PVC pipe production relies heavily on precision, and that’s where a PVC pipe single screw barrel comes in. This equipment ensures smooth material flow and consistent mixing, which are critical for high-quality results. For example, an 8-inch diameter two-stage extruder can process between 14 and 23 kg/(hr. rpm) while maintaining precise pressure at 9 MPa. Single screw barrels factories design these tools to handle such demanding tasks efficiently, making them essential for manufacturers. Additionally, vented single screw extruder manufacturers focus on enhancing the performance of these systems, ensuring optimal output and quality in the production of PVC pipes.

Understanding PVC Pipe Single Screw Barrel

What Is a PVC Pipe Single Screw Barrel?

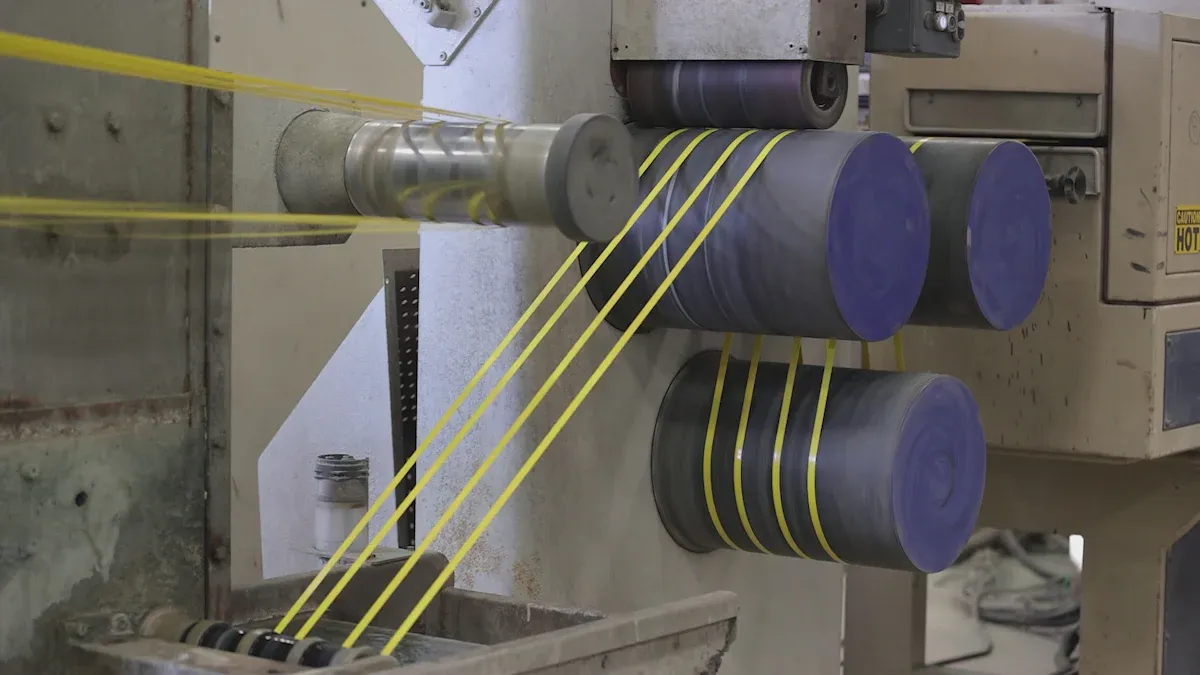

A PVC pipe single screw barrel is a critical component in the extrusion process used to manufacture PVC pipes. It consists of a cylindrical barrel and a rotating screw inside. This setup ensures that raw PVC material is melted, mixed, and pushed through a die to form pipes of specific shapes and sizes. The design of the screw and barrel plays a significant role in determining the quality of the final product.

Manufacturers often customize these barrels to meet specific production needs. For instance, the screw’s compression ratio and the barrel’s length-to-diameter (L/D) ratio are tailored to optimize material flow and mixing. This customization ensures that the PVC material is processed efficiently, resulting in pipes that are durable and uniform in quality.

