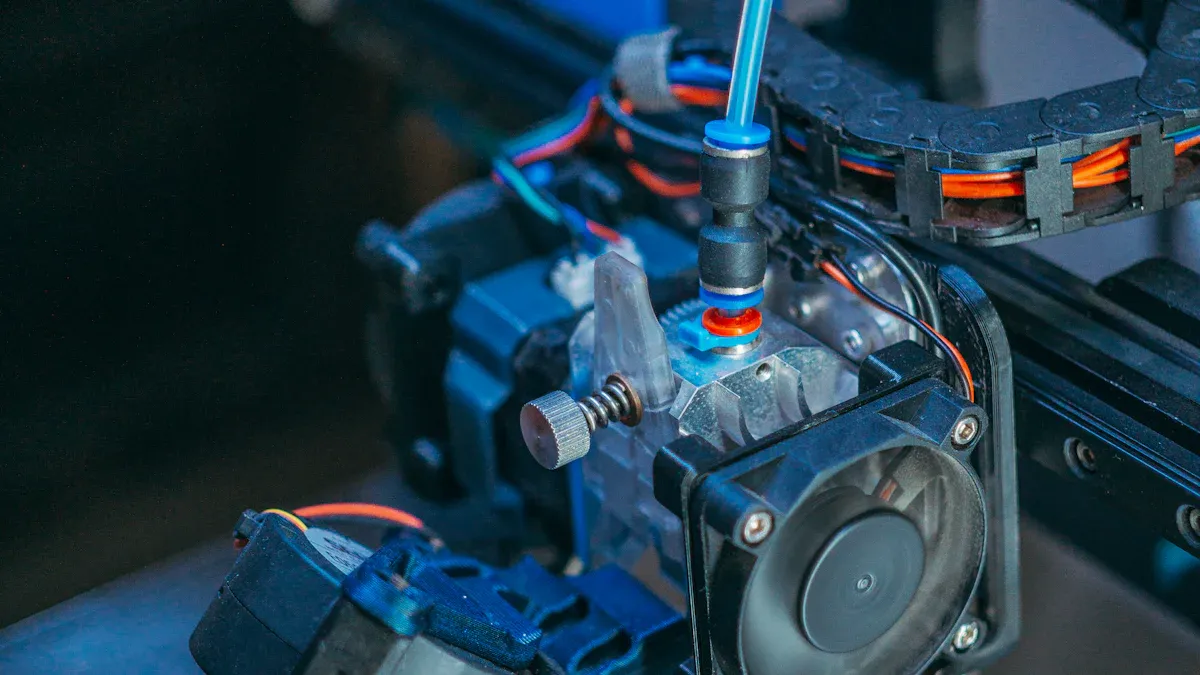

Choosing the right twin screw plastic extruders ensures efficiency and precision in injection molding processes. These machines enhance material mixing, improve capacity, and expand processing capabilities, making them indispensable for high-volume production.

- The global twin screw extruder market, valued at USD 1,128.1 million in 2022, is projected to reach USD 1,649.5 million by 2031.

- A 4.5% annual growth rate highlights their increasing demand across industries.

- Advanced designs, such as twin-screw extruder screw barrels, optimize performance and reliability.

Compatibility, customization, and cost-effectiveness remain critical factors when selecting a double screw extruder for specific applications, particularly when considering a double screw extruder machine tailored to meet unique production needs.

Importance of Twin Screw Plastic Extruders

Benefits for Injection Molding

Twin screw plastic extruders play a pivotal role in enhancing the efficiency and quality of injection molding processes. Their advanced design enables precise control over compounding, devolatilization, and mixing, which are essential for producing high-quality molded parts. By managing pressure effectively, these machines maintain optimal melt temperature and viscosity, ensuring consistent product performance.

Key benefits include:

- Transitioning industries from batch to continuous processing, significantly improving efficiency.

- Customizing material properties through superior mixing capabilities, which directly impacts product quality.

- Facilitating devolatilization with strategically placed vents, preventing flooding and ensuring the removal of volatiles.

- Allowing independent control of feed rates and screw RPMs, optimizing compounding and devolatilization processes.

The co-rotating, intermeshing design of twin screw plastic extruders is widely regarded as the most efficient compounding solution in the plastics industry. This makes them indispensable for manufacturers seeking to achieve precision and reliability in injection molding.

Advantages Over Single Screw Extruders

Twin screw plastic extruders offer several advantages over their single screw counterparts, particularly in terms of processing capabilities, flexibility, and efficiency. The following table highlights key differences:

| Feature | Single Screw Extruder | Twin Screw Extruder |

|---|---|---|

| Processing Capabilities | Basic extrusion and simple compounding. | Handles complex materials and intricate mixing. |

| Throughput and Efficiency | Lower throughput, suitable for small-scale production. | Higher throughput, ensuring better product quality. |

| Flexibility and Versatility | Limited flexibility, simpler operation. | Highly flexible with adjustable parameters. |

| Material Flexibility | Suitable for basic thermoplastics and fillers. | Ideal for complex formulations and high-viscosity materials. |

| Mixing Capability | Adequate for simple formulations. | Superior mixing, perfect for additive incorporation. |

| Degassing and Devolatilization | Limited capability. | Excellent capability, meeting stringent quality standards. |

These advantages make twin screw plastic extruders the preferred choice for manufacturers aiming to enhance production efficiency and product quality. Their ability to handle diverse materials and complex formulations ensures they remain a cornerstone of modern injection molding processes.

