A Parallel Twin Screw Barrel delivers consistent performance in industrial settings. Engineers evaluate quality using metrics like screw speed, residence time, torque values, and screw configuration. The Twin Plastic Screw Barrel, Conical Twin Screw Extruder Screw Barrels, and parallel twin screw and barrel systems must meet high standards to ensure durability and adaptability.

| Metric | Description |

|---|---|

| Screw speed | Affects material throughput and torque. |

| Residence time | Influences thermal exposure and risk of material degradation. |

| Torque values | Relates to material load and mechanical stress. |

| Screw configuration | Optimized for material type to improve mixing and efficiency. |

Material Quality in Parallel Twin Screw Barrel

High-Grade Alloys for Strength

Manufacturers select high-grade alloys to ensure the Parallel Twin Screw Barrel withstands demanding industrial environments. The choice of alloy directly influences the barrel’s strength and durability. Engineers often use materials such as 38CrMoAlA, 42CrMo, and 9Cr18MoV. These alloys provide a solid foundation for the barrel and screw, enhancing resistance to wear and mechanical stress.

| Alloy Type | Description |

|---|---|

| 38CrMoAlA | Basic material for screw, enhanced with bimetallic alloy for longevity |

| 42CrMo | High-quality alloy steel used in barrels |

| 9Cr18MoV | Another high-grade alloy for durability |

Different alloy combinations offer unique advantages. For example, 45 Steel with C-Type Liner Bushing delivers cost-effective wear resistance. Nitrided Steel 38CrMoAla provides high hardness and corrosion resistance. HaC Alloy excels in environments with fluoroplastics, while 316L Stainless Steel suits food industry applications.

| Alloy Type | Key Properties |

|---|---|

| 45 Steel + C-Type Liner Bushing | Cost-effective, wear-resistant alloy liners |

| 45 Steel + α101 | High hardness (HRC 60-64), wear resistance, suitable for glass fiber |

| Nitrided Steel 38CrMoAla | High hardness, corrosion resistance, durable structure |

| HaC Alloy | Superior corrosion resistance, ideal for fluoroplastics |

| 316L Stainless Steel | Excellent corrosion and rust resistance, suitable for food industry |

| Cr26, Cr12MoV Liner | Ultra-high chromium powder alloy, exceptional wear resistance |

| Powder Nickel-Based Alloy Liner | Combined wear and corrosion resistance, suitable for high-demand environments |

| Imported Powder Metallurgy Liner | Superior performance in corrosive and wear-intensive conditions |

Impact on Service Life and Output

Material quality plays a vital role in the service life of a Parallel Twin Screw Barrel. High-grade alloys resist abrasion and corrosion, which extends operational lifespan. The design of intermeshing screws generates strong shear forces, blending materials thoroughly. This process ensures even mixing and prevents thermal degradation of sensitive polymers. Consistent temperature control throughout the barrel maintains product quality.

Tip: Incorporating venting or vacuum zones in twin screw extruders helps remove volatile substances or air from the material. This feature improves the consistency and reliability of the final output.

A Parallel Twin Screw Barrel with superior material quality delivers stable performance and high-quality products. Manufacturers achieve reliable output by maintaining strict standards in alloy selection and barrel construction.

Precision Engineering of Parallel Twin Screw Barrel

Tight Tolerances and Accuracy

Precision engineering sets the foundation for reliable performance in a Parallel Twin Screw Barrel. Manufacturers use advanced CNC equipment and strict quality control to achieve tight tolerances. These tolerances ensure that each component fits perfectly and operates smoothly. The following table shows typical industry standards for manufacturing tolerances:

| Component | Tolerance |

|---|---|

| Screw Outer Diameter | +/- 0.001 inches per inch of diameter |

| Flight Clearance | 0.004 to 0.006 inches per inch of diameter |

| Screw Length | +/- 1/32 of an inch |

| Barrel Internal Diameter | +/- 0.001 inches per inch of diameter |

| Barrel Straightness | +/- 0.001 inches per inch of length |

| Barrel Concentricity | +/- 0.001 inches |

Accurate machining helps prevent leaks, reduces vibration, and maintains consistent pressure. These factors contribute to stable operation and longer equipment life.

