Bottle Blow molding screw barrel design stands apart from injection molding due to its longer length and higher compression ratio. This helps create uniform parisons, which improves bottle clarity and strength. As the global blow molded plastics market grows, the Blowing Screw Barrel and Film Blown Screw deliver efficient melting, mixing, and energy savings over the Single Plastic Screw Barrel.

Screw Barrel Function in Molding Processes

Material Melting and Conveying Roles

The screw barrel acts as the heart of both bottle blow molding and injection molding machines. Its main job is to melt plastic pellets and move the molten material forward. In injection molding, the screw rotates inside the heated barrel, compressing and melting the plastic. Once the plastic melts, the screw pushes it into a mold at high pressure. This process shapes the plastic into solid parts.

In bottle blow molding, the screw barrel also melts the polymer. However, the way it moves the material can change. For example, in extrusion blow molding, the screw can turn continuously or in steps. It pushes the melted plastic out as a tube, called a parison. Air then blows into the parison to form a bottle. In injection blow molding, the screw injects the melted plastic into a mold to make a preform, which later becomes a bottle. The screw barrel adapts its role based on the molding process, but always focuses on melting and moving the plastic efficiently.

Tip: A well-designed screw barrel ensures the plastic melts evenly and flows smoothly, which helps prevent defects in the final product.

Mixing and Homogeneity Effects

Mixing and homogeneity play a huge role in product quality. The screw barrel must blend the plastic and any additives so the final part looks and performs as expected. Different screw designs can change how well the plastic mixes. For example, screws with special channels or mixing sections help distribute colorants and additives more evenly. This leads to better color and fewer weak spots.

Manufacturers often test how well a screw mixes by checking the temperature and color of the melted plastic. They look for even temperatures and smooth color blends. A lower standard deviation in these tests means better mixing. Some advanced screws, like barrier or multichannel designs, show improved mixing and more uniform melts. These features help create bottles and parts that are strong, clear, and free from streaks or bubbles.

| Measurement Aspect | Method Description | What It Shows |

|---|---|---|

| Thermal Homogeneity | Check melt temperature at screw tip | Even heating |

| Material Homogeneity | Analyze color blend in melt samples | Even mixing |

| Screw Performance Index | Combines both thermal and material homogeneity | Overall melt quality |

A screw barrel that mixes well gives manufacturers more control over product quality and reduces waste.

Key Differences in Screw Barrel Design

Geometry and Dimensions

Screw barrel geometry shapes how plastic moves and melts inside the machine. In bottle blow molding, the screw barrel often has a longer length-to-diameter (L/D) ratio compared to injection molding. This extra length gives the plastic more time to melt and mix, which is important for making strong, clear bottles. The Bottle Blow molding screw barrel usually features a gradual taper and deeper feed channels. These design choices help the screw handle a steady flow of plastic and create a uniform parison.

Injection molding screw barrels, on the other hand, tend to be shorter. They focus on quickly melting and injecting plastic into a mold. The shorter length helps speed up the cycle time and fits the fast-paced nature of injection molding. The geometry of each screw barrel matches the needs of its process, balancing melting, mixing, and pressure.

Note: The right geometry can improve melt quality and reduce energy use by controlling how much shear and heat the plastic experiences.

Compression Ratio and Functional Zones

The compression ratio is a key part of screw barrel design. It measures how much the screw compresses the plastic as it moves from the feed zone to the metering zone. In bottle blow molding, the Bottle Blow molding screw barrel often uses a higher compression ratio. This helps build up the pressure needed to form a smooth, bubble-free parison. The higher ratio also improves mixing and melt homogeneity, which leads to better bottle clarity and strength.

Injection molding screw barrels may use a lower or moderate compression ratio, depending on the material. For example, a low compression ratio can cause defects like splay in polystyrene, while a higher ratio improves compaction and reduces cycle time. However, if the ratio is too high for certain materials like ABS, it can cause process instability and incomplete melting. The design of the functional zones—feed, transition, and metering—also plays a big role. Adjusting the depth and length of these zones changes how the plastic melts and flows, affecting pressure and screw performance.

