Manufacturers and buyers recognize the conical twin screw barrel for SPC floor as a leading choice in 2025. Selecting the right Twin Screw Extrusion Machine affects product quality, mixing efficiency, and operational costs. The Injection Molding Machine Screw Barrel and Twin Screw Extrusion process play vital roles in handling PVC’s thermal sensitivity, ensuring consistent results.

Conical Twin Screw Barrel for SPC Floor: Direct Answer

Is the Conical Twin Screw Barrel Superior in 2025?

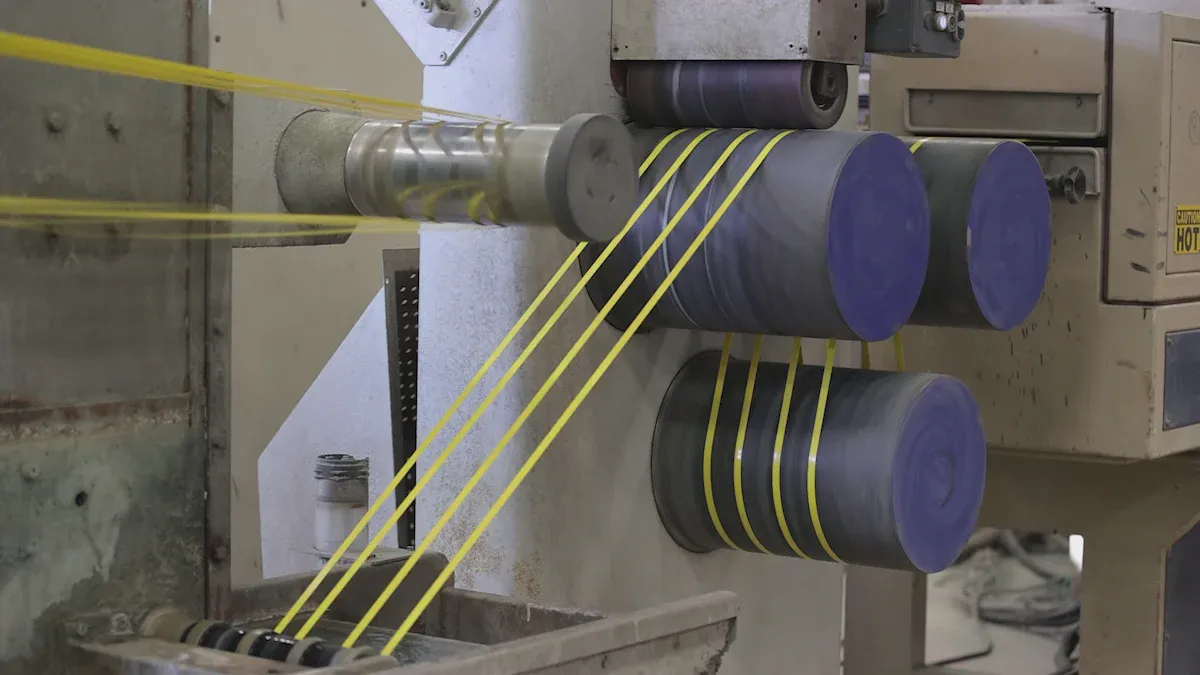

Industry experts agree that the conical twin screw barrel for SPC floor stands out as the preferred choice in 2025. This barrel design features a gradually decreasing diameter and a controlled compression ratio. These features build pressure that is ideal for melting PVC, which ensures uniform gelation without causing excessive heat. Manufacturers benefit from high wear resistance because the barrel uses high-strength alloy steels treated by nitriding or bimetallic linings. This durability is essential for handling abrasive fillers in PVC compounds.

The conical twin screw barrel for SPC floor also provides enhanced venting and mixing sections. These sections remove trapped air and blend colorants and modifiers thoroughly. This process prevents defects such as undispersed pigments or overheating. The barrel achieves better homogeneity of the melt and superior feeding of powders compared to other screw types. Multi-zone heating and cooling in the barrel allow precise temperature control, which maintains ideal melt viscosity and product quality. Local stock availability supports fast delivery and reduces downtime, helping manufacturers maintain continuous production.

Key Factors Driving the Choice

Several factors drive the adoption of conical twin screw barrels in SPC flooring production. The global market trends show a strong demand for efficient, continuous processing with superior mixing and compounding capabilities. These trends directly benefit SPC flooring manufacturing. Technological advancements in automation and energy efficiency encourage manufacturers to choose sophisticated extrusion equipment like the conical twin screw barrel for SPC floor.