Consistent Product Quality

Precision engineering leads to consistent product quality. Twin screw extruders deliver superior results for products with strict quality requirements. They mix and degas materials efficiently, which reduces defects and improves output. The following points highlight how tight tolerances improve product quality:

- Enhanced mixing and degassing capabilities result in fewer defects.

- Even distribution of polymers, additives, fillers, and colorants ensures uniform properties across batches.

Operational efficiency also benefits from precision engineering. The table below outlines key aspects and their contributions:

| Aspect | Contribution to Efficiency |

|---|---|

| High Throughput | Increases productivity with better material conveying and melting |

| Precise Control | Enables fine-tuning for consistent, high-quality output |

| Improved Heat Transfer | Facilitates accurate temperature control for desired material properties |

| Optimal Configuration | Tailors extrusion systems to specific processing needs, enhancing performance |

Precision engineering in a Parallel Twin Screw Barrel ensures every batch meets high standards, supporting manufacturers in delivering reliable products.

Wear Resistance in Parallel Twin Screw Barrel

Abrasion Protection

Manufacturers design barrels to resist abrasion from tough materials. They use advanced surface treatments to strengthen the barrel and screw. These treatments help protect against constant friction and contact with abrasive polymers or additives. The following table shows common surface treatments that improve wear resistance:

| Treatment Type | Description | Source |

|---|---|---|

| Nickel-based alloy powder | Spray-welded to improve wear resistance and prolong service life. | Lesun Screw |

| Tungsten carbide alloy powder | Enhances wear resistance significantly. | Lesun Screw |

| Surface nitriding | Increases surface hardness to improve wear resistance. | Lesun Screw |

These treatments create a tough outer layer. The barrel can handle high loads and abrasive compounds without losing performance. Engineers select the right treatment based on the processing material and production demands.

Note: Surface nitriding increases hardness, which helps the barrel resist scratches and wear during long production runs.

Prolonged Operational Life

Wear resistance plays a key role in extending the operational life of a Parallel Twin Screw Barrel. When the barrel resists abrasion, it maintains its shape and function over time. This durability reduces the need for frequent maintenance and replacement. In high-volume production, strong wear resistance means fewer adjustments to operating parameters. The barrel continues to deliver consistent quality and energy efficiency.

Operators monitor wear levels to plan maintenance before problems arise. Recognizing when adjustments no longer improve output helps schedule timely replacements or rebuilds. This approach keeps production running smoothly and minimizes downtime.

A barrel with excellent wear resistance supports reliable manufacturing and lowers long-term costs. Companies benefit from stable output and fewer interruptions.

Corrosion Resistance for Parallel Twin Screw Barrel

Handling Aggressive Compounds

Manufacturers design Parallel Twin Screw Barrel systems to process a wide range of materials, including those with aggressive chemical properties. Some plastics and additives contain corrosive agents that can damage the inner surfaces of the barrel. To protect against these threats, engineers apply specialized coatings that resist chemical attack and wear. The following table shows common corrosion-resistant coatings and their best use cases:

| Coating Type | Key Properties | Best Use Case |

|---|---|---|

| Chromium Nitride (CrN) | Excellent corrosion resistance and wear protection; ideal for corrosive materials like PVC. | Processing corrosive materials |

| Titanium Nitride (TiN) | High hardness and superior wear resistance; reduces friction. | Standard plastic processing operations |

| Titanium Aluminum Nitride (TiAlN) | High temperature stability; suitable for high-speed or high-temperature applications. | Fiber production or flame-retardant materials |

These coatings help the barrel withstand harsh environments and maintain performance. Operators select the right coating based on the type of compound and the demands of the production process.

Lower Maintenance Demands

Corrosion resistance plays a key role in reducing maintenance needs. When the barrel resists chemical wear, it lasts longer and requires fewer repairs. Corrosion wear from auxiliary materials can directly affect the inner wall of the cylinder, leading to a reduced lifespan of the barrel. Using more wear-resistant and corrosion-resistant materials extends the service life of extruder components and reduces maintenance frequency.

- Enhanced corrosion resistance materials lead to longer service life.

- Longer service life results in extended maintenance intervals.

- Non-corrosion-resistant materials increase the frequency of inspections and replacements.

Operators benefit from fewer interruptions and lower costs. They spend less time on inspections and replacements, which keeps production running smoothly. Choosing corrosion-resistant barrels supports efficient manufacturing and reliable output.