- Compression ratio must match the polymer type and process needs.

- Proper design of functional zones ensures stable melting and prevents defects.

- Fine-tuning these features can improve melt quality and boost plant capacity.

Material Handling and Plasticizing Needs

Different molding processes have unique plasticizing needs. The Bottle Blow molding screw barrel must handle a wide range of materials, from high-density polyethylene (HDPE) to polypropylene (PP). It needs to melt and mix these materials evenly to create a parison with consistent thickness. This is important because uneven melting can lead to weak spots or cloudy bottles.

Injection molding screw barrels focus on quickly melting the plastic and injecting it into a mold. They often work with materials that need precise temperature control and fast plasticizing. Some materials, like high-viscosity resins, can be challenging to process in injection blow molding. The screw barrel design must account for these differences to ensure smooth operation.

| Aspect | Extrusion Blow Molding (EBM) | Injection Blow Molding (IBM) |

|---|---|---|

| Scrap | 5% to 30% scrap, needs recycling, adds variability. | Minimal scrap with proper tooling; only from start-up or color changes. |

| Plastic Orientation | Parison blown at high temp, little orientation. | Some orientation during injection, improves properties. |

| Tooling Cost | Lower, good for small runs. | Higher, but efficient for large runs. |

| Clarity | Possible die lines or defects. | Clear containers due to better control. |

| Bottom Pinch-off Scar | Present, can affect appearance. | None, better appearance and strength. |

| Bottom Push-off | Harder due to pinch-off. | Easier with retractable plugs. |

Tip: Matching the screw barrel design to the material and process helps reduce scrap, improve clarity, and make stronger bottles.

Wear Resistance and Material Compatibility

Wear resistance is a big concern for both bottle blow molding and injection molding. The screw and barrel face constant friction and pressure from the moving plastic. Fillers and additives in the plastic can make wear even worse. The Bottle Blow molding screw barrel often uses high-quality nitrided steel, bimetallic alloys, or special coatings like tungsten carbide to fight wear and corrosion. These materials help the screw last longer, even when processing abrasive or corrosive polymers.

Injection molding barrels may use materials like Nitralloy nitride, D2 tool steel, CPM 10V, or even carbide for tough jobs. Each material offers different levels of protection against wear and corrosion. For example, CPM 10V works well with glass-filled or flame-retardant plastics, while carbide barrels are best for very abrasive materials. Matching the screw and barrel materials is important to avoid problems with thermal expansion and binding.

- Common wear issues include wedging, abrasive wear, and misalignment wear.

- Using the right materials and coatings extends the life of the screw barrel.

- Regular checks for wear patterns can help spot problems early and guide design improvements.

Remember: A well-chosen screw barrel material keeps the machine running smoothly and reduces downtime for repairs.

Bottle Blow Molding Screw Barrel Features

Design Adaptations for Parison Quality

Manufacturers design the Bottle Blow molding screw barrel with several features to improve parison quality. These adaptations help create bottles with even walls and smooth surfaces. Here are some of the most important design choices:

- The screw barrel provides precise control over how the plastic melts and flows. This control helps keep the parison’s wall thickness uniform, which leads to better-looking bottles.

- Engineers use high-grade materials like nitrided steel, bimetallic alloys, and tungsten carbide coatings. These materials make the screw barrel more durable and resistant to wear, so it keeps working well over time.

- Customization is common. Manufacturers can change the screw’s diameter, length-to-diameter ratio (L/D), flight shape, and surface coatings. These options let them match the screw barrel to different plastics and production needs.

- These design features help optimize important processing factors. For example, they can shorten cycle times, improve cooling, and make bottle sizes more accurate.

A well-designed Bottle Blow molding screw barrel gives companies more control over the final product, making it easier to produce bottles that look good and perform well.