Key Factors to Consider When Choosing Twin Screw Plastic Extruders

Compatibility with Injection Molding Machines

Selecting a twin screw plastic extruder that aligns with the specifications of your injection molding machine is critical. Compatibility ensures seamless integration, reducing downtime and improving overall efficiency. Manufacturers must evaluate the extruder’s output capacity, screw design, and material handling capabilities to match the requirements of their molding machines. For instance, an extruder with a higher torque density and screw speed can handle complex materials, ensuring consistent feeding and melting processes.

A well-matched extruder also minimizes energy consumption and wear on components. The following table highlights how key factors like screw speed and material properties impact performance:

| Key Factor | Impact on Energy Consumption | Impact on Pressure | Impact on Torque |

|---|---|---|---|

| Screw Rotational Speed (n) | Significant reduction in specific energy consumption (45% decrease) with increased speed | Increased pressure by 3.1 MPa (65%) with higher speed | Increased torque with higher speed |

| Bran Content (u) | No significant impact on energy consumption | Increased pressure by 3.8 MPa (75%) with reduced bran content | Decreased torque by 34% with increased bran content |

Understanding these metrics helps manufacturers choose an extruder that complements their injection molding setup.

Customization Options for Specific Applications

Twin screw plastic extruders offer unparalleled customization options, making them ideal for diverse applications. These machines allow manufacturers to tailor screw designs to specific unit operations, such as mixing, devolatilization, or compounding. Each screw element serves a distinct purpose, and minor adjustments can significantly influence material processing outcomes.

Key customization features include:

- Flexible screw configurations to optimize mixing and material flow.

- Rearrangeable barrel sections to enhance the extrusion process without extensive modifications.

This level of adaptability ensures that manufacturers can meet unique production requirements while maintaining cost efficiency. For example, industries requiring high-viscosity materials or intricate formulations benefit from these customizable features.

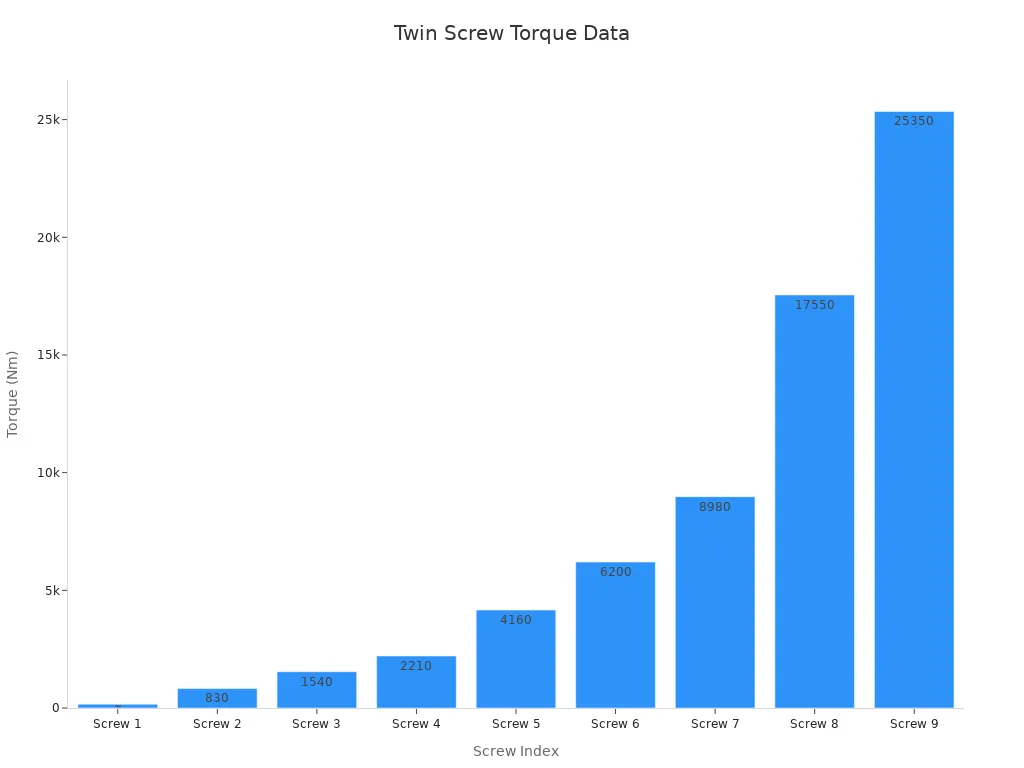

Performance Metrics: Torque, Speed, and Material Throughput

Performance metrics play a vital role in determining the efficiency of twin screw plastic extruders. Torque density, screw speed, and material throughput are critical parameters that influence the machine’s ability to process materials effectively. High torque density, for instance, allows the extruder to handle demanding applications, such as compounding reinforced polymers or processing high-viscosity materials.