How Does It Work in PVC Extrusion?

The single screw barrel operates as the heart of the extrusion process. It begins by feeding raw PVC material into the barrel. As the screw rotates, it generates heat through friction and external heaters, melting the material. The melted PVC is then mixed thoroughly to ensure uniformity before being pushed through a die to form the desired pipe shape.

The process involves several key parameters that influence the quality of the extrudate. These include the screw’s compression ratio, the barrel’s L/D ratio, and the processing conditions. The table below highlights how these parameters affect the properties of the extrudate:

| Parameter | Effect on Extrudate Properties |

|---|---|

| DDGS Levels | Significant decrease in die pressure with higher levels |

| Moisture Content | Significant differences in color and expansion ratio |

| Die Dimensions (L/D ratios) | Affects die pressure and expansion ratio |

| Screw Compression Ratios | Higher compression leads to significant changes |

| Processing Conditions | Influences extruder torque, die pressure, and mass flow rate |

By carefully controlling these factors, manufacturers can achieve precise mixing and consistent material flow, which are essential for producing high-quality PVC pipes.

Key Features That Enhance PVC Pipe Production

Several features of the PVC pipe single screw barrel make it indispensable in pipe production. First, its ability to maintain consistent material flow ensures that the pipes have uniform thickness and strength. Second, the screw’s design promotes thorough mixing, which eliminates defects like air bubbles or uneven textures in the final product.

Another standout feature is its adaptability. Manufacturers can adjust the screw’s design to suit different types of PVC materials, whether rigid or flexible. This flexibility allows for the production of a wide range of pipe types, from standard water pipes to specialized industrial pipes.

Statistical methods also play a role in optimizing the performance of single screw barrels. Techniques like factorial design of experiments and response surface analysis help manufacturers fine-tune the extrusion process. The table below illustrates how these methods contribute to optimization:

| Statistical Method | Application in Optimization |

|---|---|

| Factorial Design of Experiments | Locates extremum on response surfaces |

| Design of Experiments (DOE) | Develops strategies for screw optimization |

| Multiple Regression | Utilized with global extrusion models |

| Response Surface Analysis | Understands input-output variable relationships |

These features and optimization techniques ensure that the PVC pipe single screw barrel remains a reliable and efficient tool for manufacturers. Its ability to deliver consistent results makes it a cornerstone of the PVC pipe production process.

Benefits of PVC Pipe Single Screw Barrel in Manufacturing

Consistency in Material Flow and Mixing

Consistency is the backbone of quality in PVC pipe production. A PVC pipe single screw barrel ensures that raw materials flow smoothly through the extrusion process. The screw’s design plays a pivotal role here. Its carefully engineered grooves and compression zones melt and mix the PVC evenly. This uniformity prevents defects like air pockets or uneven textures in the final product.

Manufacturers benefit from this consistency in several ways. Pipes produced with uniform material distribution are stronger and more reliable. They meet industry standards more easily, reducing the need for costly rework. Additionally, the steady flow minimizes wear and tear on machinery, extending the lifespan of production equipment.

By maintaining consistent material flow and mixing, the single screw barrel not only enhances product quality but also streamlines the entire manufacturing process. This makes it an indispensable tool for PVC pipe production.

Improved Product Quality and Durability

The quality of PVC pipes depends heavily on how well the material is processed. A PVC pipe single screw barrel ensures that the PVC is melted and mixed to perfection. This precision eliminates common issues like weak spots or uneven wall thickness in the pipes. As a result, the pipes are more durable and can withstand higher pressures and harsher conditions.

Durability is especially important for pipes used in critical applications, such as water supply or industrial systems. Pipes made with single screw barrels are less likely to crack or fail over time. This reliability translates to fewer maintenance costs and longer service life for end-users.

Moreover, the adaptability of single screw barrels allows manufacturers to produce a wide range of pipe types. Whether it’s rigid pipes for construction or flexible ones for specialized uses, the single screw barrel ensures that each product meets the required specifications. This versatility adds significant value to the manufacturing process.

