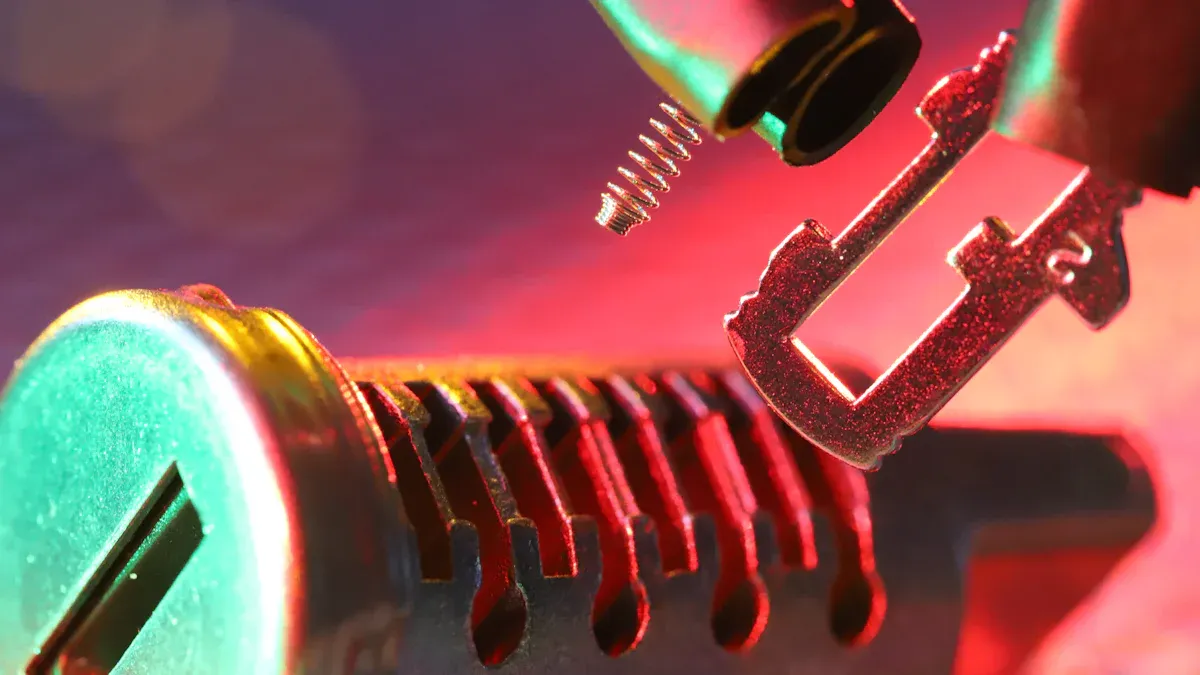

Selecting the right Parallel Twin Screw Barrel is crucial for achieving optimal polymer processing. The configuration of the parallel twin screw and barrel significantly enhances melting and mixing efficiency. This directly impacts the quality of the extrudate produced. Aligning barrel specifications with application requirements ensures better performance and efficiency in processes like PVC pipe production parallel twin screw. Additionally, utilizing a Twin Plastic Screw Barrel can further improve the overall processing capabilities and product quality.

Key Features of Parallel Twin Screw Barrels

Barrel Material

The choice of barrel material plays a vital role in the performance and longevity of a parallel twin screw barrel. Different materials offer unique advantages, impacting wear resistance and overall processing efficiency. Here are some common materials used in manufacturing parallel twin screw barrels along with their respective advantages:

| Material Type | Advantages |

|---|---|

| Double Alloy | Extends service life of the screw barrel |

| Reasonable Screw Design | Enhances plasticizing effect and output, ensuring stable extrusion |

| Large Load-Bearing Torque | Reduces energy consumption and avoids defects in extrusion processes |

Selecting the right material can significantly influence the wear resistance of the barrel. For instance, Xaloy X-800 is ideal for highly filled resins requiring extreme abrasion resistance, while AISI 4140 serves well for general-purpose unfilled resins. Understanding the specific application requirements helps in making an informed choice.

Screw Design

Screw design is another critical feature that affects the mixing efficiency of a parallel twin screw barrel. The geometry and configuration of the screws determine how well materials blend during processing. Two primary screw designs exist: co-rotating and counter-rotating.

| Screw Design | Characteristics | Mixing Efficiency Impact |

|---|---|---|

| Co-rotating | Screws rotate in the same direction, resulting in high shear rates and excellent dispersive and distributive mixing. | Provides good self-cleaning properties and is ideal for applications requiring product homogeneity, such as color masterbatches. |

| Counter-rotating | Screws rotate in opposite directions, offering good conveying characteristics and high-pressure build-up. | Generally yields lower shear rates and mixing efficiency compared to co-rotating designs, suitable for high filler loadings in PVC applications. |

The choice between these designs depends on the specific requirements of the application. Co-rotating screws are often preferred for their superior mixing capabilities, while counter-rotating screws may be more suitable for certain high-torque applications.

