Selecting a parallel twin screw barrel tailored to extrusion needs ensures peak performance in manufacturing. Leading brands in 2025, such as Coperion and KraussMaffei, drive innovation to meet evolving demands.

- The smart manufacturing market, including advanced die technologies, is growing at 11.7% CAGR.

- Sustainable materials now address 85% of lifecycle emissions.

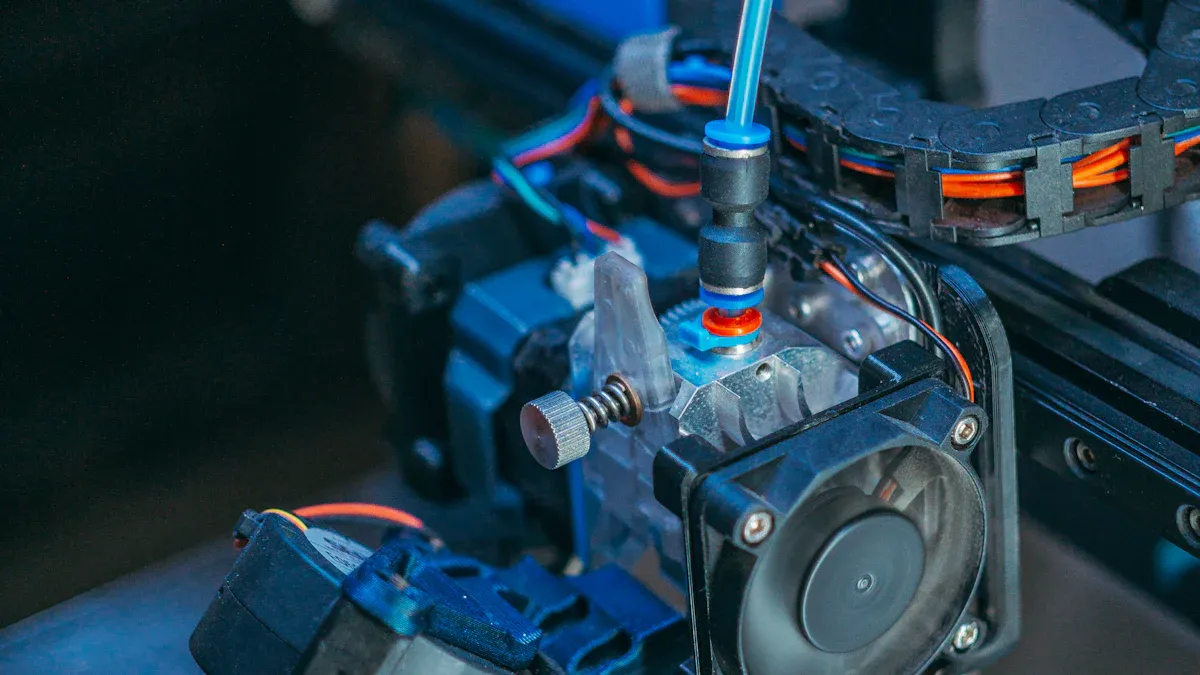

Conical and parallel twin screw barrels, essential for efficient processing, align with these advancements. Their precision reduces waste and enhances cost efficiency, making them a cornerstone of good twin screw and plastic barrels.

Top Manufacturers and Suppliers of Parallel Twin Screw Barrels

The global extrusion industry relies on innovative manufacturers to deliver high-quality parallel twin screw barrels. These companies lead the market with advanced technology, precision engineering, and a commitment to customer satisfaction. Below is an overview of the top manufacturers and their contributions to the industry.

Coperion

Coperion has established itself as a pioneer in the extrusion industry. The company specializes in closely intermeshing, co-rotating twin-screw extruders, which are integral to the performance of parallel twin screw barrels.

- Over 15,000 compounding systems installed worldwide highlight Coperion’s extensive market presence.

- Since the 1950s, the company has consistently set new standards in machine and system design for processing technology.

- Its innovative solutions ensure efficient material processing, making it a trusted name in the industry.