Barrel Cooling System in Parallel Twin Screw Barrel

Efficient Temperature Regulation

Engineers design the barrel cooling system to maintain precise temperature control during operation. The system uses both heating and cooling elements to achieve optimal results. Electric heaters and water jackets are common components embedded within the barrel. Operators can adjust the temperature at different zones along the barrel to match the requirements of each plastic material. This flexibility allows for consistent melting and mixing.

- Temperature control system provides accurate regulation.

- Electric heaters and water jackets work together for balanced heating and cooling.

- Multiple zones enable tailored temperature adjustments for various materials.

A well-regulated temperature ensures that polymers do not degrade or burn. Consistent temperature management leads to higher product quality and stable output.

Preventing Overheating and Deformation

Continuous operation can cause barrels to overheat and deform. Manufacturers address this challenge by using modular barrels with internal cartridge heaters and cooling bores. These cooling bores sit close to the liner, maximizing the cooling effect. The Parallel Twin Screw Barrel often features three to five barrel cooling zones, which help maintain steady temperatures during production.

- Modular barrels improve cooling efficiency.

- Internal cooling bores prevent overheating in high-speed operations.

- Multiple cooling zones provide effective temperature control.

- Screw cooling power of 3kw maintains consistent performance.

- Barrel hardness of HRC58-62 resists wear and deformation under pressure.

Effective cooling protects the barrel from damage and extends its service life. Operators benefit from reliable performance and reduced maintenance needs.

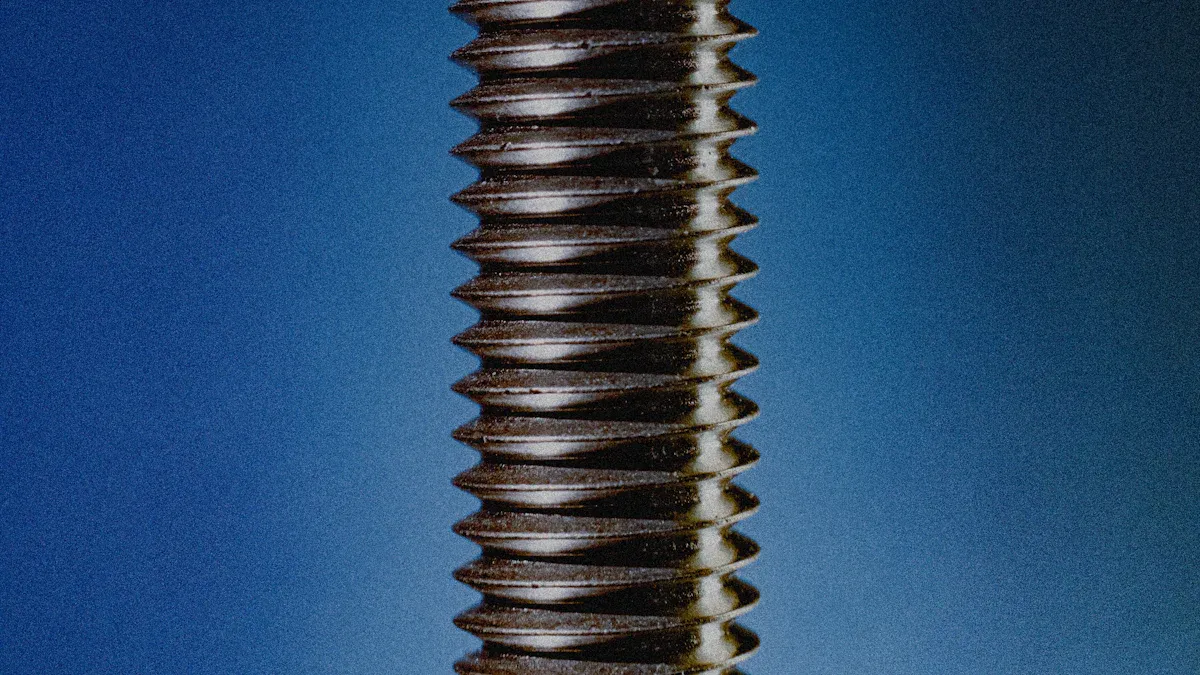

Screw Design in Parallel Twin Screw Barrel

Optimized Geometry for Mixing and Dispersion

Engineers focus on screw geometry to achieve superior mixing and dispersion. The shape of the screw channel influences how materials move and blend inside the barrel. A figure-of-eight design stands out as the most effective geometry. This design reduces throughput time by over 40% compared to other shapes. It also maintains high mixing quality, making it a preferred choice in many industries.

