When I notice visible surface damage, recurring blockages, or inconsistent product quality in my Parallel Twin Screw Barrel For Extruder, I know it is time to consider replacement. Early detection saves costs and keeps production running smoothly. I always check my Twin Plastic Screw Barrel, Conical Twin Screw Twin Screw, and Twin Screw Extruder Barrels for these warning signs.

Excessive Wear in Parallel Twin Screw Barrel For Extruder

Visible Surface Damage

When I inspect my Parallel Twin Screw Barrel For Extruder, I look for clear signs of surface damage. I often see deep grooves on the screw elements, sometimes reaching up to 3 mm. Severe mechanical damage on the barrel’s inner surface stands out right away. I also check for cracks at the screw shaft tip and any damage to the visco-seal ring. Sometimes, I notice abnormal vibrations before a failure. These warning signs tell me that the barrel or screws may need replacement soon.

- Severe mechanical damages inside the barrel

- Deep grooving on screw elements (up to 3 mm)

- Clearance from wear, sometimes as much as 26 mm

- Cracks at the screw shaft tip or damaged visco-seal ring

- Unusual vibration levels before failure

Barrel Diameter Changes

I always measure the barrel diameter to check for wear. Industry standards suggest that the acceptable wear tolerance for the barrel is between 0.1 and 0.2 mm (0.004 to 0.008 inches). If I see the diameter has changed beyond these limits, I know the barrel is worn out. Here’s a quick reference:

| Component | Wear Tolerance (mm) | Wear Tolerance (inches) |

|---|---|---|

| Screw | 0.1 | 0.004 |

| Barrel | 0.1 to 0.2 | 0.004 to 0.008 |

Increased Screw-to-Barrel Clearance

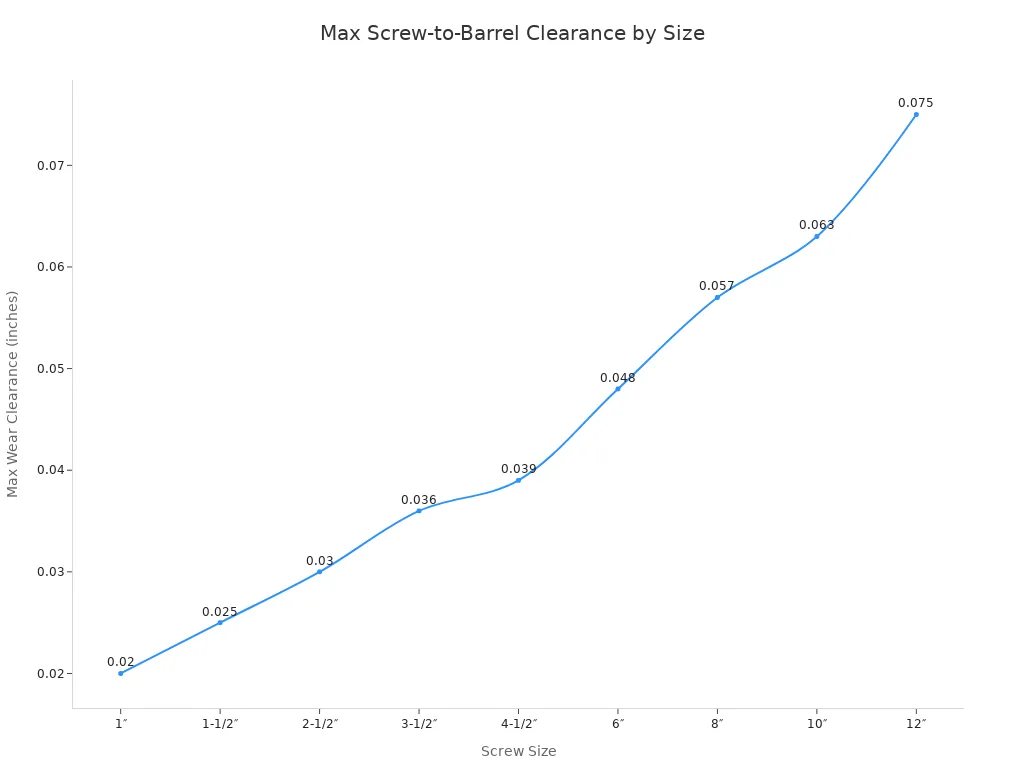

I pay close attention to the gap between the screw and the barrel. If this clearance grows too large, problems start to appear. The chart below shows the maximum recommended clearances for different screw sizes:

When the gap increases, I notice more backflow and leakage of plastic. This causes pressure and volume to fluctuate. The plastic can overheat, which hurts product quality. I often need to increase the machine’s speed and energy use just to keep up. A small gap keeps everything sealed and efficient, but a large gap leads to leaks and lower output. If I see these issues, I know my Parallel Twin Screw Barrel For Extruder needs attention.

