Injection screw barrels are at the heart of any injection molding process. Identifying damage quickly can save time and money. Signs like unusual noises or inconsistent product quality often mean trouble. Early detection matters. For example, a bimetallic injection screw and barrel, known for durability, can still wear out if used improperly. Regular checks help avoid costly downtime. A reliable barrel injection manufacturer can also offer guidance on maintenance and replacement options.

Common Signs of Damage in Injection Screw Barrels

Identifying damage in an injection screw barrel early can save time and money. Knowing what to look for helps operators act quickly. Here are some common signs that indicate trouble.

Visible Surface Damage

Surface damage is one of the easiest signs to spot. Scratches, dents, or grooves on the barrel’s interior can signal wear. These marks often appear when abrasive materials or contaminants pass through the system. Over time, this damage can worsen, affecting the barrel’s ability to process materials efficiently.

Operators should also check for discoloration or pitting. These issues may point to corrosion, especially if the barrel handles corrosive materials. Regular visual inspections can catch these problems before they escalate.

Tip: Use a flashlight to inspect the barrel’s interior for hard-to-see damage.

Performance Degradation

When an injection screw barrel starts to fail, performance takes a hit. Machines may struggle to maintain consistent melting or mixing. This leads to uneven product quality, which can frustrate customers and increase waste.

To better understand how damage impacts performance, consider the following metrics:

| Metric | Impact of Damage |

|---|---|

| Melting Efficiency | Decreases as clearances increase due to wear |

| Production Rate | May reach unacceptable levels due to wear |

| Scrap Rate | Increases as part quality diminishes with wear |

| Cycle Time | Increases as adjustments are made to compensate for wear |

These changes can disrupt production schedules and increase costs. Monitoring these metrics helps operators identify when a barrel needs attention.

Material Leaks or Build-Up

Material leaks or build-up around the barrel are clear signs of trouble. Leaks often occur when the barrel’s seals or clearances wear out. This can lead to wasted material and messy workspaces.

On the other hand, material build-up inside the barrel can block the flow of plastic. This issue usually happens when the barrel isn’t cleaned properly or when incompatible materials are used. Build-up can cause overheating, which may damage the barrel further.

Note: Addressing leaks or build-up quickly can prevent more severe damage and keep production running smoothly.

Causes of Damage in Injection Screw Barrels

Understanding what causes damage to an injection screw barrel can help operators take preventive measures. Here are the main culprits behind wear and tear.

Abrasive or Incompatible Materials

Materials that are too abrasive or incompatible with the barrel’s design can cause significant damage. For example, filled plastics or engineering plastics often contain hard particles that wear down the barrel’s surface over time. If the barrel isn’t made from a durable material like bimetallic alloys, it may struggle to handle these materials effectively.

Incompatible materials, such as PVC, require barrels with corrosion-resistant properties. Using the wrong type of barrel can lead to rapid deterioration. Operators should always match the barrel’s specifications to the materials being processed to avoid unnecessary damage.

Tip: Check the material’s compatibility with the barrel before starting production to prevent costly repairs.

Contamination and Foreign Particles

Contaminants and foreign particles in raw materials are another common cause of damage. Metal impurities or debris can scratch or gouge the barrel’s interior, reducing its efficiency. Low precision during manufacturing or inadequate heat treatment can also make the barrel more vulnerable to contamination.

To minimize this risk, operators should inspect raw materials for impurities before use. Regular cleaning of the barrel can also prevent build-up and contamination from affecting performance.

- Common contamination sources include:

- Metal matter in raw materials

- Impurities like dirt or dust

- Residual material from previous production cycles

Lack of Maintenance or Overuse

Neglecting routine maintenance or overusing the barrel can lead to premature wear. Prolonged operation without breaks increases the risk of overheating, which can weaken the barrel’s structure. Additionally, low temperatures during plasticization can cause uneven wear on the screw and barrel assembly.

Operators should follow a maintenance schedule to keep the barrel in optimal condition. This includes cleaning, lubrication, and checking for signs of wear. Overuse can be avoided by adhering to recommended operating times and ensuring the machine settings are optimized for efficiency.

Note: Regular maintenance not only prevents damage but also extends the lifespan of the injection screw barrel.