The table below provides a snapshot of performance data for twin screw extruders:

| Parameter | Value |

|---|---|

| Torque Density | High strength up to 18 Nm/cm³ |

| Torque on Each Screw (Nm) | 160, 830, 1540, 2210, 4160, 6200, 8980, 17550, 25350 |

| Screw Speed (rpm) | 1200 for most models, some at 500 |

| Material Throughput | Capacity of 2,700 kg/h in PP+glass fiber application |

These metrics highlight the superior performance of twin screw extruders compared to industry standards, making them a reliable choice for high-volume production.

Cost and Budget Considerations

Cost is a significant factor when selecting a twin screw plastic extruder. Manufacturers must balance initial investment costs with long-term operational efficiency. While high-performance extruders may have a higher upfront cost, their energy efficiency, durability, and reduced maintenance requirements often result in lower total ownership costs.

Factors influencing cost include:

- Screw and barrel material quality.

- Customization requirements.

- Advanced features like automated controls and monitoring systems.

Investing in a high-quality extruder from a reputable manufacturer ensures better performance and availability of spare parts, reducing downtime and maintenance expenses.

Reliability and Maintenance Requirements

Reliability is essential for maintaining consistent production quality. Twin screw plastic extruders with high-quality components, such as screws, barrels, and gearboxes, offer better durability and performance. Regular maintenance is equally important to prevent mechanical failures and extend the machine’s lifespan.

Key maintenance practices include:

- Monitoring process parameters to identify potential issues early.

- Implementing preventive maintenance programs to reduce wear and tear.

- Training staff to recognize patterns in trend curves for effective troubleshooting.

Extruder screws and barrels experience wear over time, which can affect output rates and discharge temperatures. Manufacturers should consider the economic implications of replacing worn components to maintain profitability. Selecting a reliable extruder minimizes these challenges, ensuring long-term operational success.

Evaluating Manufacturers and Suppliers

Criteria for Selecting a Reputable Manufacturer

Choosing the right manufacturer for twin screw plastic extruders is critical to ensuring long-term success in injection molding operations. Reputable manufacturers demonstrate a commitment to innovation, quality, and customer satisfaction. Evaluating their strategies and market presence provides valuable insights into their reliability.

| Strategy Type | Description |

|---|---|

| Continuous Innovation | Companies invest in R&D to enhance performance and efficiency of extruders, meeting diverse industry needs. |

| Strategic Partnerships | Alliances with industry players and research institutions to leverage expertise and expand applications. |

| Mergers and Acquisitions | Enhancing production capabilities and market access through strategic mergers and acquisitions. |

Manufacturers that prioritize these strategies often deliver cutting-edge solutions tailored to industry demands. For instance, Zhejiang Jinteng Machinery Manufacturing Co., Ltd. exemplifies this approach by combining advanced design capabilities with precision machining equipment. Their focus on innovation and quality control ensures consistent performance and customer satisfaction.

Role of Customer Reviews and Testimonials

Customer reviews and testimonials provide valuable insights into a manufacturer’s reputation and product reliability. These firsthand accounts highlight real-world experiences, helping potential buyers make informed decisions. Positive reviews often emphasize key aspects such as product durability, ease of operation, and after-sales support.

Tip: Look for reviews that detail long-term performance and maintenance experiences. These insights often reveal the true value of the extruder beyond its initial purchase.

Testimonials from industry professionals can also validate a manufacturer’s claims. For example, feedback from companies using twin screw extruders for high-viscosity materials or complex formulations can confirm the machine’s capabilities. A consistent pattern of positive reviews indicates a manufacturer’s commitment to quality and customer satisfaction.

Importance of Warranties and Technical Support

Warranties and technical support play a vital role in ensuring uninterrupted production operations. A comprehensive warranty reflects the manufacturer’s confidence in their product’s durability and performance. Reliable technical support minimizes downtime and addresses operational challenges effectively.

Key benefits of robust post-purchase support include:

- Reliable maintenance ensures operational efficiency.

- Easy access to spare parts reduces production delays.

- Comprehensive technical support facilitates uninterrupted operations.

Manufacturers offering extensive warranties and responsive support services demonstrate a commitment to customer success. For instance, companies equipped with advanced monitoring and testing equipment can provide precise diagnostics and faster resolutions. This level of support not only enhances machine longevity but also builds trust with customers.

Note: Always verify the availability of spare parts and the responsiveness of technical support teams before finalizing a purchase. These factors significantly impact long-term operational efficiency.

Choosing the right twin screw plastic extruder involves evaluating compatibility, customization, performance, cost, and reliability. Manufacturers should prioritize reputable suppliers with strong warranties and technical support. Avoiding rushed decisions ensures long-term success.

Tip: Create a checklist of requirements and compare options systematically to make an informed purchase.

Post time: May-22-2025