Selecting high quality nitrided screws and barrels is crucial for ensuring optimal performance in machinery. Factors such as material type, design compatibility, and application requirements significantly influence this choice. Informed decisions not only enhance the operational lifespan of components like the Extrusion Machine Single Screw Barrel and the Pvc Pipe Single Screw Barrel but also improve overall efficiency and productivity.

Material Selection for Nitrided Screws and Barrels

Choosing the right materials for nitrided screws and barrels is essential for achieving optimal performance in various applications. The materials used significantly influence the durability, efficiency, and overall effectiveness of these components.

Types of Materials

Several materials are commonly used in the manufacturing of nitrided screws and barrels. Each material has unique characteristics that affect its suitability for specific applications. Here are some of the most prevalent materials:

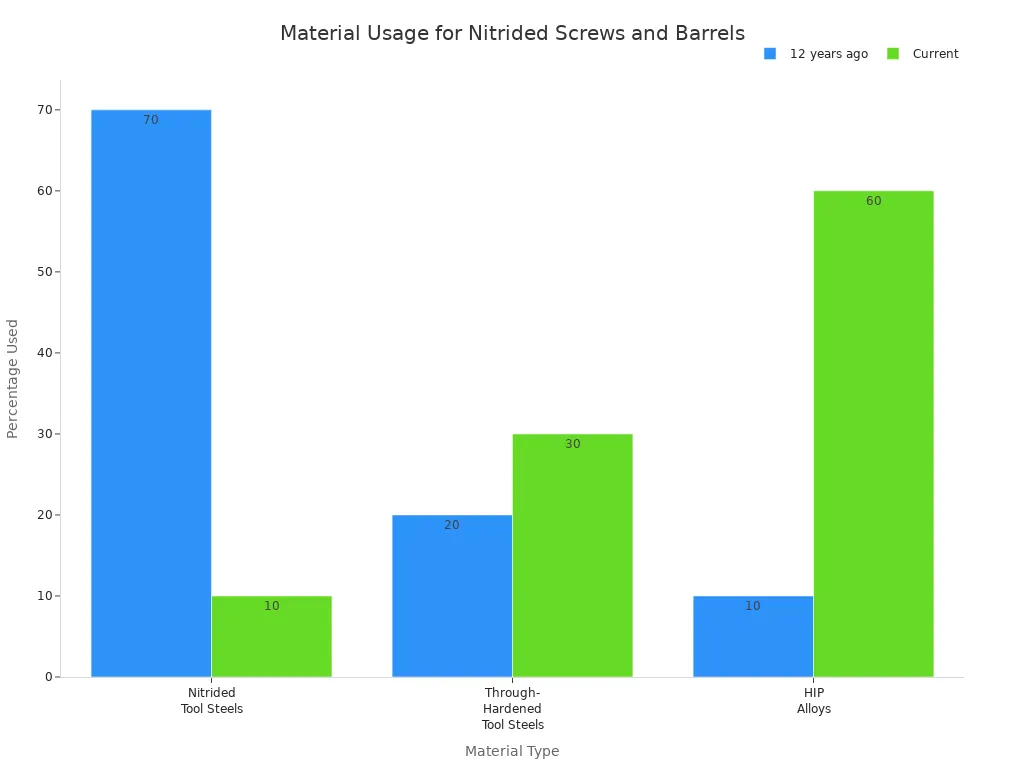

- Nitrided Tool Steels: Historically, these steels accounted for about 70% of the market share twelve years ago. However, their usage has decreased to around 10% currently.

- Through-Hardened Tool Steels: This type has seen an increase in popularity, rising from 20% to 30% over the same period.

- HIP Alloys: These alloys have gained significant traction, moving from 10% to 60% in current usage.

The following table summarizes the changes in material usage over the years:

| Material Type | Percentage (12 years ago) | Percentage (Current) |

|---|---|---|

| Nitrided Tool Steels | 70% | 10% |

| Through-Hardened Tool Steels | 20% | 30% |

| HIP Alloys | 10% | 60% |

Properties of Nitrided Materials

Nitrided materials exhibit several advantageous properties that enhance their performance in industrial applications. The nitriding process introduces nitrogen into the surface of the material, forming a hard nitride layer. This layer significantly improves various mechanical properties, making nitrided materials highly desirable.

