A plastic injection molding screw barrel plays a big role in shaping melt quality and production speed. Engineers focus on the Injection Molding Barrel design to boost performance. They use different materials for Single Screw Plastic Extruder Machine and Single Screw Extrusion Machine. Each choice helps machines process plastics better.

Plastic Injection Molding Screw Barrel Structure and Performance

Barrel Types: Bimetallic vs. Integral

Choosing the right barrel type can make a big difference in how a Plastic Injection molding screw barrel performs. Bimetallic barrels use a strong steel base with a tough alloy lining inside. This design saves valuable materials and lets manufacturers replace only the worn lining, which makes maintenance easier and more cost-effective. The fit between the lining and the barrel must be precise to keep heat flowing smoothly and prevent movement. Bimetallic barrels work well for processing abrasive or reinforced plastics because they resist wear and last longer.

Integral barrels are made as a single piece. This gives them high precision and even heat distribution along the barrel. They make it easier to install and maintain heating and cooling systems. However, they need strict manufacturing controls to keep quality high. When comparing the two, integral barrels offer simple maintenance and uniform heating, while bimetallic barrels provide better wear resistance and easier part replacement.

| Performance Aspect | Integral Barrel | Bimetallic Barrel |

|---|---|---|

| Construction | Single-piece, high manufacturing precision | Base barrel with replaceable alloy steel bushing |

| Heat Distribution | Uniform heat distribution along barrel axis | Heat conduction maintained if bushing fit is precise |

| Wear Resistance | Standard wear resistance | Enhanced wear resistance due to alloy steel lining |

| Maintenance | Easier installation and maintenance of heating/cooling systems | Replaceable bushing allows easier part replacement |

| Material Usage | Requires higher precision and material quality | Conserves valuable materials by using alloy steel only in lining |

Bimetallic barrels often last much longer than integral barrels, especially when processing tough materials. Their design reduces downtime and replacement costs, which helps keep production running smoothly.

Screw Geometry: L/D Ratio, Compression Ratio, and Flight Design

The geometry of the screw inside a Plastic Injection molding screw barrel shapes how plastics melt and mix. The L/D ratio, which compares the screw’s length to its diameter, affects melt uniformity and mixing. A longer screw (higher L/D ratio) gives plastic more time to melt and mix, which improves product quality. However, if the screw is too long, it can cause thermal degradation, especially with heat-sensitive plastics. Materials like PVC and POM need shorter screws to avoid damage, while glass-filled or high-viscosity plastics benefit from longer screws and reinforced mixing zones.

- Materials with good thermal stability use longer screws for better mixing.

- Heat-sensitive plastics need shorter screws or special thread designs.

- General purpose screws (L/D ~20:1) suit common plastics but may show color variation.

- Barrier screws (L/D ~24:1) improve mixing for reinforced plastics.

- Separation screws (L/D ~18:1) help heat-sensitive materials avoid degradation.

- Mixing screws (L/D ~22:1) provide uniform melt for specialty plastics.

The compression ratio measures how much the screw compresses the plastic. High-viscosity plastics need a higher compression ratio to melt and mix well. Adjusting the compression ratio helps balance throughput and product quality. Manufacturers often monitor and optimize screw design to match the material’s needs.

Screw flight design also matters. Rheologically optimized screws improve melt quality by matching the flow behavior of the polymer. Controlled Melt Delivery systems help control melt temperature and viscosity, reducing the risk of degradation. Mixing screws and dynamic barrier screws provide uniform melt and prevent dead spots, which keeps the plastic from overheating or discoloring.