Temperature Control and Homogeneity

Temperature control plays a huge role in blow molding. The screw barrel must keep the plastic at just the right temperature to ensure it melts evenly and flows smoothly. If the temperature is too high or too low, the plastic might not form a good parison.

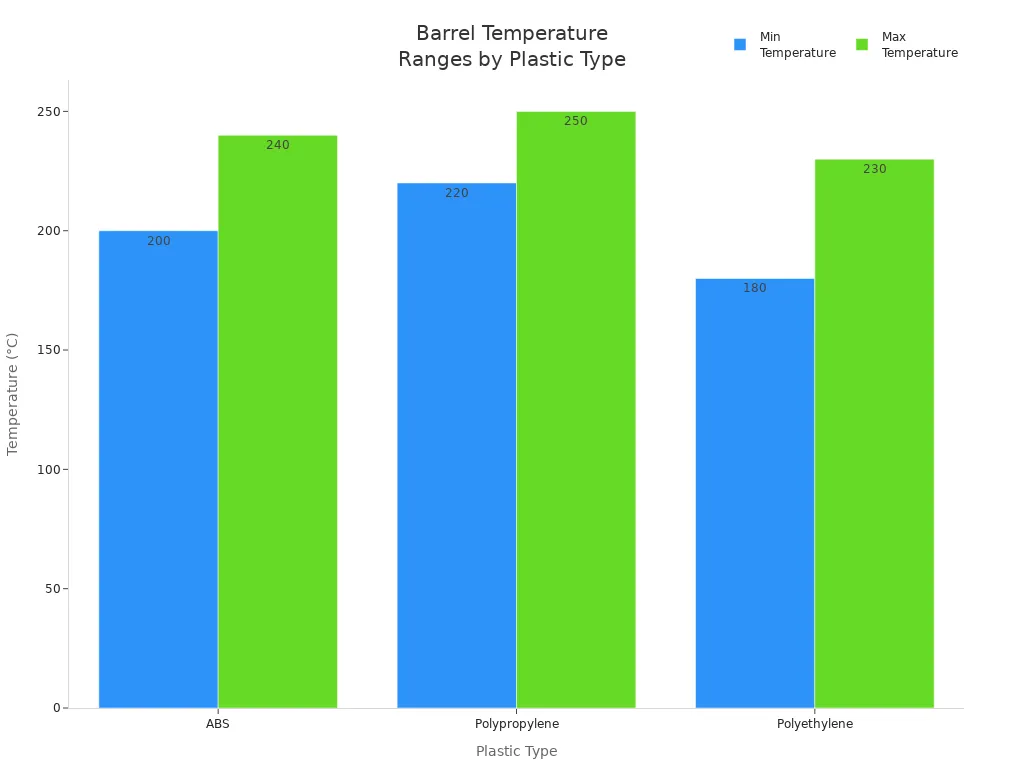

| Plastic Type | Typical Barrel Temperature Range (°C) |

|---|---|

| ABS | 200 – 240 |

| Polypropylene | 220 – 250 |

| Polyethylene | 180 – 230 |

Operators use heater bands and sensors to manage these temperatures. The screw design also affects how well the plastic heats up and mixes. Hot spots can appear in the transition zone of the screw, causing the temperature to spike. To fix this, manufacturers might adjust the screw speed, add cooling fans, or insulate heater bands. These steps help keep the melt temperature steady, which is key for making bottles with consistent quality.

A good Bottle Blow molding screw barrel design also improves homogeneity. Features like grooved feed screws and deep flights help the plastic melt and mix better. Barrier mixing sections near the end of the screw blend the polymer evenly. This uniform melt leads to stable parison formation and fewer defects.

When the temperature stays steady and the melt is uniform, the process runs smoother and the bottles come out stronger and clearer.

Impact on Bottle Clarity and Strength

The design of the screw barrel has a direct effect on how clear and strong the finished bottles are. A longer screw with a high length-to-diameter ratio (often between 24:1 and 30:1) gives the plastic more time to melt and mix. A higher compression ratio, usually around 3.5:1, helps create a smooth, bubble-free melt. These features work together to improve the flow of plastic and the quality of the parison.