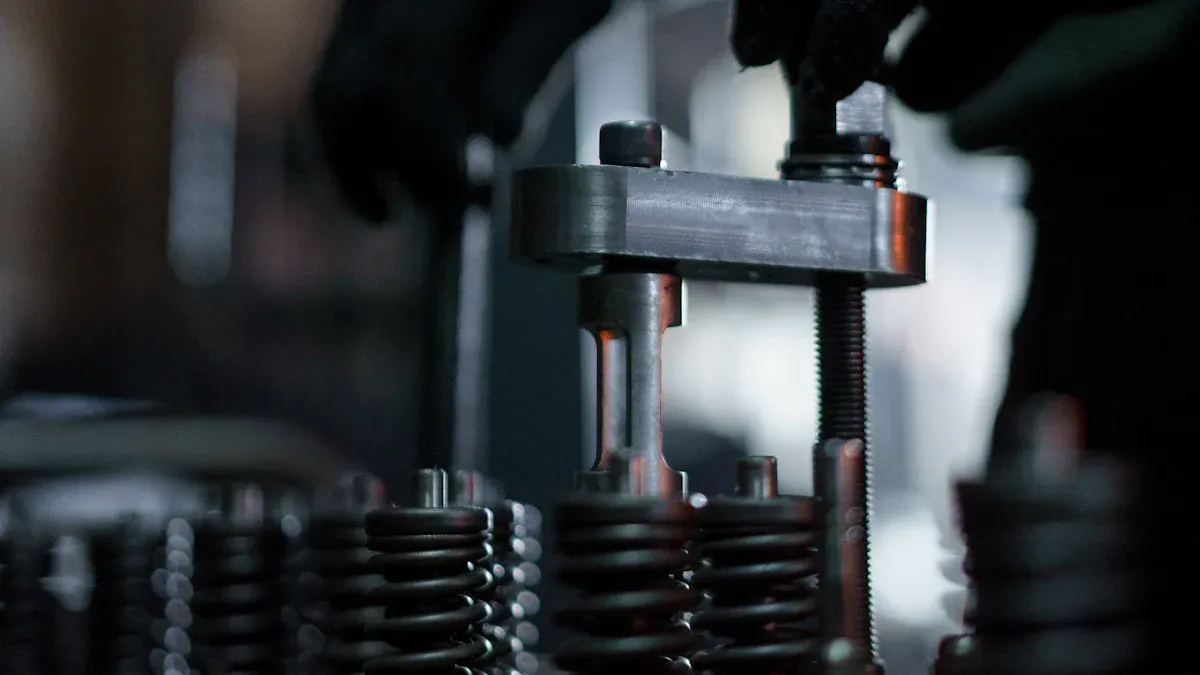

Inspection Methods for Injection Screw Barrels

Inspecting injection screw barrels regularly helps operators catch damage early and avoid costly repairs. Here are three effective methods to ensure barrels stay in top condition.

Visual Examination

Visual checks are the simplest way to spot damage. Operators can look for scratches, dents, or discoloration inside the barrel. These signs often indicate wear or corrosion. Using a flashlight makes it easier to see hard-to-reach areas.

Corrosion is especially common when barrels process materials like PVC or other corrosive plastics. Regular visual inspections can catch these issues before they worsen. Operators should also check for material build-up or leaks around the barrel. These problems can disrupt production and lead to further damage.

Tip: Schedule visual inspections weekly to stay ahead of potential issues.

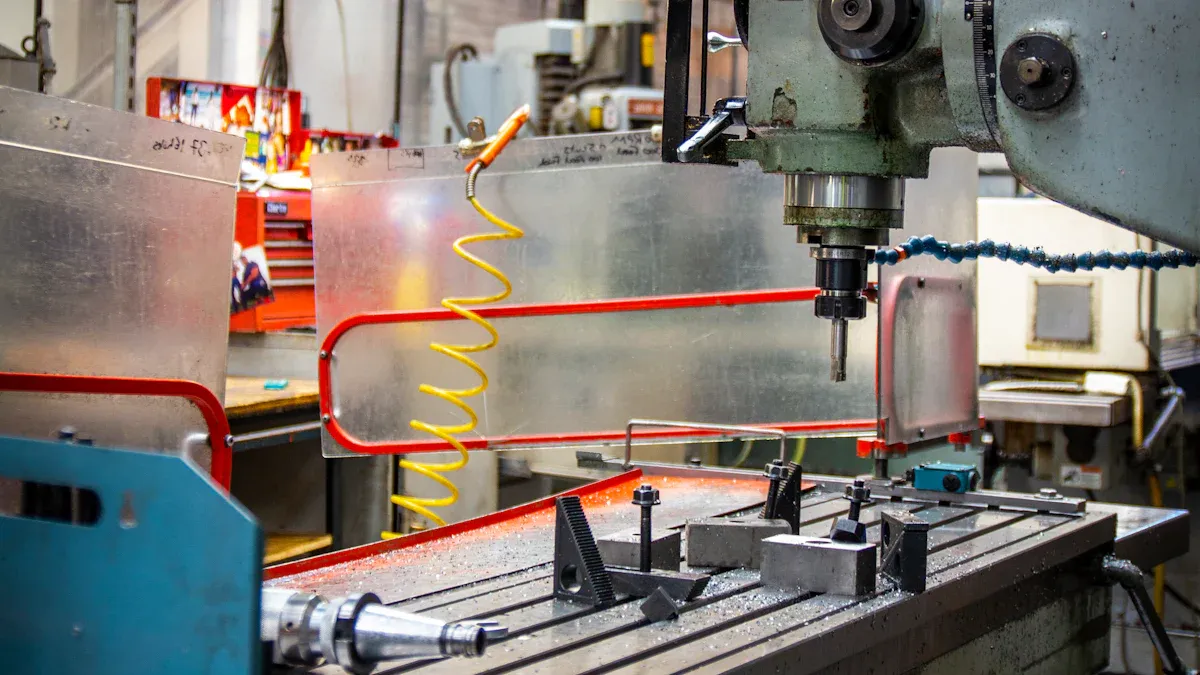

Using Measurement Tools

Measurement tools provide precise data on barrel wear. They help operators detect early signs of damage that might not be visible. One effective system is the Glycon EMT System, which uses Micro-Epsilon sensors to measure wear inside the barrel.