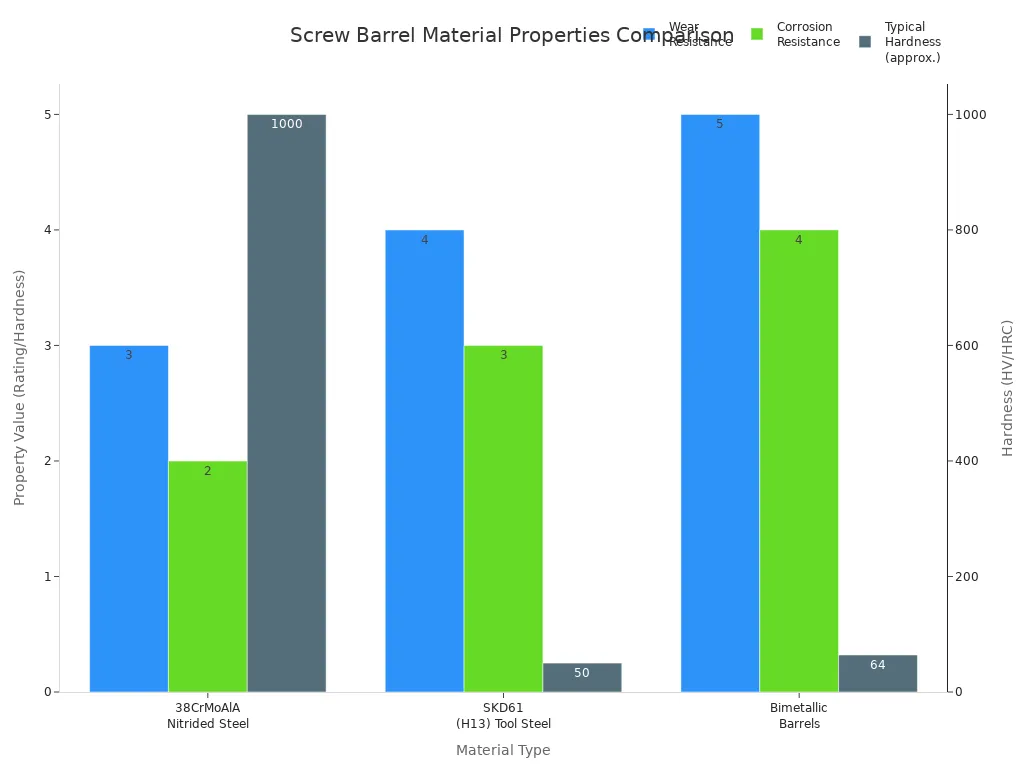

Material Composition and Surface Treatments

The materials used to make a Plastic Injection molding screw barrel affect its durability and performance. Nitrided steel offers good hardness and wear resistance for standard plastics. Bimetallic barrels combine a steel base with an alloy liner, giving excellent wear and corrosion resistance for tough or filled plastics. Tool steel provides high strength and wear resistance for extreme environments.

| Material Type | Key Properties & Pros | Cons & Limitations | Best Applications |

|---|---|---|---|

| Nitrided Steel | High surface hardness; good wear resistance for unfilled resins; affordable | Poor corrosion resistance; unsuitable for abrasive/chemical resins | Commodity resins like polyethylene, polypropylene |

| Bimetallic Barrels | Steel backing with alloy liner; excellent wear and corrosion resistance; longer lifespan | More expensive; may be overkill for general use | Glass-filled nylons, flame-retardant ABS, PVC, aggressive polymers |

| Nickel-Based Alloys | Exceptional corrosion resistance; good for flame-retardant and halogenated resins | Less hard than iron-based alloys; lower wear resistance | Chemically aggressive polymers |

| Iron-Based Alloys | Superior hardness and wear resistance | Lower corrosion resistance than nickel-based alloys | Abrasive, highly filled resins |

| Tool Steel | Exceptional hardness and strength; high wear resistance | High cost; susceptible to corrosion without coatings | Extreme wear environments, high-output applications |

| Specialty Coated Barrels | Coatings like tungsten carbide or chrome plating improve wear and corrosion resistance | Adds cost and complexity; coating adhesion varies | Custom or aggressive resin applications |

Surface treatments like nitriding and chrome plating boost wear resistance and lifespan. Nitriding can double or triple the service life of screws and barrels. Chrome plating increases hardness and corrosion resistance, but nitriding often performs better under abrasive conditions. Molybdenum spraying combined with nitriding gives even more protection. Proper operation and maintenance help maximize these benefits.

