdowns and lower costs. Many factories choose them for their reliability and flexibility.

Notable Examples and Trends

Mixing and process control have become key trends in plastics manufacturing. For example, a Maddock solidification experiment showed how mixing starts in the melting zone of a single screw extruder. In another case, companies used single screw barrels to make Nylon-6 filaments with metallic powders. They adjusted screw speed, die temperature, and other settings to get strong, uniform filaments. Over time, single screw extruders have evolved from simple pumps to advanced machines with special mixing sections and improved barrel designs. These changes help factories meet new demands for quality and efficiency.

Single Screw Barrel in Food Processing

Key Applications

Single screw barrels help food companies make many popular products. They work best with foods that have simple recipes and need steady processing. Here’s a quick look at where they shine:

| Food Product Category | Single Screw Barrel Application | Reason for Suitability |

|---|---|---|

| Direct-expanded snacks | Yes | Cost-effective, simple formulations |

| Pasta and noodles | Yes | Traditional dough processing, low moisture |

| Breakfast cereals | No | Requires better shape control, multiple feeds |

| Protein products (e.g., TVP) | No | Requires superior texture and ingredient control |

| Pet food | Sometimes | Used for simpler kibble, but twin-screw preferred for uniformity |

Food makers also use single screw barrels for puffed soybeans, rice hulls, and animal feed. These machines can process ingredients like maize starch, cake meals, and even fish meal. They help improve shelf life and make food safer for animals and people.

Why Single Screw Barrels Are Essential

Single screw barrels play a key role in food safety and quality. Scientific studies show that these machines can lower harmful toxins in grains by controlling moisture, feed rate, and screw speed. This means safer flour and snacks for everyone. Food factories rely on single screw barrels to mix, cook, and shape food. They can add new ingredients and change textures, making it easier to create tasty snacks, pasta, and pet food. Companies also like them because they use less energy and are easy to maintain.

Note: Single screw barrels help food companies save money while making safe, high-quality products.

Notable Examples and Trends

Food processing keeps changing, and single screw barrels help lead the way. These machines use heat and pressure to break down starch and proteins. This makes food easier to digest and gives it the right shape and texture. For example, higher barrel temperatures help starch cook better, while screw speed changes how smooth or crunchy the final product feels. Newer machines let companies control heat and speed more closely, so they can make fish feed pellets and snacks that always look and taste the same. This level of control helps food makers meet new trends and customer needs.

Single Screw Barrel in Rubber Industry

Key Applications

Single screw barrels help rubber factories make many important products. These machines handle tough, sticky rubber materials and turn them into useful shapes. Here are some main uses:

- Making seals and gaskets for cars and machines

- Producing hoses for vehicles, factories, and homes

- Creating rubber sheets and profiles for building and industry

- Using vented barrels to remove moisture and keep rubber pure

Rubber extrusion takes up about 30% of the feed screw barrel market. This shows how important these machines are for the rubber industry. Companies often choose bimetallic barrels because they last longer and work better with rough rubber compounds.

Why Single Screw Barrels Are Essential

Factories rely on single screw barrels to keep rubber products strong and reliable. These machines melt, mix, and shape rubber with steady pressure and heat. Newer barrels use special materials like nitride steel. This makes them tough and helps them last longer, even when working with hard or gritty rubber. The Asia Pacific region, especially China and Southeast Asia, leads the world in using these machines. Rapid growth in these areas means more demand for strong, high-quality rubber products. Companies also follow strict quality rules, like ISO 9001, to make sure every product meets high standards.

Notable Examples and Trends

The rubber industry has used single screw barrels for over a century. Early machines worked like pumps, but inventors soon added features to mix rubber better. In the 1920s and 1930s, engineers created barrels with serrated surfaces to improve mixing. After World War II, new designs included special mixing sections and pins inside the barrel. These changes helped factories make better rubber products, faster and with less waste. Today, companies keep improving single screw barrel designs to meet new needs in cars, construction, and industry.

Single Screw Barrel in Chemical Processing

Key Applications

Chemical processing plants use single screw barrels for many important jobs. These machines help make PVC pipes for construction, plumbing, and electrical conduits. Factories also use them for industrial piping, irrigation systems, and even food and beverage transport. Here are some key uses:

- Extruding PVC pipes for building and industry

- Making pipes for automotive fluid transfer

- Producing chemical-resistant pipes for agriculture and food processing

- Handling tough materials with abrasive fillers and additives

Engineers choose high-strength alloy steel for these barrels. They treat the surface to make it extra hard, so it can handle high temperatures and pressure. Heating and cooling systems keep the temperature just right. Sensors watch the process to make sure every pipe comes out strong and smooth. Many plants have cut their scrap rates by using real-time monitoring and better screw designs.