Reduced Efficiency of Parallel Twin Screw Barrel For Extruder

Lower Output Rates

When my extruder’s performance drops, I notice it right away. The machine produces less material in the same amount of time. I check the Parallel Twin Screw Barrel For Extruder for signs of wear. Worn screws or barrels slow down the movement of plastic. This means I get fewer finished products each hour. Sometimes, I see the hopper stays full longer than usual. This tells me the machine cannot keep up with demand.

Inconsistent Product Quality

I always watch for changes in the quality of my products. If I see rough surfaces or uneven shapes, I know something is wrong. Worn barrels and screws can cause poor mixing and uneven melting. This leads to problems like melt fracture or die build-up. Here is a table that shows common product quality issues linked to barrel wear:

| Product Quality Issue | Description |

|---|---|

| Excessive Wear and Tear | Leads to reduced output, inconsistent mixing, and increased maintenance costs. |

| Melt Fracture | Results in rough or irregular surface, affecting appearance and mechanical properties. |

| Die Build-Up | Causes poor surface quality and dimensional inconsistencies due to polymer degradation. |

When I see these problems, I know it is time to inspect the barrel and screws.

Increased Energy Consumption

I pay close attention to my energy bills. When the extruder uses more power than before, I know efficiency has dropped. Worn screw elements force the machine to work harder. This increases energy use and costs. I always inspect the screws and barrel when I see a spike in energy consumption. Replacing worn parts helps restore optimal operation and saves money.

Frequent Maintenance and Repair Issues

Recurring Blockages or Jams

I often face blockages or jams in my extruder when the system is not running smoothly. Several factors can cause these issues:

- Reversing kneading blocks sometimes create high-pressure zones, which lead to compaction and blockages.

- Excessive clearance between the screw and barrel allows material to flow backward, causing volume changes and jams.

- Worn screw flights or scratches inside the barrel disrupt the mixing process. This results in unmelted particles and uneven material thickness.

- If the screw design does not match the material properties, I see sudden load increases or even material stagnation, which can stop production.

When I notice these problems, I know my equipment needs attention.

Unusual Noises or Vibrations

Strange noises or vibrations always catch my attention during operation. These sounds often signal deeper problems. I have learned to watch for the following:

| Type of Failure | Cause | Performance |

|---|---|---|

| Bearings damaged | Long-term use, poor lubrication, overload, or improper installation | Increased vibration and noise, unstable screw rotation, possible screw misalignment |

| Gearbox failure | Wear, lack of lubrication, oil contamination, or excessive load | Gear noise, high oil temperature, lower efficiency, risk of gear breakage |

Sometimes, I also hear odd sounds from misalignment, broken bearings, or even foreign objects inside the barrel. These signs tell me to stop and inspect the Parallel Twin Screw Barrel For Extruder right away.

Higher Frequency of Repairs

When I find myself repairing the extruder more often, I know something is wrong. Frequent repairs mean the system is wearing out. I track how often I replace parts or fix jams. If the repair schedule becomes shorter, I consider replacing the barrel or screws. This helps me avoid bigger failures and keeps my production line running smoothly.

Material Leakage or Contamination in Parallel Twin Screw Barrel For Extruder

Signs of Leakage Around Barrel

When I run my extruder, I always check for leaks around the barrel. Leaks can signal bigger problems inside the machine. I often see small pools of molten material near the exhaust port or along the barrel joints. Sometimes, I notice a burning smell or smoke, which tells me material is escaping where it should not.

Several issues can cause these leaks:

- Material backflow from an unreasonable screw design

- Poor exhaust port or vent design that traps molten material

- Mechanical wear that increases the gap between the screw and barrel

- Improper temperature control, which can overheat and damage the barrel

- Processing abrasive materials or running the machine for long periods, which increases wear

- Lubrication problems that raise friction and cause more wear

If I spot any of these signs, I know my Parallel Twin Screw Barrel For Extruder needs a closer look.

Contaminants in Final Product

I always inspect my finished products for signs of contamination. When the barrel wears out or fails, I often see changes in the product’s appearance and strength. The table below shows some common problems and what they look like:

| Issue | Effect on Product Quality | Visual Signs |

|---|---|---|

| Surface Delamination | Weak layers, peeling, or flaking | Peeling or flaking on the surface |

| Discoloration | Color streaks, abnormal patches, reduced strength | Streaks or odd color spots |

| Splay Marks | Brittle parts, poor impact resistance, surface marks | Silvery or cloudy streaks |

When I see these defects, I know contamination or wear inside the barrel is likely the cause. I act quickly to prevent more damage and keep my products at a high standard.

Obsolescence and Compatibility Challenges

Outdated Barrel Design

I often see older extruders struggle to keep up with new production demands. When I use an outdated barrel design, I notice it cannot handle the latest materials or deliver the same efficiency as modern equipment. Over the past decade, manufacturers have made big improvements in parallel twin screw barrels. These advancements help me process more types of plastics and additives. I rely on the latest designs to boost output and improve product quality. Here is a table that shows some of the most important changes:

| Advancement | Impact on Performance |

|---|---|

| Enhanced material processing range | Ability to process highly viscous and complex materials |

| Higher output rates | Increased production rates compared to single-screw extruders |

| Reduced thermal degradation | Shorter residence time leading to better material quality |

| Modular designs | Improved mixing efficiency and operational flexibility |

When I compare my old equipment to these new features, I see how much I miss out on by not upgrading.