- Wear Resistance: Nitrided materials demonstrate excellent wear resistance due to the hard surface layer formed during nitriding. This property is crucial for components subjected to abrasive conditions, such as in extrusion processes.

- Corrosion Resistance: The nitride layer also provides improved resistance to corrosion, which is vital when dealing with molten polymers and other corrosive elements.

- Hardness: After nitriding, materials can achieve hardness levels exceeding 65 HRC. This increased hardness contributes to the overall strength and durability of the screws and barrels.

- Comprehensive Properties: Nitrided steel and specific alloys like 38CrMoAl are known for their excellent overall properties, making them suitable for various applications.

The following table outlines the key mechanical properties of nitrided materials used in screws and barrels:

| Property | Description |

|---|---|

| Wear Resistance | Nitrided materials exhibit excellent wear resistance due to the nitriding process. |

| Corrosion Resistance | They have good corrosion resistance, although some grades may have limitations. |

| Hardness | Post-nitriding hardness can exceed 65 HRC, enhancing overall strength. |

| Comprehensive Properties | Nitrided steel and 38CrMoAl are noted for their excellent overall properties. |

| Nitriding Layer Depth | Typically, the nitriding layer reaches 0.4-0.6 mm. |

Factors to Consider in Choosing Nitrided Components

When selecting nitrided screws and barrels, two critical factors come into play: design compatibility and application requirements. Understanding these factors ensures that the chosen components perform optimally in their intended environments.

Design Compatibility

Design compatibility is essential for the successful integration of nitrided screws and barrels into existing machinery. Several design features must be considered to ensure this compatibility:

| Design Feature | Description |

|---|---|

| Material Selection | Nitrided steel is preferred for its hard surface and corrosion resistance. |

| Barrel Coating | Bimetallic barrels with wear-resistant coatings are necessary for high-performance applications. |

| Screw Geometry | Specially designed screw geometries enhance plastification and output. |

| L/D Ratio | The ratio of screw length to diameter affects melting and mixing processes. |

| Compression Ratio | Higher compression ratios improve mixing performance and pressure output. |

| Flight Depth Measurement | Controls material transportation volume and barrel flow performance. |

Nitrided steel provides durability and resistance to wear, making it a popular choice. Bimetallic barrels enhance performance in abrasive environments, while longer screws improve material processing efficiency. Increased compression ratios lead to better mixing and pressure output, which are vital for achieving optimal production rates.

HMG Extrusions emphasizes the importance of using highly wear-resistant nitriding steel for screws. This attention to detail helps maintain stringent tolerance specifications, ensuring compatibility with existing machinery.

Application Requirements

Application requirements play a significant role in determining the suitability of nitrided screws and barrels. Key considerations include:

- Design Considerations: The design must account for material characteristics such as viscosity, melting point, and flow rate.

- Uniform Melting and Blending: Proper design ensures that plastic materials are uniformly melted and blended, preventing overheating and burning.

- Surface Smoothness: Optimizing surface smoothness is crucial for balancing material mixing, shearing, and conveying. This directly impacts production efficiency and product quality.

Dimensional tolerances also affect performance. Wear on screws and barrels can significantly impact plasticizing efficiency, back pressure, shot volume, cycle times, and part consistency. Worn components can reduce processing efficiency by up to 25%, increase energy consumption, and lead to defects in molded parts. Exceeding clearance between the screw and barrel can result in resin leakage, poor melt quality, and inconsistent injection pressure.

Maintenance Tips for Longevity

Proper maintenance of nitrided screws and barrels is essential for maximizing their lifespan and ensuring optimal performance. Implementing a strong preventive maintenance (PM) program can significantly minimize wear and extend the life of these components.

Cleaning and Care

Regular cleaning and lubrication are vital for preventing premature wear. Here are some recommended practices:

- Use Commercial Purging Compounds (CPCs): These compounds enhance cleaning efficiency and help remove residues from the screw and barrel.

- Follow Manufacturer Recommendations: Adhere to the guidelines provided by screw and barrel manufacturers for regular maintenance.