Coperion’s expertise in developing high-performance systems ensures reliable and consistent results for various applications, including plastics and food processing.

Leistritz

Leistritz is renowned for its advanced extrusion technology. The company focuses on co-rotating screws and precise temperature control, which enhance the performance of parallel twin screw barrels.

| Brand | Technical Parameters | Pros | Cons |

|---|---|---|---|

| Leistritz | Co-rotating screws, Temperature control | Enhanced mixing, High production capacity | Higher initial investment costs |

Leistritz’s commitment to innovation ensures high production capacity and superior mixing capabilities. Its systems are ideal for industries requiring precise material processing.

KraussMaffei

KraussMaffei combines versatility and precision in its extrusion systems. The company offers both co-rotating and counter-rotating designs, catering to a wide range of applications.

| Brand | Technical Parameters | Pros | Cons |

|---|---|---|---|

| KraussMaffei | Co-rotating and counter-rotating designs | High mixing capabilities, Wide applications | Requires skilled operation and maintenance |

KraussMaffei’s systems excel in mixing and material handling, making them a preferred choice for industries such as plastics and chemicals.

Zhejiang Zhongyang Screw Manufacturing Co., Ltd.

Zhejiang Zhongyang Screw Manufacturing Co., Ltd. is a leading supplier of parallel twin screw barrels in Asia. The company focuses on delivering durable and high-quality products tailored to customer needs.

- Its barrels are engineered for uniform melting, mixing, and conveying of materials.

- The company serves diverse industries, including plastics, rubber, and food processing.

- Customization options ensure compatibility with various extrusion systems.

Zhejiang Zhongyang’s commitment to quality and innovation has earned it a strong reputation in the global market.

Shanghai Jurry Plastic Machinery Co., Ltd.

Shanghai Jurry Plastic Machinery Co., Ltd. specializes in manufacturing parallel twin screw barrels for PVC pipe production. The company designs its products to ensure efficient and uniform processing of PVC compounds.

- Specialized screw elements and barrel geometry enhance material handling.

- The company’s products deliver consistent results, ensuring high-quality PVC pipes.

- Its focus on customer satisfaction drives continuous improvement in product design.

Shanghai Jurry’s expertise in PVC pipe production makes it a trusted partner for manufacturers seeking reliable extrusion solutions.

Key Features and Benefits of Leading Brands

Durability and Material Quality

Top manufacturers prioritize durability and material quality to ensure long-lasting performance. They utilize advanced materials like bi-metal liners for enhanced wear resistance and 45# steel cylinders for structural integrity. N00 nitriding steel improves corrosion resistance, while H6 or D11 materials offer exceptional wear resistance. For extreme conditions, HSS-PM steel provides unmatched durability.

| Material Type | Description |

|---|---|

| Bi-metal liner | Enhances durability and wear resistance |

| 45# steel cylinder | Provides structural integrity |

| N00 nitriding steel | Improves corrosion resistance |

| H6 or D11 | Offers high wear resistance |

| HSS-PM | Special steel for extreme conditions |

These materials ensure that parallel twin screw barrels withstand demanding applications, maintaining consistent performance over time.

Precision and Performance

Leading brands integrate advanced control systems to maximize precision and performance. These systems regulate critical parameters such as temperature, screw speed, and feed rate. Real-time monitoring ensures uniform material processing, reducing waste and improving product quality. This level of precision makes parallel twin screw barrels indispensable for industries requiring consistent results.

Customization Options

Manufacturers offer extensive customization options to meet diverse industry needs. Customers can select specific screw designs, barrel geometries, and material compositions tailored to their applications. For instance, specialized configurations for PVC pipe production ensure efficient processing of PVC compounds. This flexibility allows businesses to optimize their extrusion processes for maximum efficiency.

After-Sales Support and Warranty

Reliable after-sales support and comprehensive warranties set top brands apart. Manufacturers provide technical assistance, maintenance services, and replacement parts to ensure uninterrupted operations. Warranties covering material defects and performance issues give customers peace of mind, reinforcing trust in the product’s quality.