Length-to-Diameter Ratio

The length-to-diameter (L/D) ratio is crucial in determining the performance of a parallel twin screw barrel. This ratio influences the residence time of the material within the barrel, which directly affects mixing, melting, and chemical reactions. A higher L/D ratio generally leads to longer residence times, enhancing product quality.

In applications such as pharmaceutical hot melt extrusion, precise control over the L/D ratio is essential for maintaining drug stability and achieving uniform dispersion. Conversely, in food or biodegradable polymer research, larger screw diameters and higher L/D ratios can improve throughput and structural development.

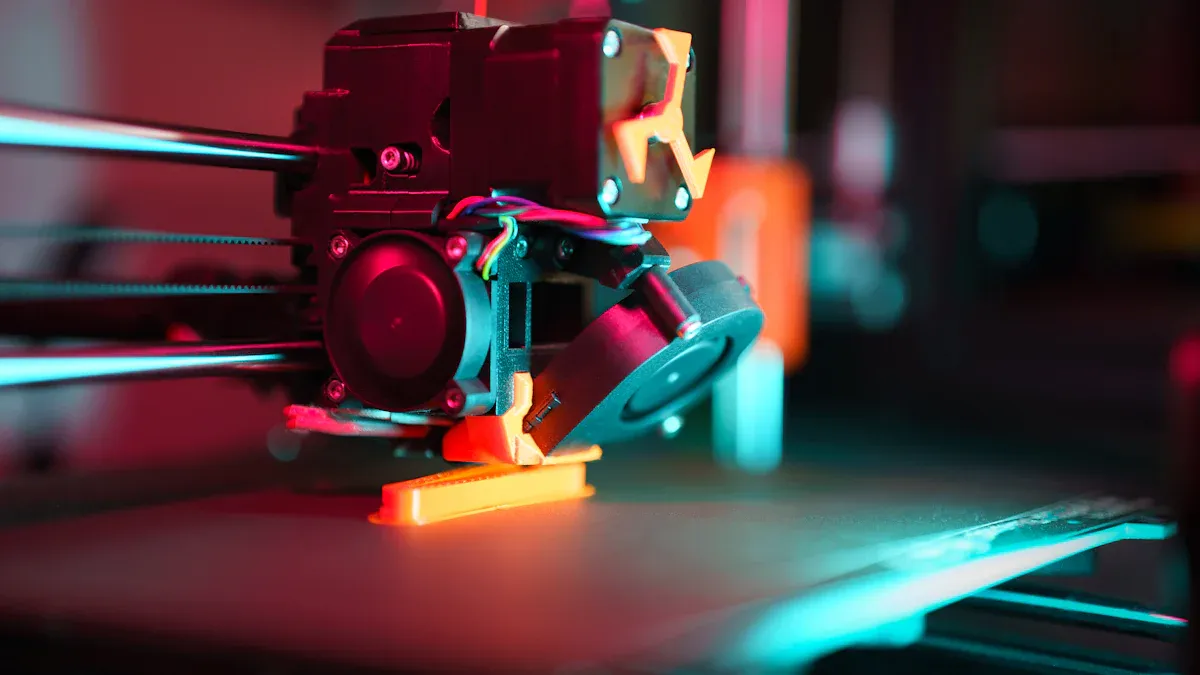

Recent advancements in parallel twin screw barrel technology have focused on optimizing these parameters to enhance processing efficiency. Innovations include increased automation and smart manufacturing techniques, which allow for real-time monitoring and data analytics, further improving the overall performance of the parallel twin screw barrel.

Factors to Consider When Choosing a Parallel Twin Screw Barrel

Material Compatibility

Material compatibility is essential when selecting a parallel twin screw barrel. Different polymers have unique processing requirements, and the wrong barrel material can lead to significant issues. For example, glass fiber-reinforced plastics require specialized barrel materials to prevent wear and ensure efficient processing.

Consider the following factors that can affect compatibility:

| Factor | Description |

|---|---|

| Machine Model and Brand | Different manufacturers have unique specifications for barrel length, mounting style, and screw design. |

| Processing Material | Specific materials like glass fiber–reinforced plastics require specialized barrel materials. |

| Design Parameters | The screw diameter and length-to-diameter ratio impact the efficiency of plasticizing. |

| Heating and Cooling Systems | Incompatibility can lead to overheating or inadequate temperature control during processing. |

Understanding these factors helps in selecting a barrel that aligns with the specific requirements of the polymer being processed.