To maintain the components effectively, consider the following maintenance frequency:

| Maintenance Frequency | Task Description |

|---|---|

| Weekly | Change the lubricating oil filter of the reducer and check for impurities. |

| Monthly | Check the coaxiality of the motor coupling and calibrate it. |

| Quarterly | Complete disassembly inspection of the screw, barrel, and mold. |

Inspection and Replacement

Routine inspections are crucial for detecting wear or damage in nitrided screws and barrels. Technicians should include the following techniques in their maintenance programs:

- Conduct routine inspections of plasticizing components.

- Measure wear during scheduled inspections to create a wear profile.

- Identify the expected lifespan of components for planned replacement and repair.

Regularly inspecting screws and barrels allows for early detection of potential issues, enabling prompt intervention. The following table outlines the typical lifespan of various components:

| Component Type | Lifespan (Years) | Notes |

|---|---|---|

| Standard screws | 1 – 1.5 | For general-purpose plastics (e.g., PP/PE) |

| Standard screws | 0.5 – 0.67 | For fillers (e.g., fiberglass) |

| Barrel lifespan | 1.5 – 2 times | Typically longer than screw lifespan; replace if over 3 years old. |

| Replacement Strategy | N/A | Replace screw and barrel as a set for economic benefits. |

By following these maintenance tips, operators can ensure the longevity and reliability of high quality nitrided screws and barrels.

Cost Considerations for High Quality Nitrided Screw and Barrel

When investing in high-quality nitrided screws and barrels, understanding the cost implications is essential. Companies must balance initial expenses with long-term benefits to make informed decisions.

Budgeting for Quality

Budgeting for nitrided components requires careful consideration of various factors. Companies should evaluate the following aspects:

- Type of plastic processed: Determine whether the application involves standard or reinforced plastics. This choice influences the material selection and associated costs.

- Additives used: Assess how additives impact wear and longevity. These factors can significantly affect overall expenses.

- Production scale: High-volume operations should prioritize stronger alloys. Investing in durable materials pays off in the long run.

- Budget considerations: Opting for bimetallic or coated options can lead to long-term savings. These choices often reduce maintenance and replacement costs.

The high initial costs of bimetallic components, such as nitrided screws and barrels, arise from intricate manufacturing processes and specialized materials. This complexity leads to increased production costs, which significantly influence the final price of these components. In sectors like automotive, the demand for nitriding steel feed screw barrels stems from their superior hardness and wear resistance. These properties justify the elevated material and manufacturing costs.

Long-term Value vs. Initial Cost

Investing in high-quality nitrided components can yield substantial long-term savings. These components often last 2 to 5 times longer than non-nitrided alternatives. This longevity reduces the frequency of replacements and maintenance, resulting in a lower total cost of ownership for machinery and systems utilizing nitrided components.

The following table illustrates how various factors impact the cost of ownership:

| Factor | Impact on Cost of Ownership |

|---|---|

| Wear Resistance | Fewer replacements, lower costs |

| Maintenance Frequency | Less downtime, reduced labor expense |

| Energy Efficiency | Lower utility bills |

| Predictive Monitoring | Early detection, minimized repairs |

By considering both initial costs and long-term value, companies can make strategic decisions that enhance operational efficiency and reduce overall expenses. Investing in high-quality nitrided screws and barrels not only improves performance but also contributes to a more sustainable financial outlook.

Choosing the right nitrided screws and barrels involves careful consideration of material compatibility and maintenance practices. Key factors include selecting wear-resistant materials like nitrided steel and conducting regular inspections. By making informed choices, operators can enhance performance and extend the lifespan of their machinery components.

Key Takeaways:

- Material compatibility affects wear and corrosion resistance.

- Regular maintenance minimizes downtime and enhances efficiency.

FAQ

What is the nitriding process?

Nitriding is a surface hardening treatment that diffuses nitrogen into the material, forming a hard nitride layer.

How does nitriding improve screw and barrel performance?

Nitriding enhances wear resistance, corrosion resistance, and reduces friction, leading to longer service life and improved efficiency.

What maintenance practices extend the life of nitrided components?

Regular cleaning, lubrication, and inspections help detect wear early, ensuring optimal performance and longevity of nitrided screws and barrels.

Post time: Sep-16-2025