I see how Single Screw Barrels transform plastic recycling. When I use a Single screw barrel for recycling granulation, I notice better melt quality, steady mixing, and less wear. My Plastic Extruder For Plastic Recycling runs smoother. With precise temperature and screw speed, my Extruder For Plastic Recycling achieves higher output and pellet quality.

- Melting flux

- Screw speed

- Barrel temperature

- Shear stress management

Key Mechanisms Driving Efficiency

Improved Melt Homogenization

When I operate my recycling extruder, I focus on achieving a uniform melt. Melt homogenization means mixing the plastic thoroughly as it melts, so every pellet has the same quality. I have learned that controlling melt temperature and flow is essential. Studies on plastics like nylon and polypropylene show that when I keep the melt uniform, I get better recycled pellets. If the melt is not consistent, the recycled plastic can become weak or brittle.

I see the difference in pellet quality when I use a single screw barrel designed for better mixing. For example, research on melt-state shear homogenization shows that high-shear mixing in single screw barrels improves the physical and thermal uniformity of recycled plastics. This process reduces contaminants and changes the polymer structure in a way that helps with further recycling steps. I notice that my recycled pellets have fewer defects and better performance when the melt is homogeneous.

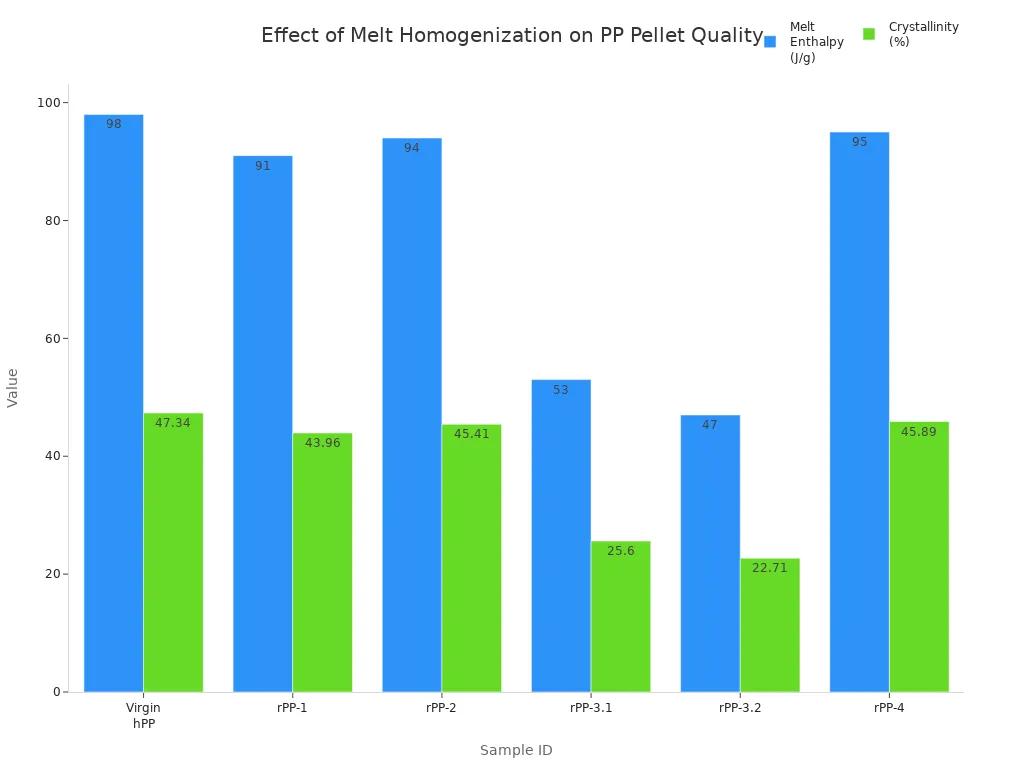

The numbers back up what I see in my shop. When I compare recycled polypropylene samples, those with higher crystallinity and melt enthalpy look and perform more like virgin plastic. Here is a table that shows how different processing conditions affect pellet quality:

| Sample ID | Melt Enthalpy (J/g) | Crystallinity (%) |

|---|---|---|

| Virgin homopolymer PP (hPP) | 98 | 47.34 |

| Recycled PP-1 (rPP-1) | 91 | 43.96 |

| Recycled PP-2 (rPP-2) | 94 | 45.41 |

| Recycled PP-3.1 (rPP-3.1) | 53 | 25.60 |

| Recycled PP-3.2 (rPP-3.2) | 47 | 22.71 |

| Recycled PP-4 (rPP-4) | 95 | 45.89 |

I always aim for results like rPP-1, rPP-2, and rPP-4, which are close to virgin PP. Lower values, like rPP-3.1 and rPP-3.2, tell me the melt was not mixed well or had contamination.