Here’s how these tools work:

| Measurement Tool | Description |

|---|---|

| Glycon EMT System | Utilizes Micro-Epsilon sensors for precise wear measurement in injection screw barrels. |

| Micro-Epsilon Sensors | Robust sensors that provide accurate readings at operating temperatures up to 600°F. |

| Measurement Process | Involves removing the barrel plug, installing the sensor, and measuring the distance between screw OD and barrel ID. |

| Data Transmission | Wear and production data are sent to an Electronic Measurement and Tracking portal for analysis. |

| Predictive Analytics | Allows for the calculation of wear rates and prediction of future wear, optimizing replacement schedules. |

These tools not only measure wear but also provide predictive analytics. Operators can use this data to plan maintenance and replacements, reducing downtime.

Note: Investing in measurement tools can save money in the long run by preventing unexpected failures.

Performance Testing

Performance tests reveal how well the barrel handles production. Operators can monitor benchmarks like temperature changes, shear rate, and slot width to detect damage. For example, a damaged barrel may struggle to maintain consistent temperatures, leading to uneven product quality.

Here’s a breakdown of key benchmarks:

| Performance Test Benchmark | Correlation with Damage Detection |

|---|---|

| Temperature Change | Positive correlation with offset degree; offset decreases with increasing temperature. |

| Shear Rate | Influences temperature; significant changes observed at higher speeds. |

| Depth Change | Positive correlation; offset decreases with increasing depth. |

| Slot Width | Increases shear temperature, affecting feed temperature and pressure. |

Monitoring these benchmarks helps operators identify when a barrel needs attention. For example, if the shear rate changes significantly, it could mean the barrel is wearing unevenly. Addressing these issues early ensures consistent production and minimizes waste.

Tip: Record performance data regularly to spot trends and prevent damage.

Preventing Damage to Injection Screw Barrels

Routine Maintenance Practices

Routine maintenance is the backbone of keeping an injection screw barrel in top condition. Operators who take ownership of maintenance tasks often ensure better care of the equipment. This proactive approach extends the lifespan of the machinery and prevents unexpected breakdowns.

Here are some essential maintenance practices:

- Inspect and clean screws and barrels regularly to avoid material build-up.

- Lubricate moving parts to minimize friction and wear.

- Maintain optimal processing temperatures to prevent overheating.

- Monitor for wear and ensure proper alignment during installation.

Tip: Create a preventive maintenance checklist and schedule regular downtime for inspections. Equipping operators with the right tools can also help address minor issues immediately.

Selecting Compatible Materials

Choosing the right materials for production is critical to preventing damage. Abrasive additives like calcium carbonate or glass fibers can wear down the barrel’s surface quickly. Corrosive materials, on the other hand, may react with the barrel, causing long-term degradation.

Evaluating raw materials for compatibility ensures durability and reduces the risk of damage. For example, bimetallic barrels are ideal for handling abrasive or corrosive materials due to their wear-resistant properties. Operators should always match the barrel’s specifications with the materials being processed.

Note: Using incompatible materials can lead to performance issues and shorten the lifespan of the barrel.

Optimizing Machine Settings

Incorrect machine settings can strain the injection screw barrel, leading to premature wear. Operators should optimize settings like temperature, pressure, and speed to match the material being processed. For instance, excessive pressure can cause unnecessary stress on the barrel, while low temperatures may result in uneven wear.

Regularly reviewing and adjusting these settings ensures smooth operation and consistent product quality. Operators should also monitor performance metrics to identify potential issues early.

Tip: Train operators to understand the impact of machine settings on barrel performance. This knowledge helps them make informed adjustments during production.

Identifying damage in injection screw barrels early keeps operations running smoothly and reduces costs. Regular inspections and maintenance go a long way in extending equipment life. Preventive measures, like using compatible materials and optimizing settings, ensure consistent product quality.

Remember: A proactive approach minimizes downtime and keeps production efficient.

FAQ

What is the best way to clean an injection screw barrel?

Use a soft brush and a non-abrasive cleaning agent. Avoid metal tools to prevent scratches. Regular cleaning keeps the barrel efficient and damage-free.

How often should operators inspect injection screw barrels?

Weekly inspections are ideal. Frequent checks help catch wear, leaks, or build-up early, ensuring smooth production and reducing costly downtime.

Tip: Create a simple inspection checklist to stay consistent.

Can bimetallic barrels handle abrasive materials better?

Yes! Bimetallic barrels resist wear and corrosion, making them perfect for abrasive or corrosive materials like filled plastics or engineering plastics.

Note: Always match the barrel type to the material for optimal performance.

Post time: Jun-10-2025