Applications of Parallel Twin Screw Barrels

Plastic Extrusion

Parallel twin screw barrels play a pivotal role in plastic extrusion processes. Their design enhances efficiency by reducing residence time, which accelerates material processing. The self-cleaning feature minimizes product waste, contributing to sustainability efforts. Flexibility in operating parameters allows manufacturers to adjust extrusion rates and mixing functions with ease.

- Reduced residence time improves throughput and energy efficiency.

- Self-cleaning mechanisms decrease waste, supporting eco-friendly operations.

- Adjustable operating parameters optimize extrusion rates and mixing functions.

- Enhanced mixing capabilities ensure uniform compounding of materials.

Coperion’s ZSK Mc¹⁸ Twin Screw Extruder exemplifies these benefits. Its high torque performance and precision manufacturing make it ideal for engineering plastics, delivering consistent results while conserving energy.

Food Processing

Parallel twin screw barrels are indispensable in food processing applications. Their ability to texturize proteins effectively stems from the unique design of two internal rotating screws. These screws align and flow materials uniformly, ensuring consistent product quality.

- The extruder’s design supports precision manufacturing, crucial for food-grade applications.

- Energy-efficient operations reduce costs while maintaining high throughput.

- Enhanced mixing capabilities allow for the production of diverse food products, including textured proteins and snacks.

Manufacturers rely on these systems to meet stringent food safety standards while achieving optimal production efficiency.

Chemical and Pharmaceutical Industries

Chemical and pharmaceutical industries benefit from the versatility of parallel twin screw barrels. These systems handle complex materials with precision, ensuring uniform mixing and compounding. Their adaptability to various operating conditions makes them suitable for producing specialty chemicals and pharmaceutical formulations.

- Uniform mixing ensures consistent product quality.

- Adjustable parameters accommodate diverse material properties.

- Self-cleaning features reduce contamination risks, critical for pharmaceutical applications.

Parallel twin screw barrels streamline production processes, enabling manufacturers to meet high-quality standards while maintaining operational efficiency.

How to Choose the Right Manufacturer

Selecting the right manufacturer for extrusion equipment is a critical decision that impacts production efficiency and product quality. By evaluating key factors such as performance, pricing, customization, and customer feedback, businesses can make informed choices that align with their operational goals.

Assessing Performance and Reliability

Performance and reliability are the cornerstones of any high-quality extrusion system. Manufacturers should demonstrate a proven track record of delivering durable and efficient equipment. Businesses can evaluate this by examining the materials used in the construction of the equipment, such as wear-resistant alloys or corrosion-resistant coatings. Additionally, testing the equipment under real-world conditions provides insights into its operational stability and consistency.

Tip: Look for manufacturers that offer performance certifications or third-party testing reports. These documents validate the reliability of their products.

Comparing Pricing and Value

While cost is an important consideration, it should not overshadow the value offered by the manufacturer. A lower price may seem attractive initially, but it could result in higher maintenance costs or reduced efficiency over time. Instead, businesses should focus on the total cost of ownership, which includes factors like energy consumption, maintenance requirements, and lifespan.

| Factor | Description | Importance |

|---|---|---|

| Initial Cost | Upfront price of the equipment | Helps determine budget feasibility |

| Maintenance Costs | Expenses for upkeep and repairs | Affects long-term affordability |

| Energy Efficiency | Power consumption during operation | Reduces operational costs |

| Equipment Lifespan | Durability and longevity of the product | Ensures long-term value |

By comparing these factors, businesses can identify manufacturers that offer the best balance between cost and value.

Evaluating Customization Capabilities

Customization plays a vital role in meeting specific production requirements. Leading manufacturers provide tailored solutions, such as unique screw designs or specialized barrel geometries, to optimize performance for particular applications. For example, a manufacturer specializing in PVC pipe production may offer a Parallel Twin Screw Barrel designed to handle PVC compounds efficiently.