Incompatibility with New Materials or Processes

I often need to work with new polymers or additives. Sometimes, my older Parallel Twin Screw Barrel For Extruder cannot handle these changes. I see poor mixing, uneven melting, or even machine jams. Newer barrels use modular screw elements and better temperature control. These features let me switch materials or change processes quickly. If my barrel cannot keep up, I risk losing business or falling behind competitors. I always check if my equipment matches the latest industry needs before starting a new project.

Inspection and Monitoring Tips for Parallel Twin Screw Barrel For Extruder

Routine Visual Checks

I always start my day with a careful walk around my extruder. I look for cracks in the barrels or dents in the frame. I check for loose bolts and tighten them right away to stop vibrations. I make sure the lubrication system is full and look for leaks. I also inspect the cooling system to see if the coolant level and flow are correct. I check all electrical connections to make sure they are secure and undamaged. I look at the screws for signs of wear or dirt. The flight tips should stay sharp, and there should not be too much space between the screw and the barrel. If I see scratches or corrosion inside the barrel, I fix the problem before starting production.

Tip: I always address any leaks in hoses or pipes quickly to avoid wasting material.

Measuring Wear and Tolerances

I use precision tools to measure the barrel diameter and screw-to-barrel clearance. I compare my measurements to the recommended tolerances. If I see the barrel diameter or the gap has grown too large, I know it is time to plan for maintenance or replacement. I keep a log of these measurements so I can spot changes over time. This helps me catch problems early and keep my Parallel Twin Screw Barrel For Extruder running smoothly.

Consulting Manufacturer Guidelines

I always read the manufacturer’s manual before making any changes. The manual gives me the correct tolerances, maintenance schedules, and inspection steps. I follow their advice for cleaning, lubrication, and part replacement. If I have questions, I contact the manufacturer for support. This helps me protect my equipment and keep my production line safe.

Making the Replacement Decision

Cost-Benefit Analysis

When I decide whether to replace my Parallel Twin Screw Barrel For Extruder, I always start with a cost-benefit analysis. I look at several important factors that affect my bottom line. I want to make sure my investment pays off in the long run. Here is a table that helps me compare the main points:

| Factor | Description |

|---|---|

| Energy Efficiency | Energy savings lead to long-term cost reductions, enhancing competitiveness in the industry. |

| Equipment Lifespan | Robust design and durable components extend the lifespan of screws and barrels, reducing replacement costs. |

| Maintenance Costs | Regular maintenance can reduce downtime and avoid costly emergency repairs, impacting overall costs. |

| Quality Consistency | Consistent quality prevents product defects and regulatory issues, which can incur additional costs. |

| Operational Efficiency | Improved efficiency reduces energy consumption and increases throughput, affecting overall profitability. |

I review each factor and ask myself if the current barrel meets my needs. If I see rising energy bills or frequent repairs, I know it is time to act. Consistent product quality also matters. If I notice defects, I consider the cost of lost sales and customer complaints. By weighing these points, I make a smart decision for my business.

Timing Replacement to Minimize Downtime

I always plan my replacement to keep downtime as low as possible. I schedule the work during slow production periods or maintenance windows. Careful timing helps me avoid lost revenue and keeps my team productive. I use a table to track the benefits of good planning:

| Benefit | Percentage Reduction |

|---|---|

| Waste rates | 12–18% |

| Energy costs | 10% |

| Downtime | up to 30% |

When I replace the barrel at the right time, I see less waste and lower energy costs. My team finishes the job faster, and production starts up again quickly. I always communicate with my staff and suppliers to make sure everything runs smoothly. Good timing protects my profits and keeps my customers happy.

I always watch for these signs in my parallel twin screw barrel for extruder:

- I monitor the wear gap; repairs work up to 0.3mm, but I replace the barrel if the gap grows or the nitriding layer fails.

- I weigh repair costs against replacement and track wear to avoid downtime.

- I inspect my equipment every 500–1,000 hours.

- Routine checks help me catch problems early.

Regular monitoring keeps my production efficient and saves money.

FAQ

How often should I inspect my parallel twin screw barrel for wear?

I check my barrel every 500 to 1,000 operating hours. Regular inspections help me catch problems early and keep my extruder running smoothly.

Tip: I always log inspection results for future reference.

What is the maximum screw-to-barrel clearance before replacement?

I replace the barrel when the screw-to-barrel gap exceeds 0.3 mm. This prevents leaks and keeps product quality high.

| Component | Max Clearance (mm) |

|---|---|

| Screw-to-Barrel | 0.3 |

Can I repair a worn barrel instead of replacing it?

I repair minor wear up to 0.3 mm. If the nitriding layer fails or damage is severe, I choose replacement for better performance.

Post time: Aug-28-2025