Why Single Screw Barrels Are Essential

Factories need single screw barrels because chemical processing can be tough on equipment. Abrasive fillers and corrosive polymers can wear down machines fast. The right screw and barrel design keeps everything running smoothly. Features like grooved feed sections and barrier mixing sections help melt and mix materials evenly. High compression ratios make sure the pipes come out strong and uniform. These design choices help prevent defects and keep waste low. Plants can use these barrels with many types of polymers, making them a flexible choice for different jobs.

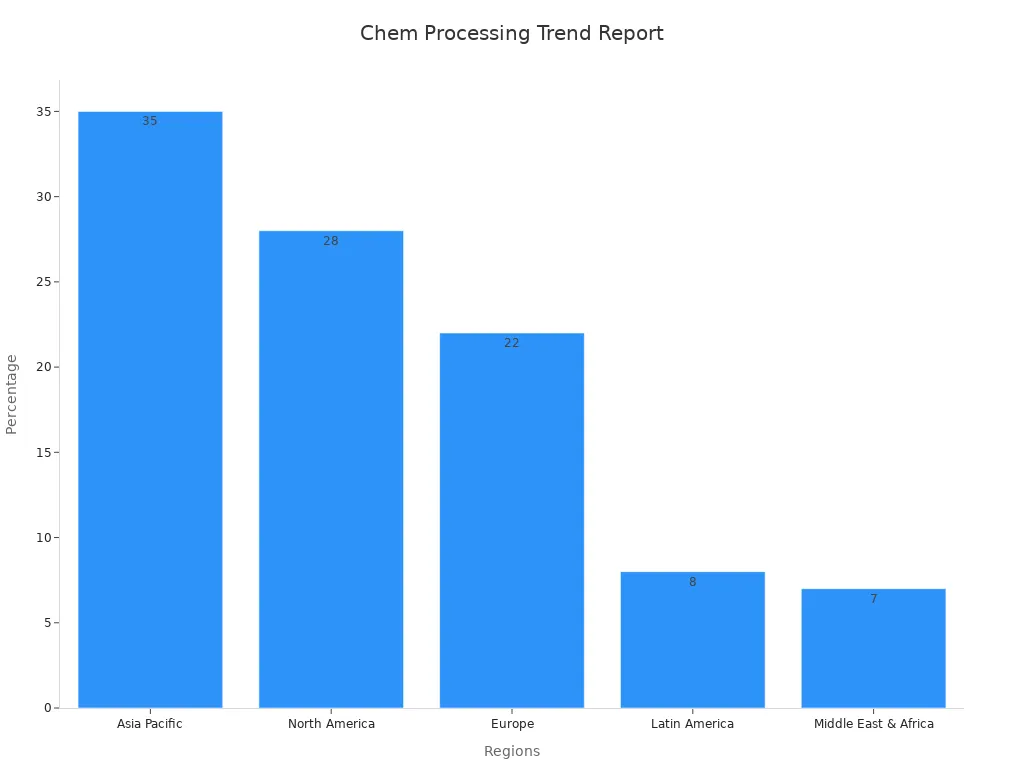

Notable Examples and Trends

Industry reports show that the single screw feed barrel market is growing fast. In 2024, this segment was valued at $840 million and could reach $1.38 billion by 2034. Companies want simple, reliable machines that work well with uniform materials. Automation, new materials, and eco-friendly solutions are driving growth. Factories now use smart technologies and IoT for real-time monitoring. High-performance alloys and composite coatings are becoming more popular. The chemical industry is one of the fastest-growing users of these barrels, especially in Asia Pacific and North America.

| Aspect | Details |

|---|---|

| Fastest Growing Application | Chemical Industry, driven by demand for plastic production and advanced materials |

| Key Trends | High-performance alloys, sustainability, cost-efficiency |

| Regional Contribution (2023) | Asia Pacific (35%), North America (28%), Europe (22%) |

| Technological Advances | Improved barrel design, wear resistance, IoT monitoring |

Single Screw Barrel in Pharmaceutical Industry

Key Applications

Pharmaceutical companies use single screw barrels in many important ways. These machines help turn powders and mixtures into solid forms like rods, tubes, or thin films. The process is called hot-melt extrusion. It uses a rotating screw inside a barrel to heat and push the material forward. This method works well for making medicine implants, controlled-release tablets, and drug delivery films.

- Single screw extruders shape drug and carrier materials into uniform products.

- The machines have electronic controls for screw speed, temperature, and pressure.

- Companies can adjust the screw length-to-diameter ratio to change how the material melts and mixes.

This technology helps companies move from small lab batches to large-scale production without losing quality.

Why Single Screw Barrels Are Essential

Single screw barrels are vital in pharmaceutical manufacturing. They keep the material moving smoothly and help mix drugs with other ingredients. The right amount of friction between the screw and barrel melts the material and keeps the process steady. Clean barrels and screws prevent leftover material from causing problems or mixing with new batches. This is very important for medicine safety.