| Barrel Geometry | Effectiveness in Material Transport | Mixing Quality | Notes |

|---|---|---|---|

| Figure-of-eight design | Most effective, reduces throughput time by over 40% | Similar to others | Industry-accepted design for optimal performance. |

| Rounded sides with flat center | 22% less effective than figure-of-eight | Similar to others | Less net force acting on particles, but worse at conveying. |

A well-optimized screw geometry ensures that polymers, fillers, and additives blend evenly. This leads to consistent product quality and fewer defects.

Adaptability to Various Processes

Screw design adaptability allows manufacturers to process a wide range of materials. Engineers can tailor mixing, shear rates, and residence times for each application. This flexibility is essential for producing filled or reinforced plastics, profiles, and pipes.

- The design supports high stability and uniform shear distribution, which is crucial for continuous production.

- Parallel twin-screw extruders offer a long processing length, ideal for extensive mixing or devolatilization.

- The consistent diameter along the screw enables precise control over material properties and product quality.

A Parallel Twin Screw Barrel with adaptable screw design meets the needs of diverse manufacturing processes. Operators can achieve reliable results, whether producing standard products or specialized compounds.

Customization Options for Parallel Twin Screw Barrel

Tailored Solutions for Specific Applications

Manufacturers offer a wide range of customization options to meet the demands of different industries. Engineers design modular barrel systems using interchangeable sections. This approach allows them to configure the barrel for specific processes. Side feeders enable the addition of materials at precise points, improving flexibility. Venting ports help remove gases or moisture, which protects product quality. Liquid injection ports allow for the addition of liquids during processing. Modular screw designs use individual elements for functions such as conveying and mixing. These features support versatility and process control.

| Customization Option | Description |

|---|---|

| Modular Barrel Design | Interchangeable sections for tailored configurations |

| Side Feeders | Add materials at specific points for enhanced processing |

| Venting Ports | Remove gases or moisture during processing |

| Liquid Injection Ports | Add liquids at various stages |

| Modular Screw Design | Individual elements for conveying and mixing |

| Versatility | Process a wide range of materials across industries |

| Process Control | Precise control of parameters for consistent quality |

| Efficiency | High throughput and effective processing |

Flexibility for Unique Production Needs

Customization provides flexibility for manufacturers with unique production requirements. Engineers adjust screw pitch, flight depth, and mixing elements to match specific processing needs. The twin screw structure improves mixing uniformity and shortens production cycles. Companies benefit from higher throughput compared to single screw systems. These advantages allow manufacturers to increase production in less time and maintain consistent quality.

- Adjustable screw geometry meets diverse processing requirements.

- Enhanced mixing uniformity supports reliable product output.

- Higher throughput increases production efficiency.

A Parallel Twin Screw Barrel with tailored features helps manufacturers adapt to changing market demands and specialized applications.

Maintenance Accessibility of Parallel Twin Screw Barrel

Easy Cleaning and Inspection

Routine cleaning and inspection keep equipment running smoothly. Engineers design modern barrels with easy-access ports and modular sections. These features allow operators to reach internal surfaces quickly. Removable covers and inspection windows help workers check for residue or wear without disassembling the entire system. Clear access points also make it easier to remove buildup and prevent contamination.

Operators often use specialized brushes and cleaning agents for thorough maintenance. Visual checks identify early signs of wear or damage. Quick inspections reduce the risk of unexpected failures. A clean barrel ensures consistent product quality and extends the lifespan of the machinery.

Tip: Schedule regular inspections to catch minor issues before they become major problems.

Minimizing Downtime

Facilities rely on strict maintenance plans to keep production lines moving. A well-organized maintenance schedule includes cleaning, lubrication, and timely replacement of worn parts. These steps help maintain optimal performance and reduce the chance of sudden breakdowns.

- Establish a preventative maintenance schedule.

- Perform regular cleaning and lubrication.

- Replace worn parts before failure occurs.