When evaluating customization capabilities, businesses should consider the following:

- Availability of tailored designs for specific materials or processes.

- Flexibility in modifying existing equipment to meet unique needs.

- Support for integrating advanced technologies, such as automation or IoT features.

Manufacturers that prioritize customization enable businesses to enhance their production processes and achieve greater efficiency.

Importance of Customer Reviews and Testimonials

Customer reviews and testimonials offer valuable insights into a manufacturer’s reputation and product quality. These firsthand accounts highlight the strengths and weaknesses of the equipment, as well as the level of customer support provided. Positive reviews often indicate consistent performance, reliable after-sales service, and overall customer satisfaction.

Note: Pay attention to reviews that mention long-term usage and post-purchase support. These factors are critical for ensuring a smooth operational experience.

In addition to online reviews, businesses can request references from the manufacturer. Speaking directly with other customers provides an opportunity to ask specific questions about their experiences.

By thoroughly assessing these factors, businesses can confidently select a manufacturer that aligns with their operational needs and long-term goals.

Emerging Trends in the Parallel Twin Screw Barrel Industry

Focus on Energy Efficiency

Energy efficiency has become a critical focus in the parallel twin screw barrel industry. Manufacturers are designing systems that consume less power while maintaining high performance. Advanced screw designs and optimized barrel geometries reduce energy loss during material processing. These innovations not only lower operational costs but also contribute to environmental sustainability.

Energy-efficient systems also align with global efforts to reduce carbon footprints. By minimizing energy consumption, manufacturers can meet stringent environmental regulations. This trend highlights the industry’s commitment to balancing productivity with ecological responsibility.

Integration of Automation and Smart Technology

The integration of automation and smart technology is revolutionizing the extrusion industry. Companies are adopting Industry 4.0 technologies to enhance operational efficiency and precision. Smart systems equipped with IoT capabilities enable real-time monitoring and control of critical parameters such as temperature and screw speed. This ensures consistent product quality and reduces downtime.

| Key Points | Description |

|---|---|

| Development of Biodegradable Plastics | There is a growing focus on sustainable manufacturing practices leading to the rise of biodegradable plastics. |

| Adoption of Industry 4.0 Technologies | Companies are integrating smart manufacturing solutions to enhance efficiency and productivity. |

| Demand for Efficient Production Techniques | Automation and IoT are driving the need for more efficient production methods in the industry. |

Automation also supports predictive maintenance, allowing manufacturers to address potential issues before they escalate. This reduces repair costs and extends equipment lifespan, making it a valuable investment for businesses.

Use of Sustainable Materials

Sustainability is shaping the future of parallel twin screw barrels. Manufacturers are increasingly using eco-friendly materials to produce barrels and screws. Biodegradable plastics and recyclable components are gaining popularity, reflecting the industry’s shift toward greener practices. These materials reduce waste and promote a circular economy.

The use of sustainable materials also enhances brand reputation. Companies adopting these practices demonstrate their commitment to environmental stewardship, which resonates with eco-conscious consumers. This trend underscores the industry’s role in fostering a sustainable future while meeting production demands.

Leading brands like Coperion, Leistritz, and KraussMaffei dominate the extrusion industry with innovative solutions. Their technological advancements and diverse product portfolios enhance extrusion processes globally. Businesses benefit from their regional presence, strong sales performance, and reliable systems. Choosing a trusted manufacturer ensures optimal results for applications requiring a Parallel Twin Screw Barrel.

FAQ

What is the difference between parallel and conical twin screw barrels?

Parallel twin screw barrels feature side-by-side screws for uniform mixing. Conical designs taper for enhanced pressure, ideal for specific extrusion applications.

How do I maintain a parallel twin screw barrel?

Regular cleaning prevents material buildup. Lubricate moving parts and inspect for wear. Follow manufacturer guidelines for optimal performance and longevity.

Can parallel twin screw barrels handle multiple materials?

Yes, they process diverse materials like plastics, rubber, and food compounds. Customization ensures compatibility with specific applications.

Post time: Jun-12-2025