Design Specifications

Design specifications play a crucial role in the performance of a parallel twin screw barrel, especially for high-viscosity polymers. The right design ensures optimal mixing and melting, which directly affects product quality. Key specifications to consider include:

| Specification Type | Description |

|---|---|

| Material Quality | High-quality raw materials ensure continuous, stable, high-yield damage resistance ability. |

| Surface Treatment | Nickel-based or tungsten carbide alloy surface treatments improve wear resistance and longevity. |

| Production Processes | Multiple heat treatments (quenching, tempering, nitriding) are essential to meet technical requirements. |

These specifications ensure that the barrel can handle the demands of the application while maintaining efficiency and durability.

Manufacturer Reputation

The reputation of the manufacturer is another critical factor in selecting a parallel twin screw barrel. A reputable manufacturer typically adheres to high standards in production and customer service. Consider the following criteria when evaluating manufacturers:

- Quality of Raw Materials: High-quality twin screw barrels are made from superior raw materials that ensure durability and performance.

- Surface Treatment: Effective surface treatments, such as spray-welding with nickel-based or tungsten carbide alloys, enhance wear resistance and longevity.

- Production Processes: The manufacturing process should include multiple heat treatments to meet technical specifications.

- Research and Development Capabilities: A reputable manufacturer should have strong R&D capabilities to innovate and improve product designs based on customer needs.

Additionally, after-sales support and warranty coverage are vital. Ensure that the manufacturer provides technical assistance and maintenance services to address any issues that may arise during operation.

Tip: Always check for customer reviews and testimonials to gauge the reliability of the manufacturer.

By considering these factors, one can make an informed decision when selecting a parallel twin screw barrel that meets specific application needs.

Practical Tips for Selecting a Parallel Twin Screw Barrel

Assessing Application Needs

Before selecting a parallel twin screw barrel, it is essential to assess the specific needs of the application. Consider the type of materials being processed, the desired output, and the required quality standards. Understanding these factors helps in determining the appropriate specifications for the barrel.

Consulting with Experts

Consulting with specialists enhances understanding of extrusion equipment. Experts provide tailored advice based on specific project needs, ensuring the right extruder is selected to meet design, production, and quality standards. Utilizing expert knowledge allows for informed decisions that incorporate the latest industry trends. This approach leads to better alternatives for achieving project objectives.

Evaluating Cost vs. Performance

When evaluating cost versus performance, several factors come into play:

- Material Expenses: Consider the wear resistance and longevity of materials like hardened steels or specialty alloys. Higher initial costs may lead to better durability.

- Labor Charges: Account for skilled labor needed for precise removal of lining inserts and indirect costs from production downtime.

- Machining and Surface Treatment: Evaluate costs associated with machining for a proper fit and any surface treatments that enhance performance.

- Operational Downtime: Factor in the time lost during replacement, which can disrupt production schedules.

| Type of Barrel | Initial Costs | Long-term Operational Costs | Efficiency Benefits |

|---|---|---|---|

| High-Performance Twin Screw | Higher | Lower due to reduced energy consumption and maintenance needs | Enhanced efficiency leading to cost savings |

| Standard Twin Screw | Lower | Higher due to inefficiencies and frequent maintenance requirements | Less efficient, leading to increased costs |

By carefully considering these aspects, manufacturers can make informed decisions that balance upfront costs with long-term operational efficiency.

Choosing the right parallel twin screw barrel is essential for optimizing polymer processing. Proper selection enhances throughput capability and mixing efficiency, which is crucial for large-scale production. Informed decision-making leads to improved material distribution and reduced energy costs.

Consider exploring resources such as:

- Advanced materials and coatings for durability and efficiency.

- Smart sensors and IoT technology for real-time monitoring and predictive maintenance.

- Case studies demonstrating enhanced process stability and output quality.

By evaluating all factors and seeking expert advice, manufacturers can ensure they meet their specific application needs effectively.

FAQ

What is a parallel twin screw barrel?

A parallel twin screw barrel is a component used in extrusion processes. It consists of two parallel screws that enhance mixing and melting of materials.

How do I determine the right barrel size?

To determine the right barrel size, assess the material type, desired output, and specific application requirements. Matching these factors ensures optimal performance.

Why is material compatibility important?

Material compatibility is crucial to prevent wear and ensure efficient processing. Incompatible materials can lead to defects and reduced product quality.

Post time: Sep-26-2025