Rapid industrialization in Asia-Pacific and North America increases the need for advanced extrusion systems. Government initiatives and infrastructure development boost demand for high-performance machinery. Regulatory standards related to environmental compliance and product quality push manufacturers toward eco-friendly twin screw extruders. The SPC flooring market grows quickly because buyers want durable, cost-effective, and water-resistant flooring solutions. Manufacturers respond by adopting advanced extrusion technologies that offer precise mixing and compounding capabilities.

Urbanization and construction growth in emerging markets require scalable and efficient production methods. Modern twin screw extruders meet these needs by providing customization and high-performance materials. Sustainability and regulatory trends further promote the use of eco-friendly and compliant machinery. Regional growth and the need for high-quality products reinforce the importance of choosing the conical twin screw barrel for SPC floor in 2025.

Conical vs. Parallel Twin Screw Barrels: What Sets Them Apart?

Design and Structure Differences

The design of twin screw barrels plays a critical role in SPC flooring production. Parallel twin screw barrels use two screws with a uniform diameter along their length. These screws rotate side by side and provide a steady flow of material. In contrast, conical twin screw barrels feature screws that gradually decrease in diameter. This unique shape brings the screws closer together at one end, creating specialized mixing zones.

The table below highlights the main differences:

| Feature/Aspect | Parallel Twin Screw Barrel | Conical Twin Screw Barrel |

|---|---|---|

| Screw Diameter | Uniform along length | Gradually decreases |

| Screw Orientation | Side by side, parallel | Closer together, angled |

| Mixing Zones | Basic, paddle-style flights | Specialized for thorough blending |

| Feeding Characteristics | Standard feeding | Enhanced feeding, efficient pre-processing |

| Pressure Stability | Less complex | Improved across mixing zones |

| Output Capability | High output | Moderate output, better control |

| Energy Efficiency | More efficient | Slightly higher consumption |

| Control and Automation | Basic controls | Advanced PLC, intelligent controls |

| Suitability for SPC Flooring | Best for simple, high-volume jobs | Best for complex, precise jobs |

Impact on SPC Flooring Production

The conical twin screw barrel for SPC floor offers several advantages in production. Its geometry ensures superior mixing and homogenization, which leads to fewer defects in the final product. The barrel maintains a more uniform temperature, improving melting and extrusion quality. Multiple heating zones allow precise control, resulting in consistent panel thickness and smooth surfaces.

Operators notice faster melting and plasticization, which reduces scrap rates and energy use. The advanced materials and surface treatments increase durability, leading to longer equipment life and less downtime. These features make the conical twin screw barrel for SPC floor an excellent choice for manufacturers who require high-quality, reliable SPC flooring output.

Advantages of Conical Twin Screw Barrel for SPC Floor

Pressure Generation and Material Handling

The conical twin screw barrel for SPC floor creates strong pressure during extrusion. This pressure helps melt PVC and other raw materials quickly. The barrel’s design moves materials smoothly from the feeding zone to the melting zone. Operators see fewer blockages and better control over the flow. The barrel handles powders and fillers with ease, reducing the risk of poor plasticization or uneven mixing.

Mixing Efficiency and Product Quality

Manufacturers rely on the conical twin screw barrel for SPC floor to achieve high mixing efficiency. The screws blend colorants, modifiers, and fillers evenly. This process prevents defects such as undispersed pigments or hollow particles. The barrel’s structure supports thorough blending, which leads to consistent product quality. SPC flooring panels show uniform thickness and smooth surfaces.

Tip: Regular monitoring of raw material quality and equipment wear helps prevent common issues like black spots, broken bars, and bridging in the hopper.

Energy Consumption and Operational Costs

The SZJZ-180 conical twin screw extruder model demonstrates high output capacity with lower energy costs. Manufacturers produce 80-100 tons of SPC flooring daily while using less electricity than other extruder types. Twin screw extruders offer better throughput and mixing quality, which means improved energy utilization. Lower energy consumption reduces operational costs and supports sustainable production.

Maintenance and Longevity

Operators find that conical twin screw barrels require less frequent maintenance. The barrel uses high-strength alloy steels and advanced heat treatment. These features increase resistance to wear and corrosion. Equipment lasts longer and downtime decreases. Regular cleaning and inspection help maintain performance and extend service life.

- Common operational challenges include:

- Black spots from poor raw materials or overheating

- Broken bars due to impurities or weak shear

- Hollow particles from poor exhaust or low temperature

- False material issues from feeding speed mismatches

- Bridging problems from filler agglomeration or moisture

Manufacturers address these challenges by adjusting process parameters and maintaining equipment.

