FEATURED

MACHINES

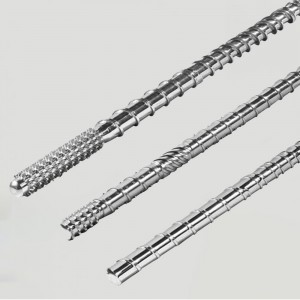

Conical twin screw barrel for SPC floor

JT screw barrel is committed to the study of SPC, stone plastic material properties, the development of high efficiency wear-resistant special screw barrel, to meet the needs of customers at home and abroad.

Jinteng Global

Jinteng screw and barrel series

In addition to Kington's headquarters in China, we currently have four overseas branches with a distribution network in 38 countries around the world

MISSION

JinTeng

The company has rich design experience and first-class management level, with large precision machining equipment for barrel and screw production, CNC equipment, and computer-controlled nitriding furnace and constant temperature quenching furnace for heat treatment, and equipped with advanced monitoring and testing equipment.