When I control melt flow and mixing, I also see better mechanical properties in the final product. My recycled pellets stretch and hold up almost as well as new plastic, which means I can use them in more demanding applications.

Optimized Screw Geometry

The shape and design of the screw inside my extruder make a big difference. I have tried different screw geometries and noticed how they affect energy use, melt quality, and output. When I use a screw with the right geometry, I get more consistent mixing and higher throughput. I also use less energy, which saves money and reduces wear on my equipment.

- Screw geometry affects how much energy I need and how steady the melt temperature stays.

- Increasing screw speed can lower energy use, but the screw design must match the material.

- Barrier screws and mixing elements help keep the melt temperature even and improve mixing.

- Some screw designs let me run the extruder faster without losing quality.

- The right screw geometry balances energy efficiency with high output and good melt quality.

I have seen that barrier screws, which separate solid and melted plastic, allow me to run at higher speeds and get more output. However, I need to watch the throughput to keep the melt uniform. Mixing elements like the Maddock shear section give me better homogenization, which means fewer defects in my pellets.

Here is a quick comparison of screw types and their effects:

| Screw Geometry | Mixing Consistency (Homogeneity) | Throughput | Notes |

|---|---|---|---|

| Barrier Screws | Good at high throughput, need careful control | High | Best for large batches, watch for uneven mixing at very high speeds |

| Three-Section Screws | Stable, but lower throughput | Moderate | Good for steady production, less flexible |

| Mixing Elements | Excellent homogenization | Varies | Maddock shear gives best mixing, especially for tough plastics |

I always choose the screw geometry that matches the plastic I am recycling. This way, I get the best balance of speed, quality, and energy use.

Advanced Barrel Materials

The material of the screw barrel matters just as much as its design. I rely on barrels made from high-quality alloy steels like 38CrMoAl, which offer strength and toughness. When I use barrels with nitrided surfaces, I see a big jump in hardness. This means my equipment lasts longer, even when I process abrasive or contaminated plastics.

- Alloy steels such as 38CrMoAlA and AISI 4140 give me the durability I need.

- Powder metallurgy steels provide even better wear and corrosion resistance.

- Nitriding treatments boost surface hardness, often reaching HV900 or more.

- Bimetallic coatings, like tungsten carbide, protect against abrasive fillers.

- Chromium plating adds another layer of defense against rust and wear.

I have noticed that when I use barrels with these advanced materials and coatings, I spend less time and money on maintenance. My extruder runs longer between service intervals, and I do not have to worry as much about breakdowns. This reliability lets me focus on producing high-quality recycled pellets.

Tip: Always match the barrel material to the types of plastics and additives you process. Tougher materials and coatings pay off when you handle abrasive or mixed plastic waste.

By combining improved melt homogenization, optimized screw geometry, and advanced barrel materials, I achieve higher efficiency and better results in my plastic recycling operation. These mechanisms work together to deliver consistent quality, higher output, and lower costs.

Solving Common Recycling Challenges

Tackling Contamination and Variable Feedstock

When I run my recycling operation, I face unpredictable feedstock every day. Some batches contain clean, uniform plastic. Others arrive mixed with dirt, metal, or moisture. I know that irregularly shaped regrind particles have lower bulk density than virgin pellets. This reduces throughput and makes my extruder work harder. If I do not address these issues, I see higher melt temperatures and degraded pellet quality.

I rely on my single screw barrel to handle these challenges. The optimized feed zone geometry, especially enlarged feed pockets, improves feeding and solids conveying. This design prevents material stagnation and keeps the flow steady. I notice that my extruder maintains melt quality even when I process mixed or contaminated plastics.

Here are the main challenges I encounter in plastic recycling:

- Irregular regrind shapes and low bulk density

- Reduced throughput and efficiency

- Higher melt temperatures and narrow processing windows

- Contamination and material degradation

- Processing variability with mixed plastics

My single screw barrel helps me overcome these problems. I see better feeding efficiency, consistent material flow, and lower energy consumption. This technology allows me to process a wider range of recycled plastics without sacrificing quality.