Pharmaceutical companies choose barrels made from strong, corrosion-resistant materials. These barrels can handle harsh chemicals and gritty powders. Regular cleaning and careful maintenance help keep the machines running well and avoid costly downtime.

Tip: Keeping the screw and barrel clean helps prevent contamination and ensures every batch of medicine meets strict quality standards.

Notable Examples and Trends

Pharmaceutical companies often use single screw barrels for continuous production. This method helps them make medicine faster and with fewer mistakes than old batch processes. The machines have different zones inside the barrel for feeding, compressing, and shaping the material. Companies can change the screw design to fit different products.

- Single screw extruders work best for making solid drug forms that need steady pressure and heat.

- Many companies now use computer models to test how powders move through the screw. This helps them find the best settings for each product.

- The industry is moving toward more continuous processes, using single screw barrels to improve quality and lower costs.

Single Screw Barrel in Recycling Industry

Key Applications

Recycling plants use single screw barrels to turn old plastic into new products. These machines handle many types of plastics, like PE, PP, PVC, and PET. They melt, mix, and shape recycled plastic into pellets or films. Engineers design these barrels with strong materials, such as 38CrMoAl, and treat the surface to make them last longer. Some barrels have special coatings that help them resist wear from rough recycled materials.

Here are some main uses:

- Making plastic pellets for new products

- Producing recycled plastic films and sheets

- Handling foams, fibers, and even plastic bottles

A table below shows some technical features:

| Feature | Details |

|---|---|

| Diameter | 60-300mm |

| L/D Ratio | 25-55 |

| Surface Hardness | HV≥900 (nitriding) |

| Applications | Granulation, film, and sheet production |

Why Single Screw Barrels Are Essential

Single screw barrels play a big role in recycling. They keep the process steady and help control the quality of recycled plastic. Scientists have found that these machines work well with regrind and recycled polymers. The design of the barrel and screw lets factories process many kinds of plastics without losing quality. When the barrel and screw heat up, they expand at the same rate, which keeps everything running smoothly. This is important for making sure the melted plastic flows evenly and the final product stays strong.

Note: Barrels made for recycling often use advanced materials and coatings. This helps them last longer, even when working with tough, dirty plastics.

Notable Examples and Trends

Many recycling companies choose single screw extruders because they cost less and work well with stable plastic waste. Some systems, like the Erema Corema, use a single screw extruder to melt and filter recycled plastic before sending it to a twin-screw extruder for extra mixing. This setup helps make recycled plastic stronger and more useful.

Recent trends include:

- Using smart technology to monitor and control the recycling process

- Developing barrels with modular designs for different recycling needs

- Combining single and twin-screw extruders for better results

Single screw barrels remain a top choice for recycling because they are reliable, flexible, and help support a circular economy.