Advancements in screw barrel technology have made it easier to produce lightweight bottles without losing strength. Improved material flow reduces blockages and keeps production running. Optimized heat transfer helps maintain the best processing temperatures, which leads to better melt quality and more consistent bottles. Durable materials like heat-treated alloy steel mean fewer repairs and less downtime.

Manufacturers can also customize the screw barrel to fit different production needs. Some use integrated sensors to monitor melt pressure and temperature in real time. This allows for quick adjustments and helps prevent problems before they affect the product.

- Grooved feed screws and deep flights improve resin melting and mixing, which is important for making clear bottles.

- Barrier mixing sections ensure the polymer blends evenly, reducing streaks and weak spots.

- High compression ratios allow for thinner, lighter bottle walls while keeping them strong.

With these design improvements, companies can make bottles that are not only lighter but also clearer and tougher, meeting the demands of today’s packaging industry.

Comparison Table: Bottle Blow Molding vs. Injection Molding Screw Barrels

Side-by-Side Feature Summary

When comparing bottle blow molding and injection molding screw barrels, several differences stand out. The table below highlights the most important features side by side:

| Feature | Bottle Blow Molding Screw Barrel | Injection Molding Screw Barrel |

|---|---|---|

| Plastic Melting Method | Melts and extrudes plastic to form a hollow parison | Melts and injects plastic into a preform mold |

| Product Dimensionality | Makes 2D hollow products like bottles and containers | Produces 3D hollow parts with high precision |

| Materials Used | HDPE, PP, PET | Acrylic, Polycarbonate, POM, PE |

| Mold Design & Precision | Flexible design, lower precision | High precision, accurate resin flow |

| Scrap Generation | Generates flash that needs trimming | Scrap-free, no trimming required |

| Tooling Costs | Lower, flexible tooling | Higher, less flexible |

| Production Speed | Slower, operator skill important | Faster, ideal for high volume |

| Product Types | Larger containers, complex shapes, handles | Small, precise parts with tight tolerances |

| Weight & Material Control | Less precise, harder to calibrate wall thickness | Precise weight and uniform material distribution |

| Container Size Range | Less than 1 oz. up to 55 gallons | Best for 5 oz. or less, not economical over 16 oz. |

| Mold Requirements | Single mold type | Needs injection and blow molds |

Tip: Regular maintenance keeps both types of screw barrels running smoothly. For bottle blow molding, operators clean the screw and barrel often to prevent residue buildup. They also monitor temperature and lubricate moving parts. In injection molding, teams inspect the screw and barrel each year, check process variables, and maintain hydraulic oil and heater bands. These steps help ensure consistent product quality and extend equipment life.

Manufacturers see clear differences in screw barrel design for bottle blow molding and injection molding. The Bottle Blow molding screw barrel uses longer geometry and precise temperature control to boost parison quality. Key factors like screw shape, material selection, and real-time monitoring help improve efficiency and product consistency.

- Screw geometry shapes melting and mixing, reducing waste and improving quality.

- Careful material selection prevents wear and overheating, especially with abrasive plastics.

| Challenge | Impact on Manufacturing |

|---|---|

| Material selection | Prevents wear and extends lifespan |

| Temperature control | Maintains product clarity and strength |

| Operational practices | Reduces downtime and defects |

Choosing the right screw barrel design leads to better bottles, less waste, and smoother production.

FAQ

What makes a blow molding screw barrel different from an injection molding screw barrel?

A blow molding screw barrel is longer and uses a higher compression ratio. This design helps create uniform parisons for strong, clear bottles.

How does screw barrel design affect bottle quality?

The screw barrel controls melting and mixing. Good design leads to even wall thickness, better clarity, and stronger bottles.

Can manufacturers use the same screw barrel for both processes?

No, each process needs a specific screw barrel. Using the right design ensures smooth operation and high-quality products.

Post time: Jul-25-2025