I often compare single screw extruders to twin screw extruders. Twin screw machines offer excellent mixing and degassing, but they struggle with high pressures and contamination. Single screw extruders, like mine, handle filtration-intensive recycling and tolerate contaminants better. Here is a quick comparison:

| Feature | Single Screw Extruder | Twin Screw Extruder |

|---|---|---|

| Mixing Efficiency | Moderate mixing, limited homogenization | Excellent mixing, intensive distributive/dispersive action |

| Temperature Uniformity | Moderate, prone to hot/cold spots | Highly uniform melt temperature distribution |

| Output Stability | Good, can have pulsation | Consistent, stable output |

| Material Versatility | Best for homogeneous, virgin materials | Handles additives, blends, contaminated feedstocks |

| Degassing Capability | Limited or none | High, with vacuum ports and venting zones |

| Ideal Use Case | Small scale, pure virgin ABS | Industrial scale, specialty, colored, recycled ABS |

I choose single screw barrels for their high-pressure capabilities and better tolerance of contaminants. This decision helps me avoid costly repairs and keeps my recycling line running smoothly.

Reducing Wear from Abrasive Materials

Abrasive plastics and fillers, such as glass fibers, talc, and calcium carbonate, present a major challenge in my plant. These materials wear down screws and barrels quickly. I used to replace components often, which increased downtime and costs.

Now, I use single screw barrels with advanced surface treatments and coatings. My barrel features a nitrided surface and bimetallic alloy layers. These enhancements boost hardness and resist abrasion. I see a big difference in durability. My equipment lasts longer, even when I process tough, abrasive plastics.

Key design features that help me minimize wear include:

- Optimized screw geometry to prevent pressure spikes and melt turbulence

- Selection of wear-resistant materials and specialized coatings

- Tailored design for specific raw materials and fillers

- Precise machining for smooth surface finish

- Simulation software to understand melt pressure distribution

I learned that the highest wear occurs near the transition section, where solids wedge and pressure rises. By choosing the right materials and coatings, I reduce wear by up to 60%. Regular inspection and maintenance of high-wear zones, such as the feeding and discharge areas, keep my extruder in top shape.

Tip: I always match my screw barrel design to the plastics and fillers I process. This approach extends equipment life and improves production efficiency.

Enhancing Process Stability and Output Consistency

Stable processing is essential for producing high-quality recycled pellets. Before I adopted single screw barrel technology, I struggled with flow surging, melting instabilities, and poor solids conveying. These problems led to lower production rates, increased scrap, and higher labor costs.

With my JT single screw barrel, I achieve stable melt flow and consistent output. Advanced control systems, including sensors and logic controllers, help me maintain steady temperature and pressure. I monitor process conditions closely to prevent fluctuations that could destabilize the operation.

I use bimetallic alloys and advanced coatings to enhance wear and corrosion resistance. These features are critical for processing abrasive or recycled plastics. Stable process conditions prevent variations in product properties and reduce waste.

Here are the steps I take to maintain process stability:

- Regular maintenance and timely replacement of worn screws and barrels

- Monitoring temperature and pressure with advanced control systems

- Using custom screw profiles for better melt homogeneity and mixing

- Inspecting high-wear zones to reduce unexpected downtime

Studies show that optimizing screw speed and temperature zones increases throughput and improves recyclability. Lower screw speeds increase torque and reduce mechanical energy, leading to better efficiency and more consistent output. I have documented output rate increases of 18% to 36% after optimizing my screw barrel design.

Note: Consistent inspection and predictive maintenance prolong equipment life and improve overall process stability in my recycling operation.

By addressing contamination, wear, and process stability, my single screw barrel helps me deliver reliable, high-quality recycled pellets. I meet the demands of modern recycling with confidence and efficiency.