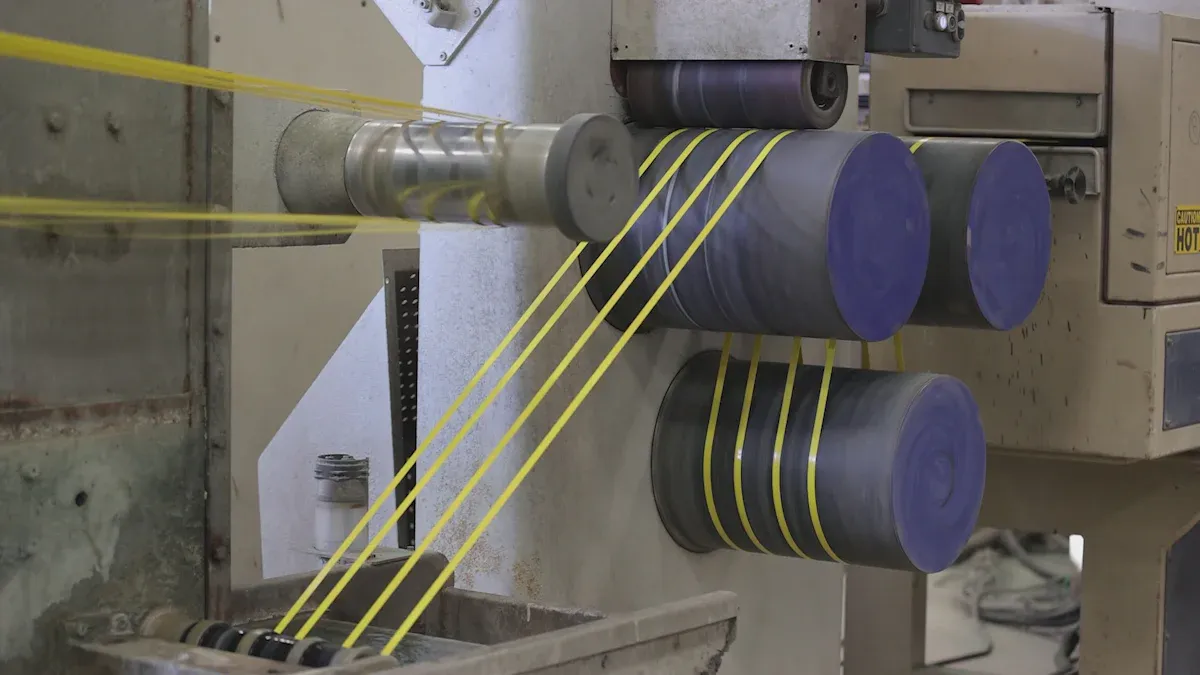

Single Screw Barrel in Cable and Wire Manufacturing

Key Applications

Cable and wire factories use single screw barrels to coat wires with plastic. These machines melt plastic pellets and push the melted material around the wire. The process creates a smooth, even layer that protects the wire and keeps electricity flowing safely. Many companies use these machines to make insulation and outer sheaths for power cables, data cables, and telephone wires.

Here is a table showing important technical details:

| Aspect | Details |

|---|---|

| Application | Extrusion of insulating and protective layers around electrical wires and cables |

| Key Performance Features | Consistent coating thickness, dielectric properties |

| Screw Type | Single helical screw for melting and pushing plastic |

| Materials Used | Hardened steel, bimetallic alloys, nitrided steel, tungsten carbide coatings |

| Barrel Features | High-strength, heat-resistant materials, external heaters, temperature sensors |

Why Single Screw Barrels Are Essential

Single screw barrels help cable makers work faster and save money. The simple design makes them easy to use and fix. Workers can change the screw or barrel quickly if needed. The machines keep the plastic hot and flowing smoothly, so every cable gets a strong, even coating. The process uses less energy and gives better control over the thickness of the plastic layer. This helps companies meet safety rules and make high-quality products.

Tip: Single screw barrels are perfect for continuous production. They keep the process steady and reduce waste.

Notable Examples and Trends

Many companies choose single screw extruders for cable and wire because they are reliable and cost-effective. For example, Milacron extruders use strong gear systems and special coatings to last longer. Some machines have automatic controls that adjust heat and speed for each job. New designs focus on faster die changes and better heat transfer. These trends help factories make more cables in less time and with fewer mistakes.

Comparative Summary of Single Screw Barrel Applications

Unique Uses by Industry

Each industry uses screw barrels in its own way. For example, plastics factories rely on these machines to melt and shape materials like polyethylene and polypropylene. A case study from a blown film production line showed that screw wear can lower output from 130 kg/hr to 117 kg/hr. This drop led to a yearly loss of about 79,000 kg. When engineers improved the screw design, they not only fixed the problem but also increased production above the original rate. This shows how much performance matters for profits.

Here’s a quick look at how different industries use screw barrels:

| Industry | Unique Use | Market Growth Forecasts |

|---|---|---|

| Plastics | Melting and forming thermoplastics (PE, PP) | CAGR of 4-5% through 2030 |

| Food Processing | Making snacks and cereals | Market to exceed $75 billion by 2026 |

| Rubber Compounding | Mixing and shaping rubber for tires and auto parts | Tire production to surpass 2 billion units by 2025 |

| Biomedical | Creating biopolymers for packaging and medical devices | Fast-growing with new technology |

Overlapping Applications

Many industries share similar needs when it comes to screw barrels. The basic design works for plastics, food, rubber, and even chemicals. This wide use started back in 1935, when Paul Troester invented the first single-screw extruder in Germany. Over time, experts like Darnell and Mol studied how these machines move solids and melt materials. Their models, first made for plastics, now help with powders, pastes, and even starch.

The main parts—solids conveying and melt zones—work the same way for many materials. Engineers use the same ideas for making pipes, snacks, or rubber sheets. Experiments with starch powder proved that the models fit many products. This shared foundation explains why so many factories choose screw barrels for different jobs.

Single Screw Barrel technology shapes many industries today. It helps companies make better products faster. Experts see new trends coming soon:

- AI and IoT make machines smarter.

- Factories use more green materials.

- Companies form new partnerships. These changes promise even higher quality and efficiency.

FAQ

What is a single screw barrel used for?

A single screw barrel melts, mixes, and pushes materials like plastic, rubber, or food through a machine. Many factories use it to shape products.

How often should a factory replace a single screw barrel?

Most factories check barrels every year. They replace them when they see wear or a drop in product quality.

How does someone choose the right single screw barrel?

They look at the material, product type, and machine size. Experts help match the barrel to the job for best results.

Post time: Jun-17-2025