Feeding Port and Venting Design

The feeding port design controls how plastic enters the barrel. Good temperature control at the feeding port keeps material viscosity steady, which helps maintain consistent flow and feeding. Vacuum loaders and hopper receivers make sure material moves smoothly into the machine, reducing contamination and spillage. This setup keeps production quality high and feeding consistent.

- Vacuum loaders mount directly on the machine throat, reducing contamination.

- Hopper receivers use gravity to feed material, simplifying the process.

Venting design also plays a key role. Vent screws have special zones that remove moisture and volatiles during processing. This is important for hygroscopic materials and recycled plastics. Venting ports let gases and moisture escape, preventing defects and keeping extrusion quality high.

Tip: Proper feeding port and venting design help maintain steady production and improve product quality, especially when working with recycled or sensitive plastics.

Performance Outcomes of Plastic Injection Molding Screw Barrel Design

Melt Quality and Homogeneity

A well-designed Plastic Injection molding screw barrel helps create a smooth and even melt. The screw’s geometry, including its compression ratio and the shape of its zones, controls how plastic pellets melt and mix. When the compression ratio matches the material, the melt flows evenly. This reduces problems like splay marks or incomplete melting. The feed zone moves and warms the pellets, the compression zone melts and presses the material, and the metering zone makes sure the melt is even. Features like channel depth and mixing sections help the screw heat and blend the plastic. Barrier screws can separate solid and melted plastic, making melting more efficient and saving energy.

When the melt is uniform, the final product looks better and works better. Poor mixing can cause color streaks, weak spots, or changes in part size. Good melt homogeneity means fewer defects and more reliable parts. Operators can also use sensors to watch melt quality and adjust settings for better results.

- Poor melt mixing causes color streaks and weak spots.

- Good melt quality leads to consistent part size and strength.

- Melt quality depends on barrel temperature, screw speed, and backpressure.

Note: Keeping the melt temperature steady and matching screw design to the plastic type helps avoid defects and keeps product quality high.

Mixing Efficiency and Cycle Time

Mixing efficiency depends on the screw’s shape and special features. As the screw turns, it pushes and folds the plastic, creating strong shear forces. Mixing sections near the tip, like pins or barrier flights, help blend the melt. This action spreads color and additives evenly, so the final part looks smooth and uniform. Barrier screws use a second flight to separate melted plastic from solid bits, speeding up melting and preventing unmelted chunks.

- Screw geometry controls how pellets move, melt, and blend.

- Mixing sections create a looping motion, blending over 95% of the material quickly.

- Barrier screws and special designs help disperse color and additives.

Mixing efficiency also affects cycle time. Faster and more even melting means the machine can run more cycles in less time. Using barrier screws, larger diameter screws, or deeper grooves increases plasticizing speed. Raising screw speed (when safe for the material) and reducing back pressure can also shorten cycle times. Advanced heating and cooling systems keep the barrel at the right temperature, helping parts cool faster and keeping production moving.

- Optimized screw barrel design prevents clogs and delays.

- Precise heating and cooling systems help parts solidify quickly.

- Durable materials and coatings reduce downtime for repairs.

Wear Resistance and Maintenance

Wear is a big concern for any Plastic Injection molding screw barrel. Abrasive fillers, corrosive plastics, and long production runs can wear down the screw and barrel. Common wear types include adhesive wear, abrasive wear, and corrosion. For example, abrasive wear happens when hard fillers like glass fiber rub against the metal. Corrosive wear comes from chemicals in plastics like PVC.

| Wear Mechanism | Description | Design Mitigation Strategies |

|---|---|---|

| Adhesive Wear | Metal surfaces contact and transfer material. | Use hardfacing alloys, check for scoring, ensure material compatibility. |

| Abrasive Wear | Shearing action from pellets or fillers. | Use hard alloys, avoid abrasive fillers, keep feedstock clean. |

| Corrosive Wear | Chemical attack from certain plastics. | Use corrosion-resistant materials, avoid harsh chemicals. |

| Alignment Issues | Misalignment causes rubbing and uneven wear. | Ensure straightness and proper alignment. |

Material choice and surface treatments make a big difference. Liquid nitriding increases surface hardness and wear resistance. Bimetallic barrels with special liners last longer, especially with tough plastics. Regular inspections and preventive maintenance, like cleaning and checking alignment, help catch problems early. Advanced coatings and new materials can extend barrel life by up to 40%, lowering maintenance costs and reducing downtime.