Energy Efficiency and Cost Savings

Energy efficiency is a major advantage of using single screw barrels in PVC pipe production. The optimized design of the screw reduces energy consumption by ensuring that the material melts and mixes efficiently. This not only lowers electricity costs but also reduces the environmental impact of the manufacturing process.

Cost savings go beyond energy efficiency. The streamlined operation of single screw barrels minimizes material waste, further cutting down expenses. For example:

- Optimized screw designs can save manufacturers approximately $168,000 annually.

- With a gross margin of 10%, the total value to the converter can reach $373,000 per year.

- If operational time increases to 300 days annually, the conversion cost can drop to $0.51/kg, reducing overall production costs to $2.13/kg. This results in an additional value of $255,000 annually.

These savings make single screw barrels a cost-effective choice for manufacturers. Additionally, the increased production rates—ranging from 18% to 43%—boost overall efficiency. This means manufacturers can produce more pipes in less time, further enhancing profitability.

By combining energy efficiency with significant cost savings, the single screw barrel proves to be a smart investment for PVC pipe manufacturers. Its ability to deliver high-quality results while keeping costs low makes it a cornerstone of modern extrusion technology.

Comparing Single Screw Barrels to Other Extrusion Methods

Single Screw vs. Twin Screw Extrusion

Single screw and twin screw extruders each have their strengths. Single screw extruders excel in energy efficiency. Their simpler design uses less power, making them ideal for straightforward extrusion tasks. On the other hand, twin screw extruders shine when it comes to mixing and handling complex materials. This makes them better suited for applications requiring intricate material blending.

For PVC pipe production, single screw extruders often take the lead. They provide consistent material flow and are easier to operate. Twin screw extruders, while powerful, can be more expensive to maintain and operate. Manufacturers often choose single screw extruders for their reliability and cost-effectiveness in producing high-quality PVC pipes.

Why Single Screw Barrels Are Ideal for PVC Pipe Production

Single screw barrels are a perfect match for PVC pipe production. Their design ensures smooth material flow and precise mixing. This consistency leads to pipes with uniform thickness and strength. The adaptability of single screw barrels also allows manufacturers to handle different types of PVC materials, whether rigid or flexible.

Another advantage is their energy efficiency. By using less power, single screw barrels reduce production costs and environmental impact. Their straightforward operation also minimizes downtime, helping manufacturers meet tight production schedules. These features make single screw barrels a reliable choice for producing durable and high-quality PVC pipes.

Challenges of Alternative Extrusion Methods

Alternative extrusion methods, like twin screw extrusion, come with their own set of challenges. Twin screw extruders, while excellent for complex mixing, require more energy and maintenance. Their intricate design can lead to higher operational costs. Additionally, they may not be as efficient for simpler tasks like standard PVC pipe production.

Other methods, such as ram extrusion, lack the precision and adaptability of single screw barrels. They often struggle with maintaining consistent material flow, which can result in defects in the final product. These limitations highlight why single screw barrels remain the preferred choice for PVC pipe manufacturing.

PVC pipe single screw barrels play a vital role in producing high-quality and durable pipes. Their design ensures consistent melt quality and precise control, which boosts efficiency. Manufacturers can rely on these barrels to meet industry standards while reducing costs. By adopting this technology, they can streamline production and deliver reliable products.

FAQ

What makes single screw barrels energy-efficient?

Single screw barrels optimize material melting and mixing, reducing energy consumption. Their streamlined design minimizes waste and ensures efficient heat transfer during PVC pipe production. ♻️

Can single screw barrels handle different PVC materials?

Yes! Manufacturers can customize screw designs to process rigid or flexible PVC, making them versatile for producing various pipe types.

How do single screw barrels improve pipe durability?

They ensure uniform material mixing and flow, eliminating weak spots. This results in pipes that withstand high pressure and harsh conditions, offering long-lasting performance.

Post time: May-27-2025