Single Screw Barrel for Recycling Granulation: Real-World Results

Increased Throughput and Quality

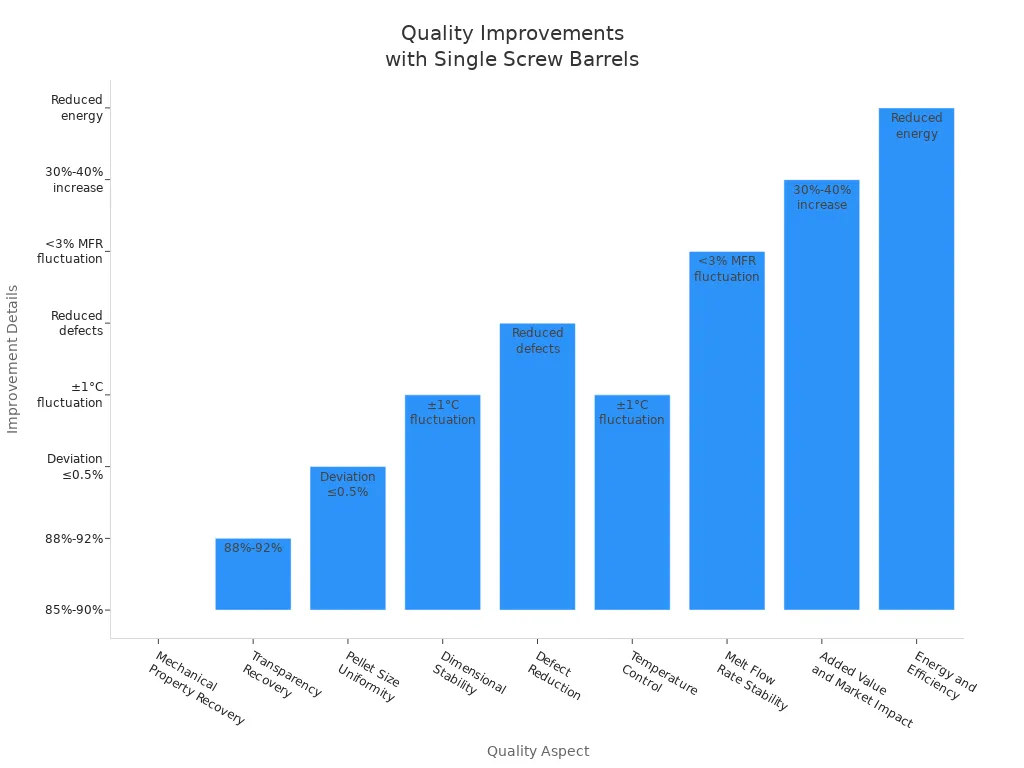

When I switched to a single screw barrel for recycling granulation, I saw a clear boost in both throughput and pellet quality. My recycled pellets now show better mechanical strength and improved transparency. I can control pellet size more precisely, which helps me meet strict customer requirements. The advanced temperature control keeps the melt flow steady, so I get fewer defects and more uniform pellets.

| Quality Aspect | Improvement Details |

|---|---|

| Mechanical Property Recovery | 85%-90% recovery rate, much higher than with ordinary equipment |

| Transparency Recovery | 88%-92% recovery rate |

| Pellet Size Uniformity | Size deviation within 0.5% |

| Dimensional Stability | Uniform temperature (±1°C fluctuation) ensures stability |

| Defect Reduction | Fewer impurities and defects |

| Temperature Control | Five-stage control, ±1°C fluctuation |

| Melt Flow Rate Stability | MFR fluctuation less than 3% |

| Added Value and Market Impact | 30%-40% increase in added value |

| Energy and Efficiency | Lower energy use, higher efficiency |

Lower Maintenance and Downtime

I have learned that regular care keeps my single screw barrel for recycling granulation running smoothly. I follow a strict maintenance schedule and inspect the barrel every week. I always keep the temperature and screw speed steady to avoid stress on the machine. Clean, sorted plastic feedstock helps prevent damage from contaminants. I clean and lubricate moving parts to stop rust and friction. When I see worn parts, I replace them right away. I choose barrels made from tough alloys with special coatings, like nitriding, to extend their life.

- Weekly barrel inspections keep my equipment in top shape.

- Correct temperature and pressure settings prevent wear.

- Clean feedstock reduces internal damage.

- Regular cleaning and lubrication stop breakdowns.

- Proactive part replacement avoids unexpected downtime.

- Tough alloys and coatings make the barrel last longer.

Plants that follow these steps report less downtime and lower repair costs. My recycling line now runs more efficiently and reliably.

Case Study: JT Single Screw Barrel in Multi-Plastic Recycling

I installed the JT single screw barrel for recycling granulation in my plant to handle different plastics like PE, PP, and PVC. The wear-resistant materials, such as 38CrMoAl and tungsten carbide, have extended the barrel’s life. I now spend less on repairs and replacements. My production line rarely stops, so I meet my delivery deadlines. The consistent performance of the JT single screw barrel for recycling granulation has improved my output and reduced my costs. I see fewer interruptions and better pellet quality, which helps me stay competitive in the market.

I see how single screw barrels solve key recycling problems. My experience shows better melt quality, mixing, and process stability. With the single screw barrel for recycling granulation, I achieve higher efficiency and reliability. These improvements support cleaner operations, lower costs, and help me meet growing industry demands for sustainable plastic recycling.

FAQ

What plastics can I process with the JT single screw barrel?

I can process many plastics, including PE, PP, PS, PVC, PET, PC, and PA. The barrel adapts to different materials for efficient recycling.

How do I reduce wear on my screw barrel?

I use barrels made from tough alloys with nitrided or bimetallic coatings. Regular cleaning and proper settings help me extend the barrel’s life and keep performance high.

Why does melt homogenization matter in recycling?

Melt homogenization gives me uniform pellets. I see fewer defects and better product strength. Consistent mixing helps me meet quality standards and customer needs.

Post time: Aug-21-2025