A proactive approach keeps the Parallel Twin Screw Barrel operating efficiently. Less downtime means higher productivity and lower repair costs. Teams that follow a rigorous maintenance routine experience fewer interruptions and more reliable output.

Compatibility with Processing Materials in Parallel Twin Screw Barrel

Versatility Across Polymers and Additives

Manufacturers design modern barrels to handle a wide range of polymers and additives. They use modular screw elements and advanced temperature control systems. These features allow operators to switch materials quickly. Older barrels often struggle with new polymers or additives. Poor mixing and uneven melting can occur. Incompatibility sometimes leads to machine jams, which affects product quality. Newer systems support easy material changes and maintain high output standards.

- Modular screw elements improve adaptability.

- Advanced temperature control helps process different materials.

- Quick material switching reduces downtime.

- Reliable mixing prevents jams and defects.

Operators benefit from increased flexibility. They can produce various products without changing equipment.

Ensuring Consistent Output Quality

Compatibility with processing materials plays a key role in output quality. When materials mix evenly, the final product meets strict standards. Incompatible materials may separate during mixing. This phase separation can lower the overall mixing effect and reduce output quality. Consistent temperature control and screw design help prevent these issues. Manufacturers monitor the process to ensure uniform blending.

Note: Even distribution of polymers and additives leads to stable product properties and fewer defects.

A Parallel Twin Screw Barrel that supports diverse materials delivers reliable results. Companies achieve consistent quality and meet customer demands.

Manufacturer Support for Parallel Twin Screw Barrel

Technical Assistance and Training

Manufacturers provide a range of support services to help customers achieve the best results with their equipment. They offer project design and support, personalized training, and ongoing service. Staff members receive education to meet processing goals and improve efficiency. Process engineers evaluate existing equipment and develop extrusion solutions for specific needs. Companies also benefit from research and product development expertise, which helps optimize extrusion cooking and drying processes.

| Service Type | Description |

|---|---|

| Project Design & Support (CPS) | Addresses the entire scope of extrusion-based projects. |

| WEnger CARE Program | Customizable services, evaluations, and training programs. |

| Personalized Training | Ongoing educational support for staff. |

| Research & Product Development | Extensive knowledge in extrusion cooking and drying. |

| Service and Support | Comprehensive options for equipment maintenance and troubleshooting. |

Technical assistance and training ensure that operators understand how to use the Parallel Twin Screw Barrel effectively. These services help maintain high output quality and reduce the risk of errors.

Warranty and After-Sales Service

Warranty terms and after-sales service play a vital role in the total cost of ownership. Reliable technical support helps reduce downtime and keeps production running smoothly. Manufacturers provide spare parts to lower operational costs and prevent long delays. Operator training improves equipment reliability and efficiency. Warranty coverage influences long-term maintenance expenses and overall equipment performance.

- Reliable technical support reduces downtime.

- Spare parts availability lowers operational costs.

- Operator training enhances reliability and efficiency.

- Warranty terms affect maintenance costs and equipment reliability.

Strong manufacturer support gives companies confidence in their investment. They can rely on expert help and quick solutions when challenges arise.

Evaluating all 10 factors helps buyers choose a Parallel Twin Screw Barrel that offers lasting value. The table below shows how each factor shapes performance:

| Factor | Description |

|---|---|

| Material Selection | Forged with strong alloy steel for durability |

| Surface Treatment | Nitrided inner hole for high hardness |

| Machining Accuracy | Meets strict h8 level standards |

| Maintenance Practices | Quenched and tempered for reliability |

Efficiency improves through better thermal management, energy savings, and advanced maintenance. Industry experts guide buyers by offering technical support, custom options, and after-sales service.

FAQ

What industries use Parallel Twin Screw Barrels?

Manufacturers in plastics, rubber, chemical fiber, and food processing industries use Parallel Twin Screw Barrels for mixing, compounding, and extrusion tasks.

How often should operators perform maintenance on a twin screw barrel?

Operators should inspect and clean the barrel after each production cycle. Regular maintenance ensures stable performance and extends equipment life.

Can a Parallel Twin Screw Barrel handle different types of polymers?

Yes. Engineers design these barrels for versatility. They process a wide range of polymers and additives with consistent quality and efficiency.

Post time: Sep-01-2025