- Maintenance frequency depends on barrel material and coatings.

- Preventive maintenance and regular inspections extend barrel life.

- Advanced surface treatments reduce repairs and replacements.

Adaptability to Different Materials and Applications

A flexible screw barrel design lets manufacturers process many types of plastics. Screw geometry, such as length, pitch, and channel depth, can be changed to suit different materials. General-purpose, barrier, and mixing screws each work best with certain plastics. Cooling systems, like water channels, keep the barrel at the right temperature for each material.

- Screw design and geometry match different plastics.

- Cooling systems prevent overheating.

- High-strength alloys and coatings handle tough conditions.

Adaptable designs also make it easier to switch between jobs. Features like quick-disconnect adapters and screw pushers help operators change screws fast. Adaptive process controls use sensors and machine learning to adjust settings in real time. This reduces manual changes and speeds up changeovers, so production can switch from one material or product to another with less downtime.

Tip: Adaptable screw barrel designs help factories handle many types of plastics and switch jobs quickly, keeping production flexible and efficient.

Troubleshooting Common Performance Issues

Even with the best design, problems can happen. Common issues include excessive wear, temperature problems, blockages, noise, and color mixing errors. Each problem has its own causes and solutions.

| Performance Issue | Description and Symptoms | Causes and Solutions |

|---|---|---|

| Excessive Wear | Material leaks, poor quality, high temperatures, noise | Use bimetallic barrels, hardfacing alloys, regular cleaning, proper alignment |

| Temperature Regulation | Discoloration, charring, bubbles, warping | Divide barrel into zones, use sensors, gradual preheating, insulation jackets |

| Blockage and Build-Up | High pressure, poor flow, black specks | Clean with purge compounds, proper screw speed, seal barrel during downtime |

| Noise or Vibration | Loud noises, vibration, friction | Inspect alignment, bearings, use vibration damping, isolate components |

| Color Mixing/Contamination | Color streaks, inconsistent shades, contamination | Use purging compounds, regular cleaning, optimize screw design, seal machines during shutdowns |

Operators can solve many problems by following a few key steps:

- Optimize screw configuration and barrel temperature zones.

- Monitor and adjust temperatures and screw speed.

- Calibrate feeders and prevent material bridging.

- Inspect screws and barrels for wear, especially in high-stress areas.

- Use predictive maintenance to plan repairs and reduce downtime.

- Keep a spare screw and refurbish only a few times.

- Train operators to spot early warning signs.

Note: Regular cleaning, proper lubrication, and careful monitoring help keep the Plastic Injection molding screw barrel running smoothly and extend its life.

Optimizing the structure of a Plastic Injection molding screw barrel boosts melt quality and equipment life. When manufacturers select the right barrel type, screw geometry, and materials, they see smoother flow, better mixing, and fewer defects. Regular maintenance, including cleaning and inspections, keeps machines running efficiently and lowers costs.

FAQ

What is the main benefit of a bimetallic screw barrel?

Bimetallic barrels resist wear from tough plastics. They last longer and reduce downtime for maintenance.

How often should operators inspect the screw barrel?

Operators should check the screw barrel every month. Regular inspections help catch wear early and keep machines running smoothly.

Can one screw barrel work with many types of plastics?

| Barrel Type | Adaptability |

|---|---|

| General Purpose | Good |

| Barrier | Excellent |

| Mixing | Very Good |

A well-designed barrel can handle many plastics, but some materials need special features.

Post time: Aug-25-2025