Disadvantages of Conical Twin Screw Barrel for SPC Floor

Production Scale Limitations

Manufacturers often choose equipment based on production needs. Conical twin screw barrels work best for medium-scale SPC flooring lines. Large factories may find that parallel twin screw barrels handle higher output more efficiently. Smaller workshops sometimes struggle to justify the investment in advanced conical systems. Production speed and batch size can limit the suitability of conical designs for every operation.

Material Compatibility Challenges

SPC flooring production uses a variety of raw materials. Some additives or fillers require special handling. Conical twin screw barrels perform well with standard PVC blends. However, unique or experimental compounds may not process as smoothly. Operators must test new materials before full-scale production. This step helps avoid unexpected issues during extrusion.

Note: Always consult with technical experts when introducing new materials to the extrusion process. Proper testing ensures consistent product quality.

Initial Investment and Cost Factors

The initial cost of a conical twin screw barrel system can be higher than other options. Precision engineering and advanced materials increase the price. Some manufacturers see this as a barrier, especially when starting new production lines. Ongoing maintenance costs remain low, but the upfront investment requires careful planning. Companies should evaluate long-term benefits against short-term expenses.

Practical Considerations for Choosing the Right Twin Screw Barrel

Matching Barrel Type to Production Needs

Manufacturers must consider several factors when selecting a twin screw barrel for SPC flooring production.

- Select barrel materials and coatings, such as nitriding or bimetallic layers, to improve wear resistance and extend service life.

- Choose the right barrel length-to-diameter (L/D) ratio. A higher ratio increases mixing and melting efficiency, which helps with high-output production.

- Ensure precise temperature control and mixing efficiency to keep melt temperatures steady and product quality consistent.

- Address wear and tear by using proper coatings and scheduling regular maintenance.

- Use barrels designed for high-filler content materials, like PVC with calcium carbonate, to prevent clogs and handle abrasive fillers.

- Customize barrel design to match the specific material formulation and production goals.

- Match screw and barrel specifications, such as diameter and L/D ratio, to the desired output and product quality.

Tip: Regular maintenance and careful adjustment of processing parameters help maintain stable production and reduce defects.

Cost-Effectiveness for Different Manufacturer Sizes

The cost-effectiveness of twin screw barrels depends on the size of the manufacturer. The table below shows how different models fit various production needs:

| Manufacturer Size | Extruder Model | Key Features | Output Capacity | Automation Level | Cost-Effectiveness Factors |

|---|---|---|---|---|---|

| Small (SMEs) | Base Model | Cost-efficient, standard PVC flooring | Lower output, basic automation | Minimal automation | Lower initial investment, fits limited production |

| Medium | Advanced Model | Higher output (~350 kg/h), semi-automation | Medium output | Semi-automated | Balances cost and productivity, ideal for mid-scale production |

| Large | Pro Model | Premium quality, full automation, advanced L/D ratio | High output (~500 kg/h) | Fully automated | Higher upfront cost, reduces defects by 40%, improves efficiency and quality |

Medium and large manufacturers benefit from advanced models with higher automation and output. Small businesses may prefer base models for their lower investment and simpler operation.

Material Flexibility and Compatibility

Material flexibility remains important in SPC flooring production. Manufacturers often use PVC mixed with high levels of calcium carbonate and other additives. Barrels must handle these abrasive fillers without excessive wear. Selecting the right coatings and steel types, such as 38CrMoAlA or SKD61, helps extend barrel life. Operators should monitor processing parameters like temperature, speed, and lubrication to maintain stable output and avoid defects. Using additives, such as ACR, supports plasticization and keeps the melt strong during rolling. Regular maintenance and careful adjustment of screw-barrel clearances ensure consistent product quality, even when using recycled materials or changing formulas.

The conical twin screw barrel for SPC floor remains a top choice in 2025. Experts highlight material selection, machine setup, and process optimization as key factors.

| Factor | Importance |

|---|---|

| Material selection | Prevents defects |

| Machine setup | Controls quality |

| Process optimization | Ensures smooth flow |

| Manufacturers should match equipment to their production needs. |

FAQ

What makes the conical twin screw barrel ideal for SPC flooring?

The conical design creates strong pressure and excellent mixing. This ensures uniform melting and high-quality SPC flooring panels every time.

How often should operators maintain the conical twin screw barrel?

Operators should inspect and clean the barrel regularly. Most manufacturers recommend maintenance every 1,000 production hours for best performance.

Can the conical twin screw barrel handle recycled materials?

Yes, the conical twin screw barrel processes recycled PVC blends efficiently. Operators should monitor material quality and adjust processing parameters for consistent results.

Tip: Always check raw material quality before starting production. This helps prevent defects and equipment wear.

Post time: Aug-22-2025